Early crack control method for prestressed concrete cast-in-place continuous box girder

A control method and concrete technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems affecting the durability and safety of bridge structures, crack prevention and control effects are not satisfactory, etc., and achieve the effect of convenient construction and good crack control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

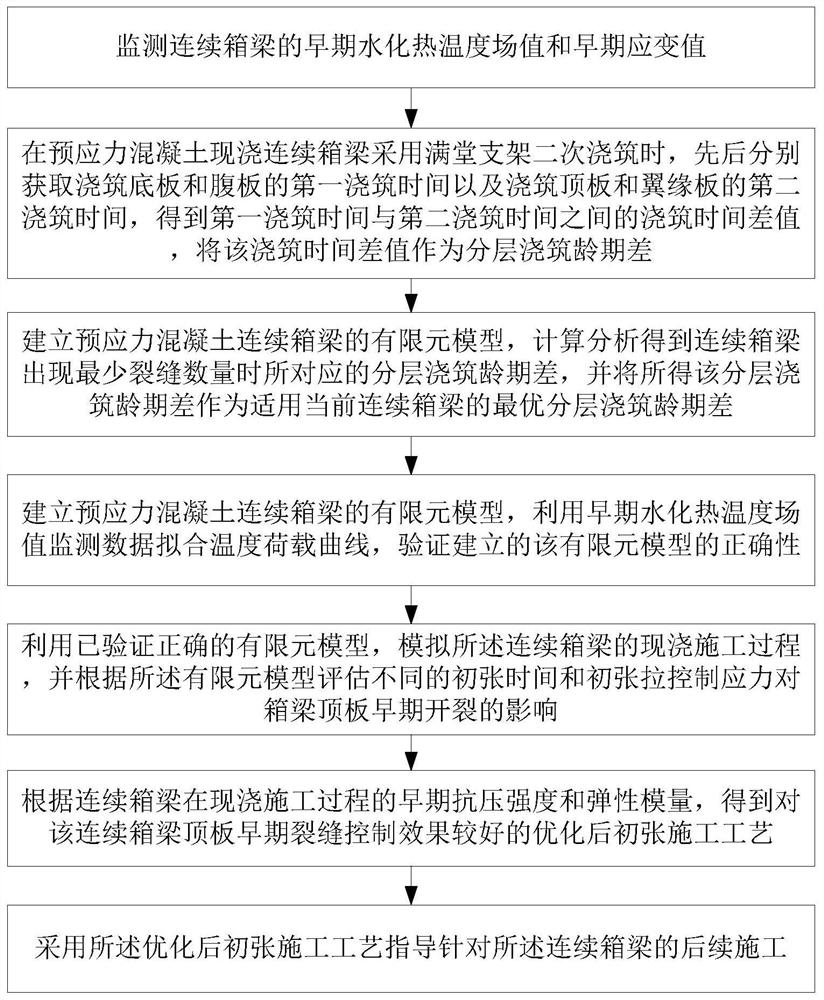

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] In this embodiment, an expressway connecting line project is taken as an example to illustrate the early crack control method of the prestressed concrete cast-in-place continuous box girder in the present invention.

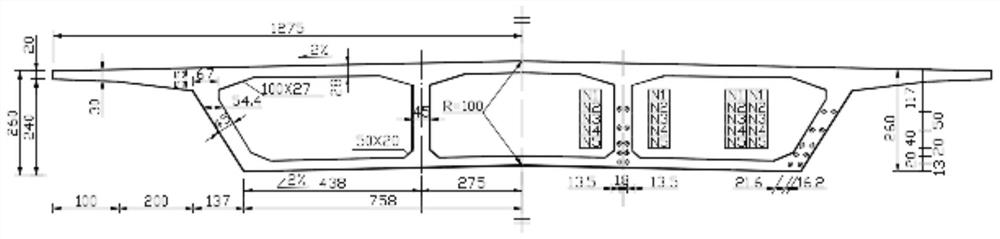

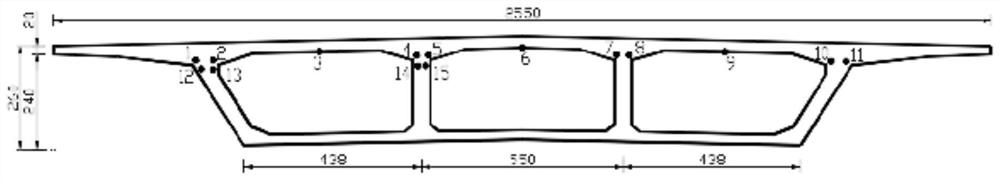

[0026] The expressway connecting line project adopts a continuous three-span prestressed concrete box girder with a span of 36m+42m+36m, a width of 25.5m, a single box with three rooms, and a beam height of 2.6m, using C50 concrete. Among them, the layout of the mid-span cross-section and prestressed steel tendon of the 42m span is as follows: figure 2 As shown, each bundle of prestressed steel strands is And select three sections S1, S2 and S3, these three sections are located at both ends and mid-span respectively, the section measuring points are divided into the measuring points at the junction of the roof and web, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com