Automatic chemical adding device and chemical adding method under foam drainage gas recovery well

A technology of automatic dosing and foam drainage, which is applied in chemical instruments and methods, mixers with rotary stirring devices, and mining fluids, etc., can solve the problems of foam not being defoamed in time, unable to fully drain, and insufficient foam volume, etc. To avoid waste of chemicals, avoid water flooding of gas production wells, and improve the efficiency of defoaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

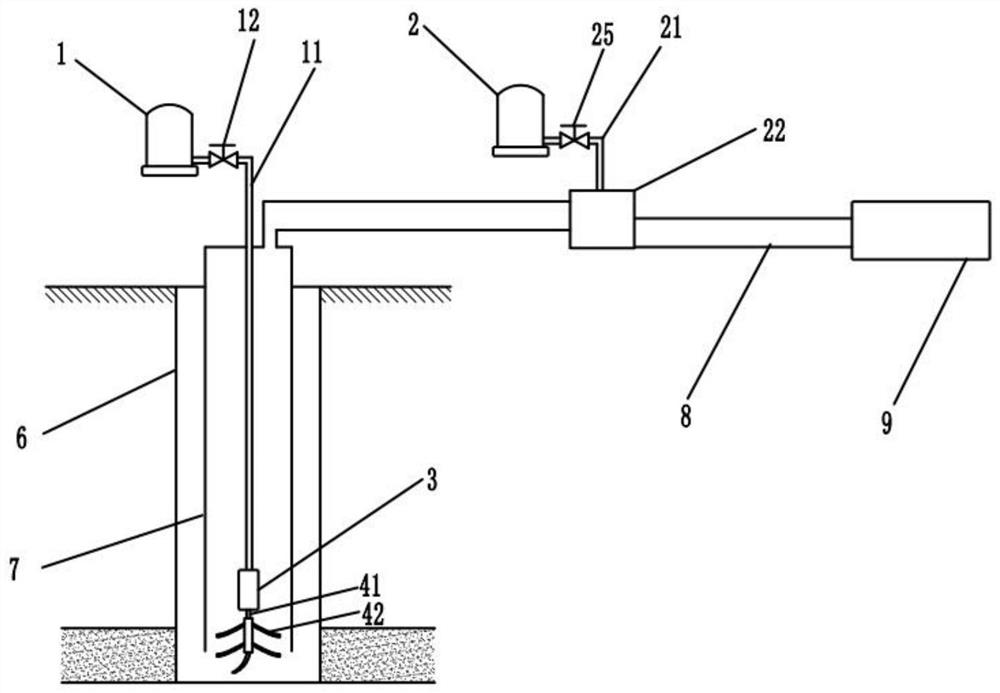

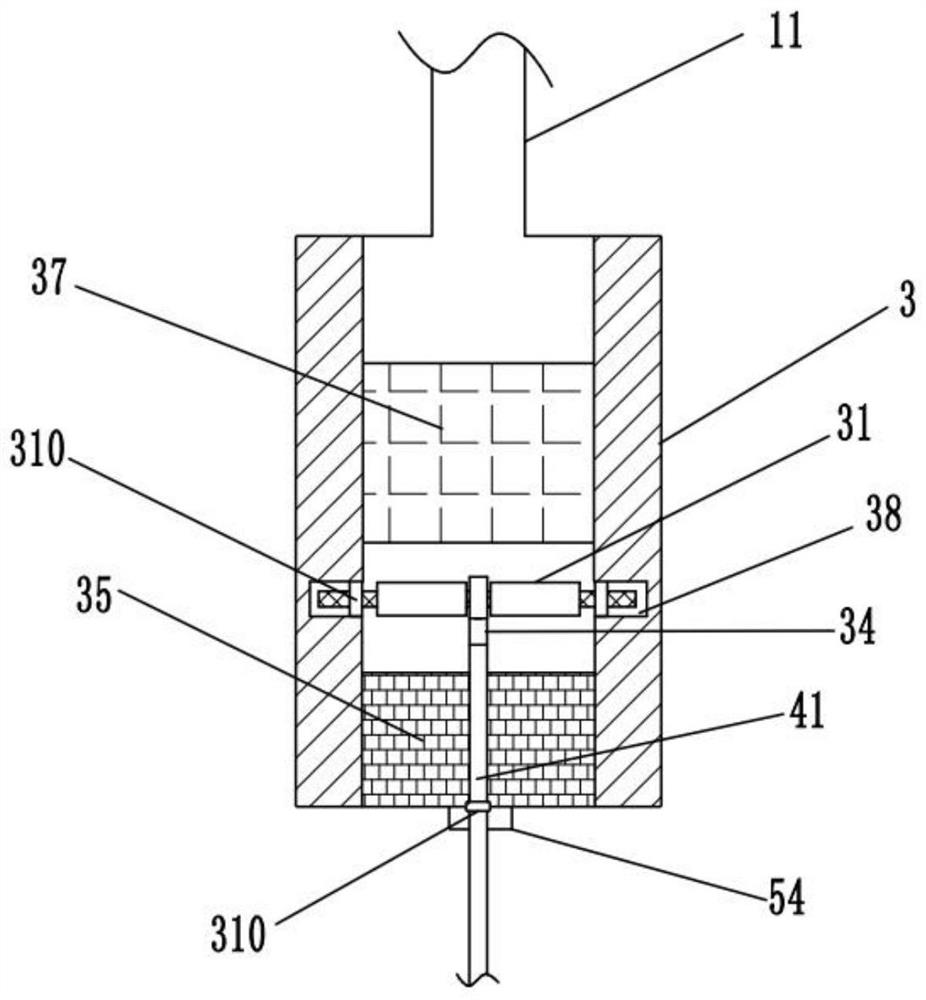

[0044] Refer to attached Figure 1-12 Shown is an automatic dosing device for a foam drainage gas production well, the foam drainage gas production well includes a casing 6 and an oil pipe 7, and the wellhead of the gas production well is provided with a drainage line 8, which is separated from the three-phase The product produced in the gas production well enters the three-phase separator 9 through the drainage pipeline 8.

[0045] Further, the automatic dosing device includes a foam discharge agent tank 1 and a defoamer tank 2, the foam discharge agent tank 1 and the defoamer tank 2 are both arranged above the ground, and the foam discharge agent Foam removal agent is housed in medicine tank 1, and defoamer is housed in described defoamer medicine tank 2.

[0046] Further, the bottom of the foaming agent medicine tank 1 is connected with a foaming agent feeding pipe 11, and the foaming agent feeding pipe 11 is provided with a valve 12 of the foaming agent feeding pipe. Med...

Embodiment 2

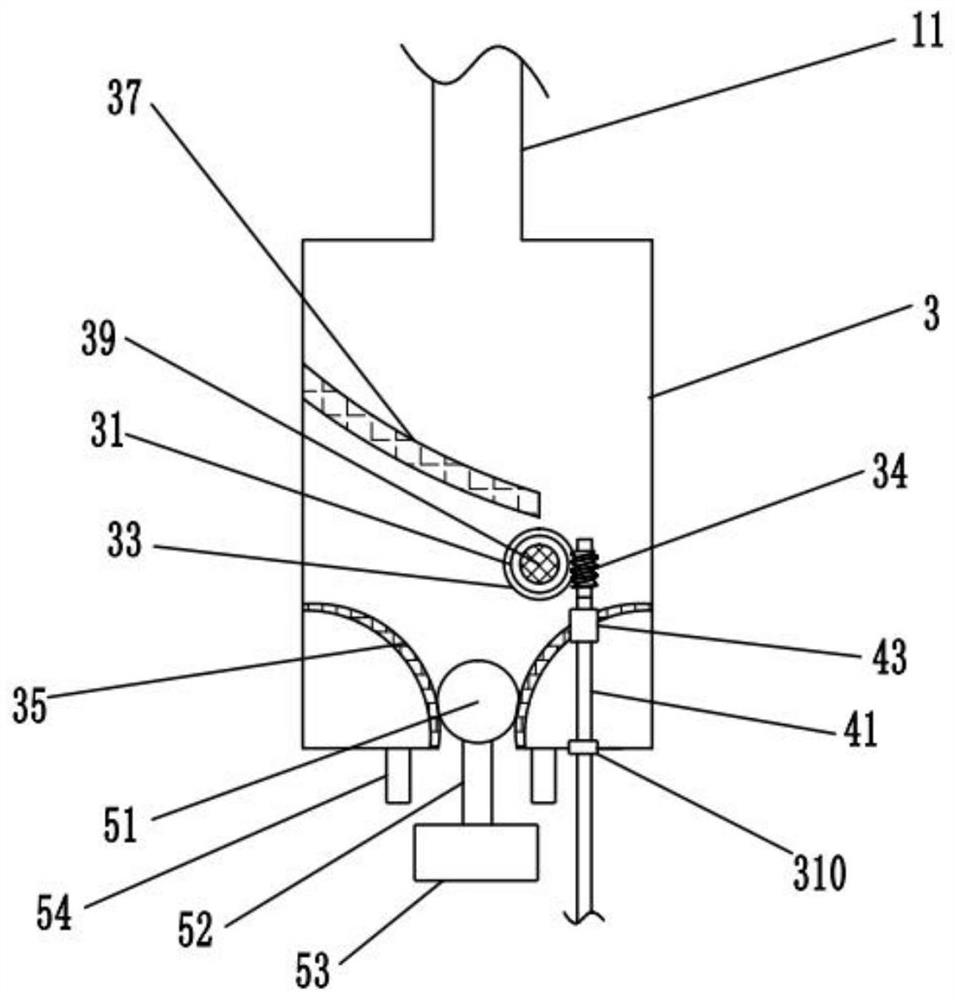

[0070] Refer to attached Figure 2-10 , and the attached Figure 12-14 , the foam drainage gas production downhole automatic dosing device in this embodiment is provided with a medicine dispensing tray 23 at the bottom of the defoamer dosing pipe 21, and the defoamer dosing pipe 21 communicates with the medicine dispensing disk 23 , the bottom of the drug distribution tray 23 is provided with a plurality of secondary dosing pipes 24, and the top of each of the secondary dosing pipes 24 communicates with the drug distribution tray 23, and each of the secondary dosing pipes The bottoms of the pipes 24 are all in communication with the defoaming chamber 22, and the defoamer flows into the drug distribution tray 23 from the defoamer dosing pipe 21, then enters different secondary dosing pipes 24, and then flows into the defoaming chamber 22 in.

[0071] Further, in the defoaming chamber 22, two herringbone-shaped splitter plates 221 are provided at the bottom of each of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com