Hydraulic anchor drill rig and three-working-position propelling beam thereof

A technology of advancing beam and three-station, applied in the fields of tunnel construction machinery and mining, can solve the problems of unmentioned angle error, heavy advancing beam, complicated operation, etc., and achieve the lifting rate, continuous rock drilling and anchoring process, and good economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

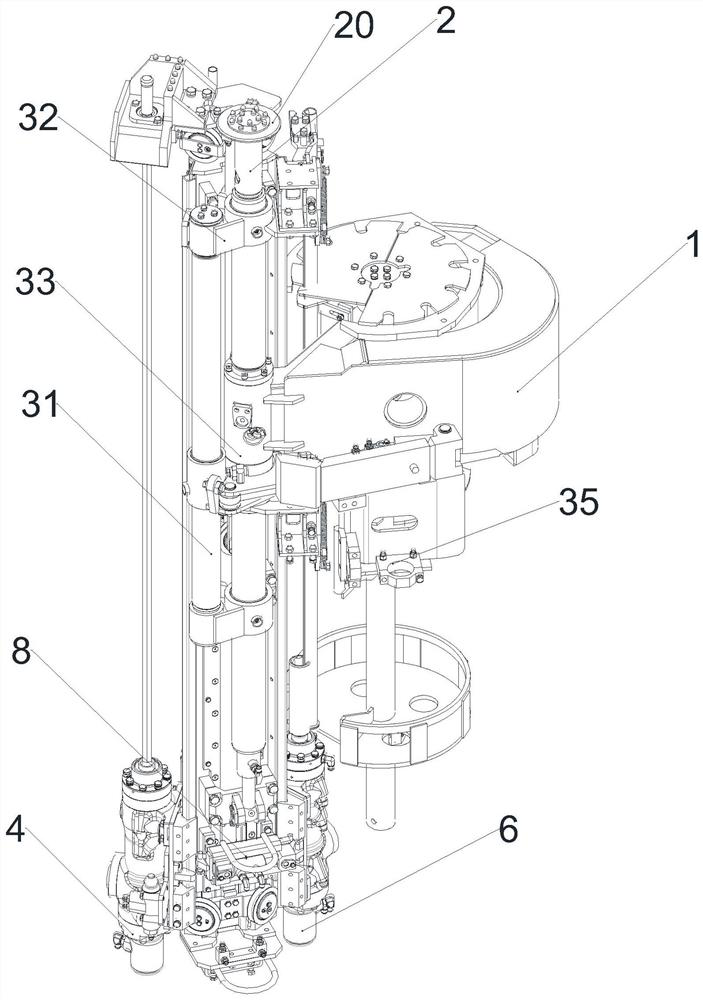

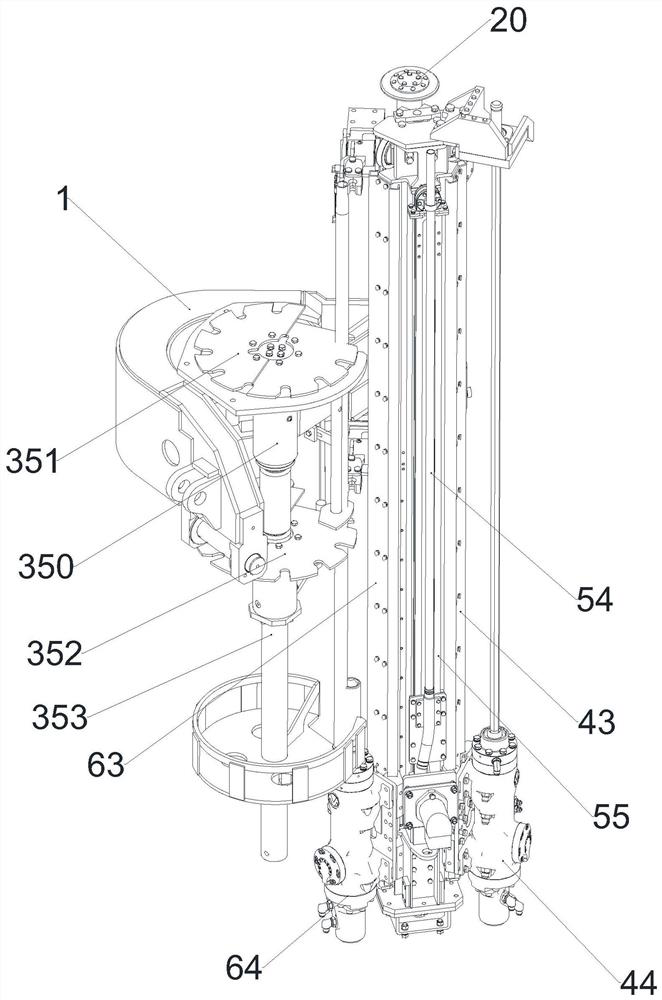

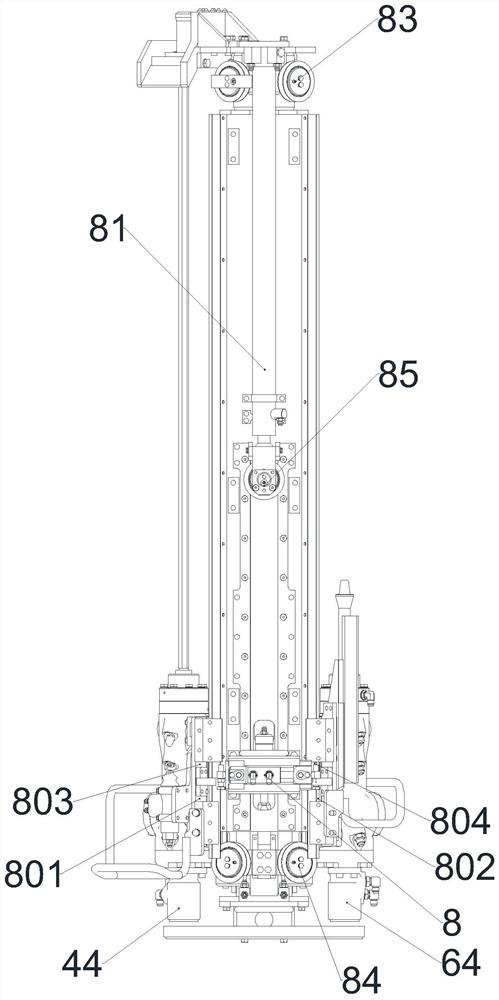

[0051] A hydraulic rock bolter, comprising an engineering chassis, a working arm, such as Figure 1-3 The three-station propulsion beam, electrical device, hydraulic device and cab are shown; among them, the engineering chassis is used to provide support for the whole vehicle to ensure the rigidity and strength of the whole vehicle, and the front lateral telescopic form of the legs of the engineering chassis can ensure The stability of the whole vehicle, the electrical device and hydraulic device are used to ensure the normal operation of the three-station propulsion beam and the working arm, and the cab is used to accommodate the driver and the driver manipulates the working arm and the three-station propulsion beam to complete the underground Support work; the three-station propulsion beam is installed on the working arm and adjusted to the vertical state through the working arm;

[0052] In this embodiment, the three-station propelling beam includes a bracket 1 installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com