Efficient energy-saving screw-type air compressor

A high-efficiency, energy-saving, air compressor technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of high energy consumption of screw air compressors, achieve centralized processing, increase service life, and improve compression efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

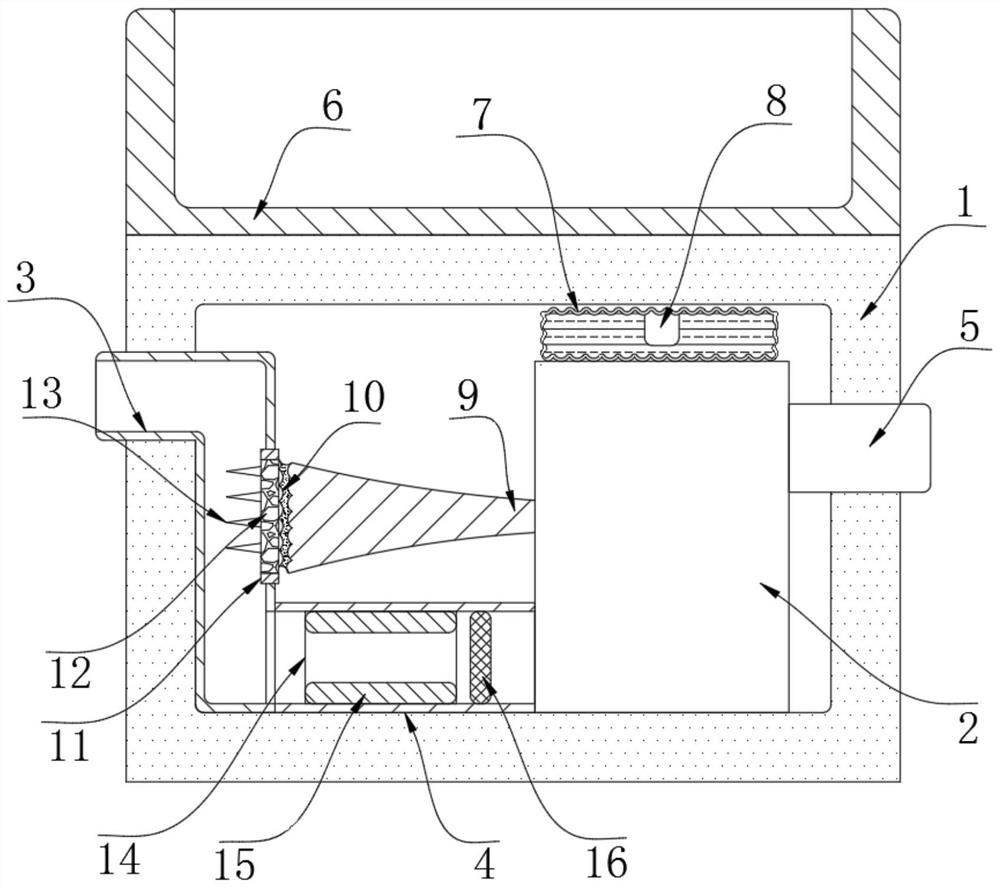

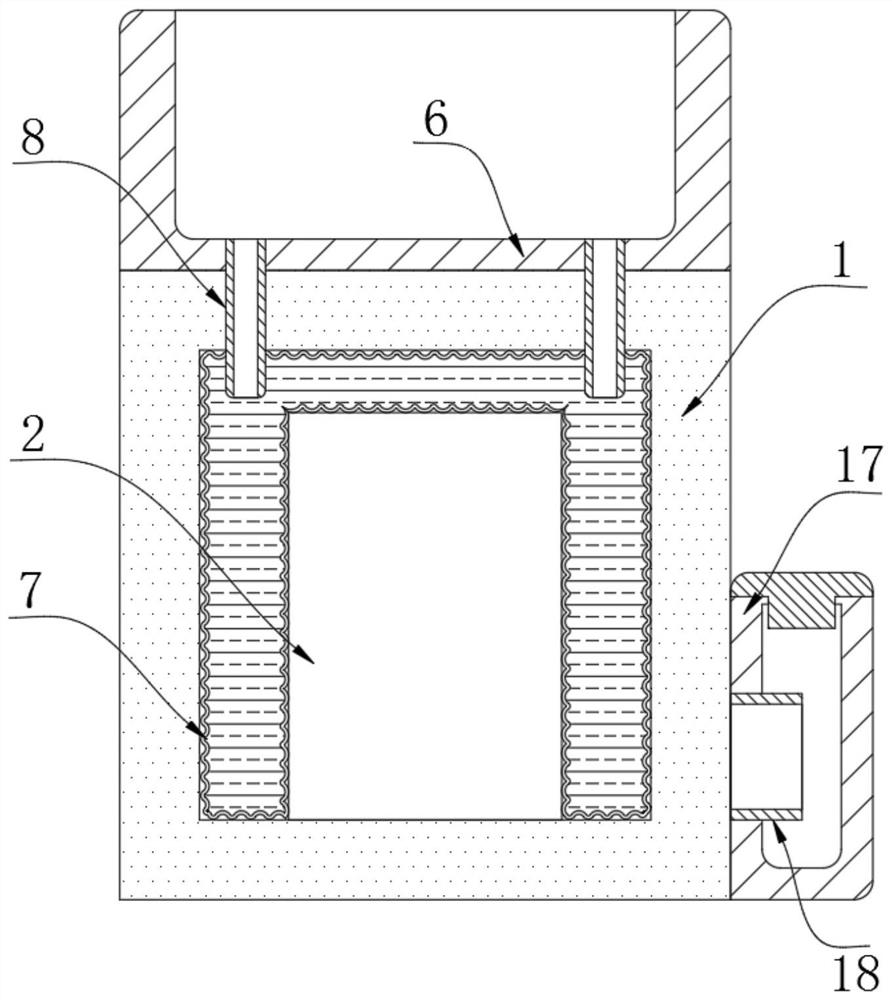

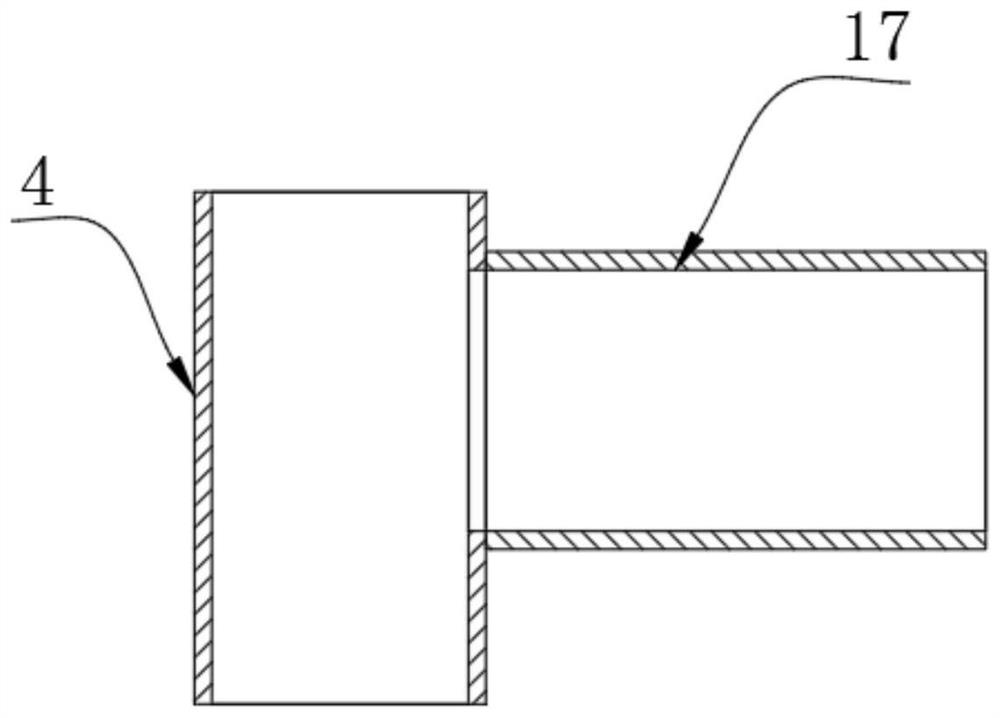

[0019] refer to Figure 1-3 , a high-efficiency and energy-saving screw air compressor, including a casing 1 and a compressor 2 installed inside the compressor 2, the side wall of the casing 1 is inserted with an intake pipe 3, and the side wall of the intake pipe 3 is fixed with a dust removal pipe 4, The dust removal pipe 4 is communicated with the air inlet of the compressor 2, the side wall of the casing 1 is inserted with an exhaust pipe 5 that communicates with the air outlet of the compressor 2, the upper end of the casing 1 is fixed with a cooling box 6, and the side wall of the compressor 2 A fitting tube 7 is fixed, and a plurality of AC tubes 8 communicated with the interior of the fitting tube 7 are inserted through the bottom of the cooling box 6 . The inner wall of the dust removal pipe 4 is provided with a dust discharge mechanism.

[0020] The discharge mechanism includes an insulating ring 11 that penetrates through and is fixed to the side wall of the air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com