Full-section tunnel excavation seepage-stress coupling model test device and method

A technology of tunnel excavation and coupling model, which is used in measuring devices, using stable tension/pressure to test material strength, soil material testing, etc., which can solve the process that cannot consider the seepage-stress coupling mechanism and is difficult to simulate the gradual release of stress. and other problems, to achieve the effect of non-contact measurement of full-field strain and displacement with high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0041] Embodiments of the present invention provide a full-section tunnel excavation seepage-stress coupling model test device and method, which are used in saturated low-permeability formations.

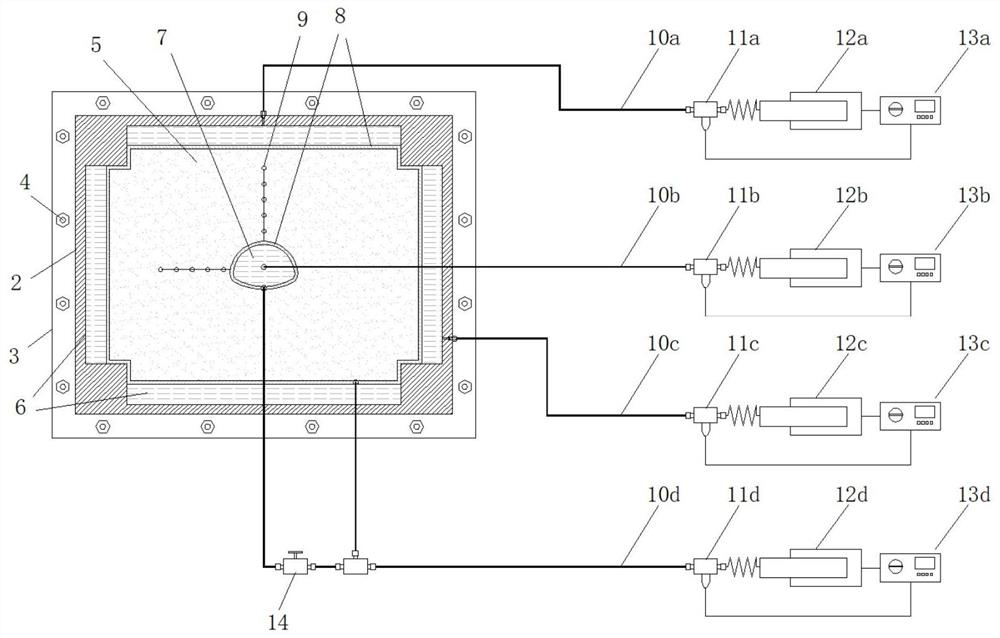

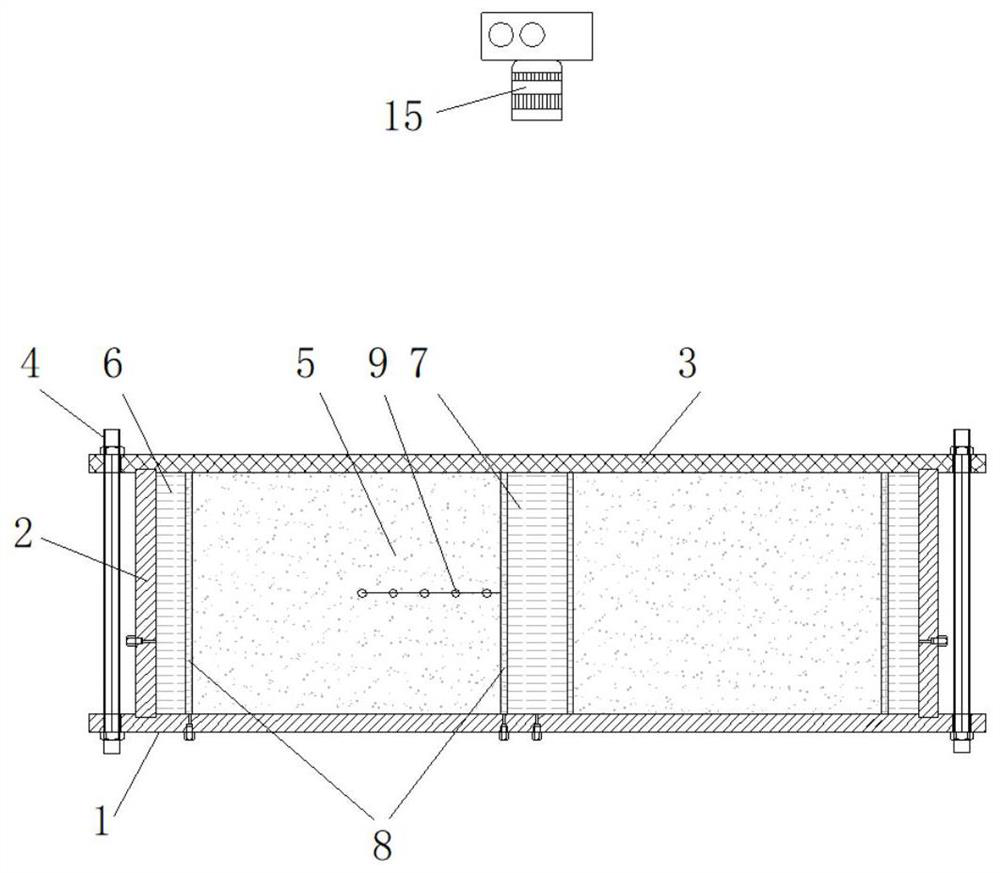

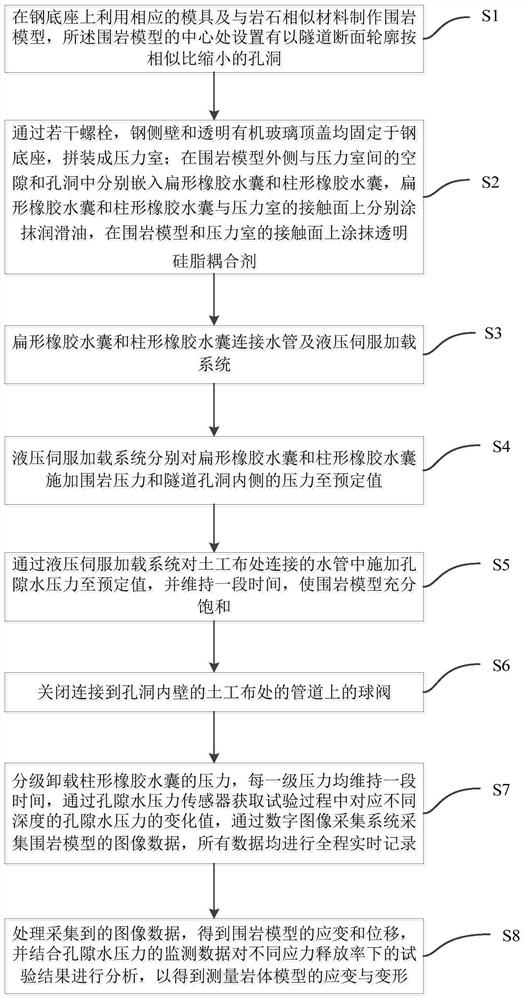

[0042] Please refer to Figure 1-2 , figure 1 It is a structural top view of a full-section tunnel excavation seepage-stress coupling model test device in an embodiment of the present invention, figure 2 It is a side view sectional view of a full-section tunnel excavation seepage-stress coupling model test device in an embodiment of the present invention, specifically including: a pressure chamber, a surrounding rock model 5, a flat rubber water bladder 6, and a cylindrical rubber water bladder 7 , geotextile 8, pore water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com