Die-cutting product detection method and software

A detection method and product technology, which is applied in the direction of measuring devices, computer components, character and pattern recognition, etc., can solve the problems that human eyes cannot perform accurate size measurement, cannot meet the detection and measurement requirements, and the efficiency of manual detection is low, so as to achieve accurate High efficiency, cost saving, and the effect of preventing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

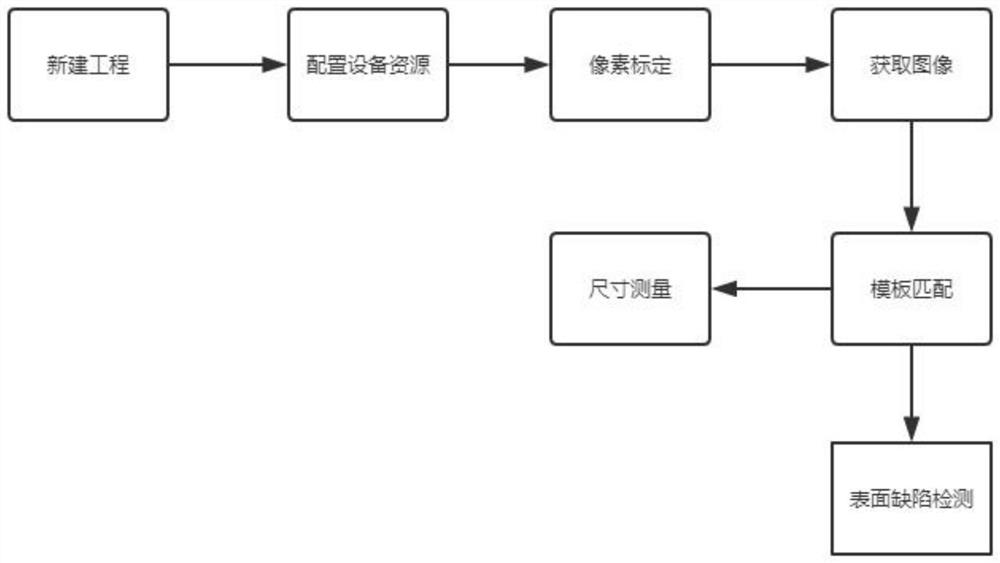

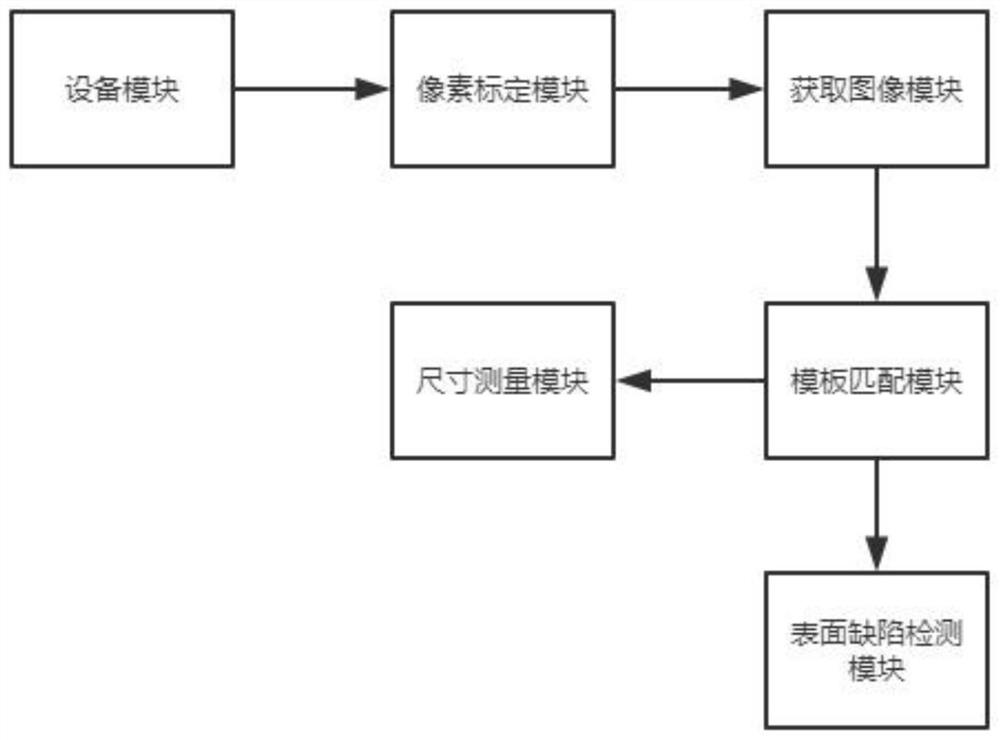

[0030] refer to figure 1 Shown, a kind of die-cut product detection method in a preferred embodiment of the present invention is characterized in that, comprises the following steps:

[0031] S1. Create a new project, select the project storage path and specify the project name;

[0032] S2. Configure device resources, provide a shooting camera, and set the exposure, gain and Gamma of the camera and the input and output signal parameters of the IO card in the device module of the camera;

[0033] S3, pixel calibration, pixel calibration is performed in the pixel calibration module through a line-to-line tool or a circle tool, and the actual length corresponding to each p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com