Cloth surface defect online monitoring device and monitoring method thereof

A surface defect and monitoring device technology, which is applied in measuring devices, optical testing of defects/defects, and material analysis through optical means, and can solve problems such as drastic changes in lighting, missed inspections, and affecting cloth defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

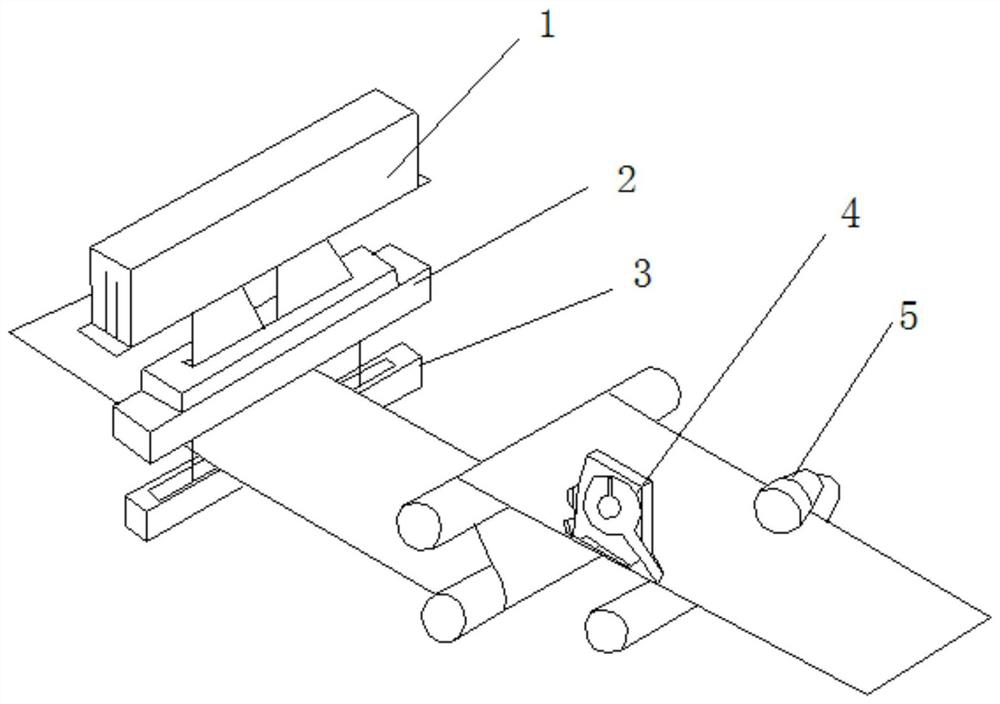

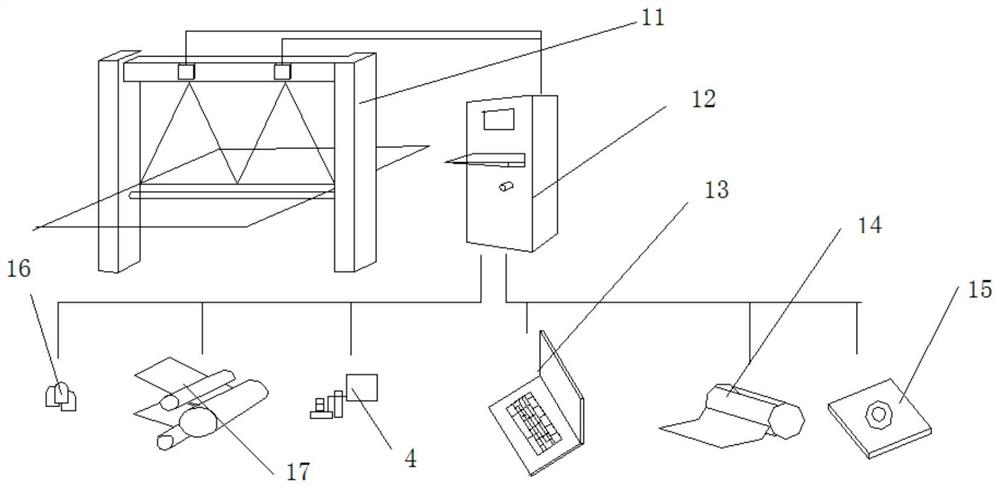

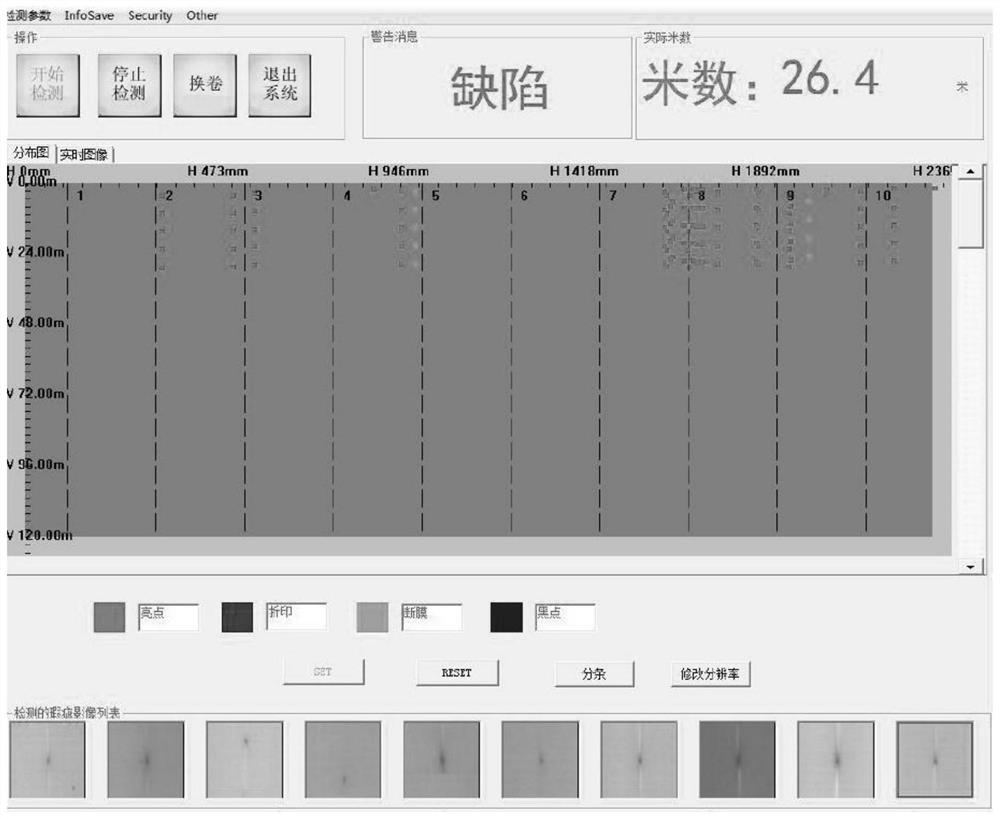

[0034] An online monitoring device for cloth surface defects (see attached Figures 1 to 4 ), configured on the cloth production line through the installation bracket 11, including a computer for identification, a labeling machine 4 for labeling defects, an encoder 5, a positive light source 2, a backlight source 3 and a recognition camera 1, and the positive light source is configured in Above the backlight source, the front light source includes a back-shaped light source platform with a rectangular hole in the center, the light sources of the light source platform are evenly arranged on both sides of the long side of the rectangular hole, and the recognition camera is arranged at the center of the rectangular hole Above, the recognition camera, front light source and backlight form a straight line perpendicular to the cloth, the output end of the recognition camera is electrically connected to the recognition computer, the labeling machine is located behind the recognition c...

Embodiment 2

[0042] This embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, the identification computer performs big data collection through a big data acquisition station before performing online monitoring work, and the big data acquisition station includes flawed Cloth, reciprocating conveyor belt 23, front adjustable light source 21, back adjustable light source 22, shaking device 25 and encoder, the encoder is installed on the reciprocating conveyor belt to code and read the transmission distance of the reciprocating conveyor belt, and the recognition camera is installed On the reciprocating conveyor belt, the cloth with defects is installed on the reciprocating conveyor belt, the front adjustable light source, the rear adjustable light source and the recognition camera form a straight line perpendicular to the cloth with defects, and the front The control ends of the adjustable light source and the back adjustable light source are connected to...

Embodiment 3

[0044] A method for on-line monitoring of cloth surface blemishes, suitable for the on-line monitoring device for cloth surface blemishes as described in Example 2,

[0045]Step 1: The cloth production line is running, the light source of the light source table is started, the encoder detects the current transmission speed of the cloth production line, and the identification computer determines the current cloth position according to the encoder data;

[0046] Step 2: The recognition camera monitors the image of the cloth within the range of the current light source and transmits it to the computer for recognition, and the computer for recognition receives the image information of the cloth;

[0047] Step 3: The computer for identification performs identification according to the predetermined parameters. The identification is divided into normal and defective states. If there is a defect, the computer for identification will send a control command to the labeling machine, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com