Wind speed sensor and preparation method thereof

A technology of wind speed sensor and temperature sensor, which is applied in the direction of instrumentation, acceleration measurement, multi-dimensional acceleration measurement, etc., can solve the problem of low sensitivity, achieve the effect of improving sensitivity, improving measurement accuracy, and reducing heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

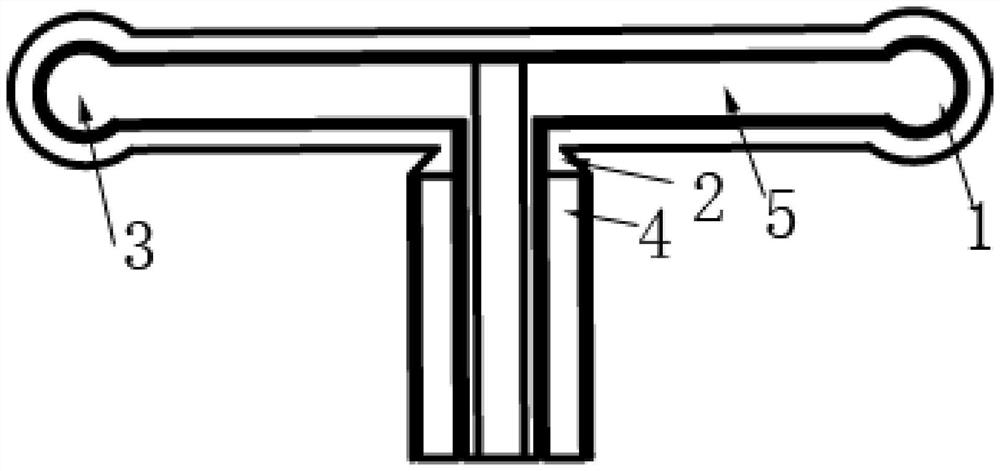

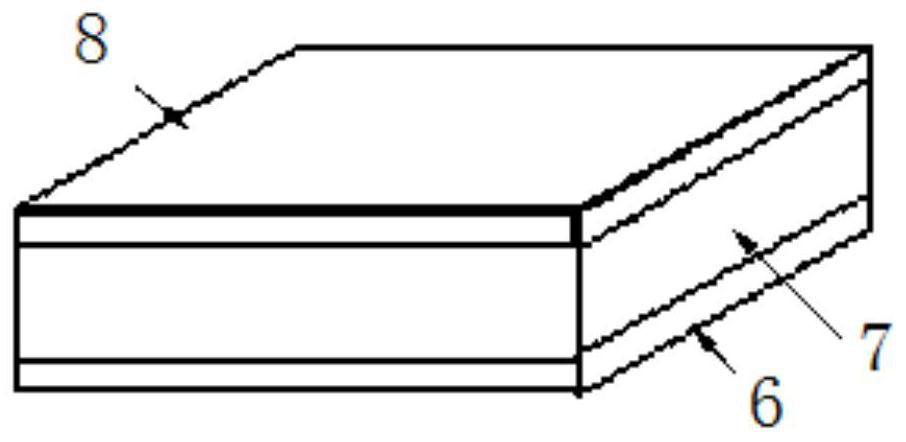

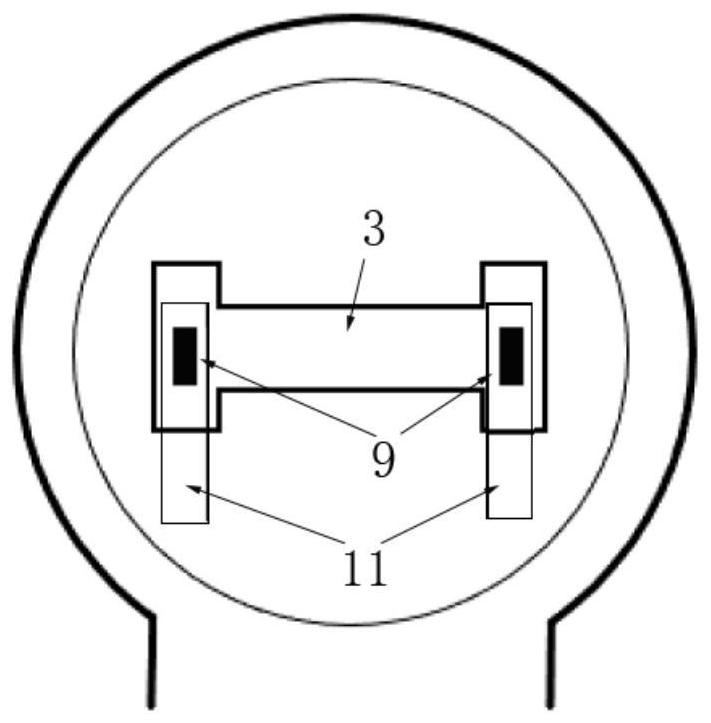

[0040] A wind speed sensor, comprising a speed measuring unit located in a confined space, the structure of the speed measuring element is as follows figure 1 As shown, the speed measurement unit includes a T-shaped heater 1 and a temperature measurement sensor 2 located in a closed space, and the speed measurement unit is placed in a closed cavity composed of a silicon substrate and a top packaging cover (not shown in the figure). The T-shaped heater 1 is a T-shaped structure. Two heating resistors are respectively arranged at both ends of the transverse part of the T-shaped structure. The two heating resistors are placed in the center of the two ends of the airtight cavity and connected by a cantilever beam 5, such as figure 1 The position 3 of the heating resistor in the middle is shown, and the specific shape of the heating resistor is not shown; the temperature measuring sensor 2 is arranged around the outside of the T-shaped structure, and two measuring sensors are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com