Zinc flotation dosing prediction control method based on texture degree optimization

A predictive control and dosing technology, applied in flotation, image data processing, solid separation, etc., can solve the problems of uncombined foam state of multiple flotation cells, production status cannot be fully monitored and adjustment is not timely, to achieve The effect of reasonable and efficient drug dosage prediction control and long process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the technical solutions and advantages of the present invention in more detail, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

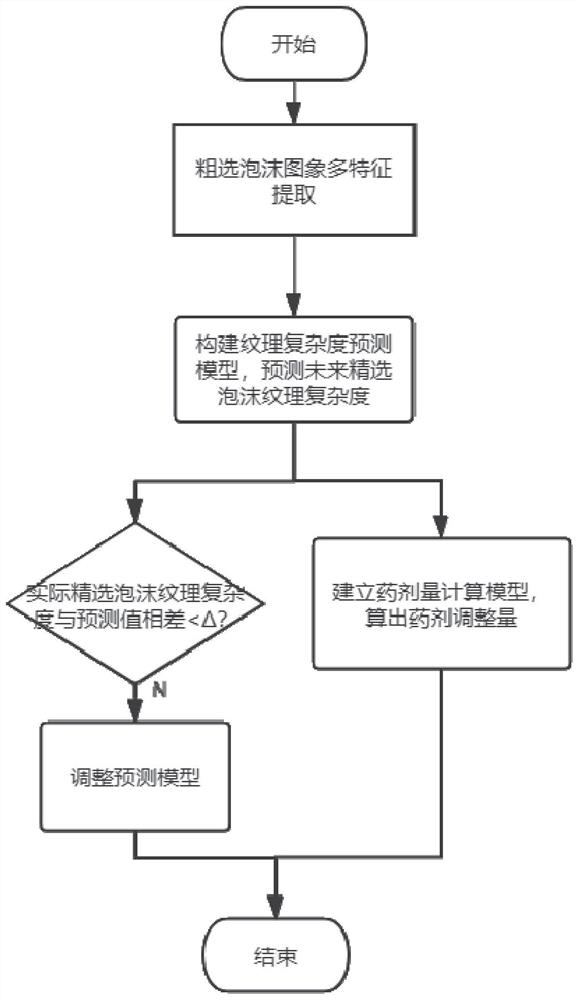

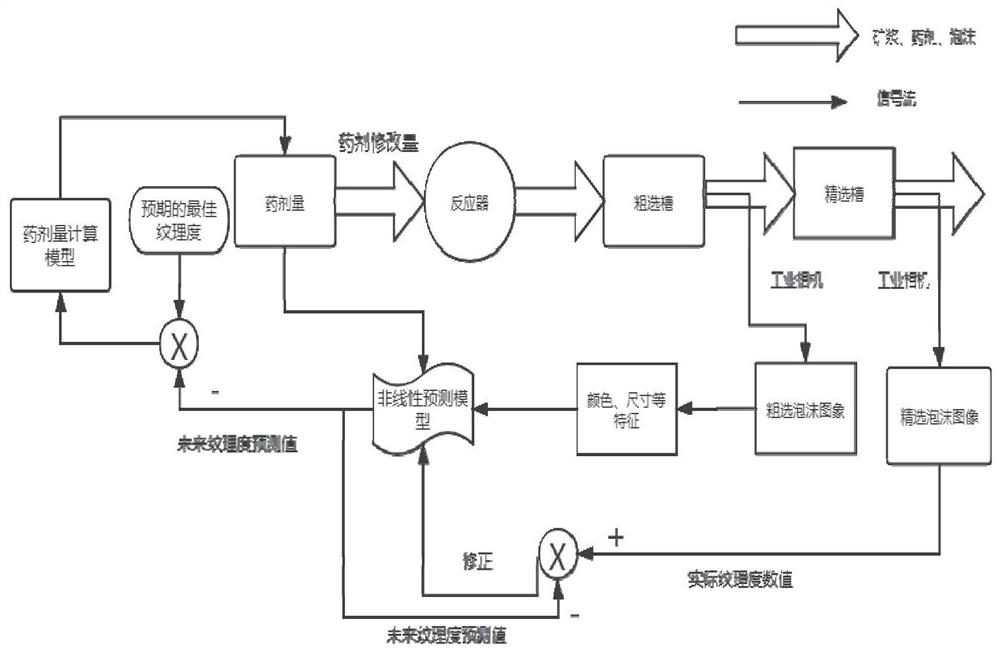

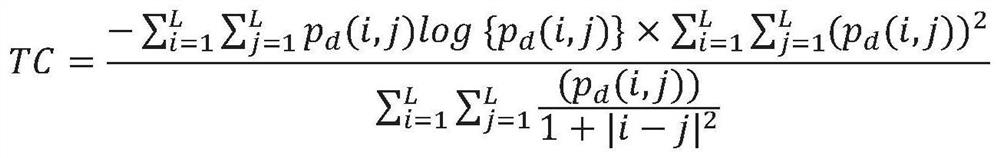

[0035] S1. Extract the froth image features in the zinc flotation roughing tank, including the entropy value, energy, negative moment, froth size and froth color of the flotation froth image: by extracting the features of N zinc rough froth images, take The spatial gray level co-occurrence matrix method, that is, the SGLCM method, extracts the entropy value, energy, and inverse moment of the foam image to obtain specific data sets Er=[E1, E2, E3, E4...En], A r =[A1, A2, A3, A4, . . . An], C r =[C1, C2, C3, C4,...Cn], using the classic watershed algorithm to segment and extract foam size feature data S=[S1, S2, S3, S4...Sn], foam color features via HSV color The channel is calculated to obtain the data Co=[Co1, CO2, CO3, CO4...Con], and the fiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com