Double-backboard structure and ATR case thereof

A double-backplane and chassis technology, applied in the direction of support structure installation, electrical equipment construction parts, electrical components, etc., can solve the problems of difficult disassembly and maintenance, high cost, high failure rate of flexible fixation, etc., to ensure signal integrity and simplify Production process, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

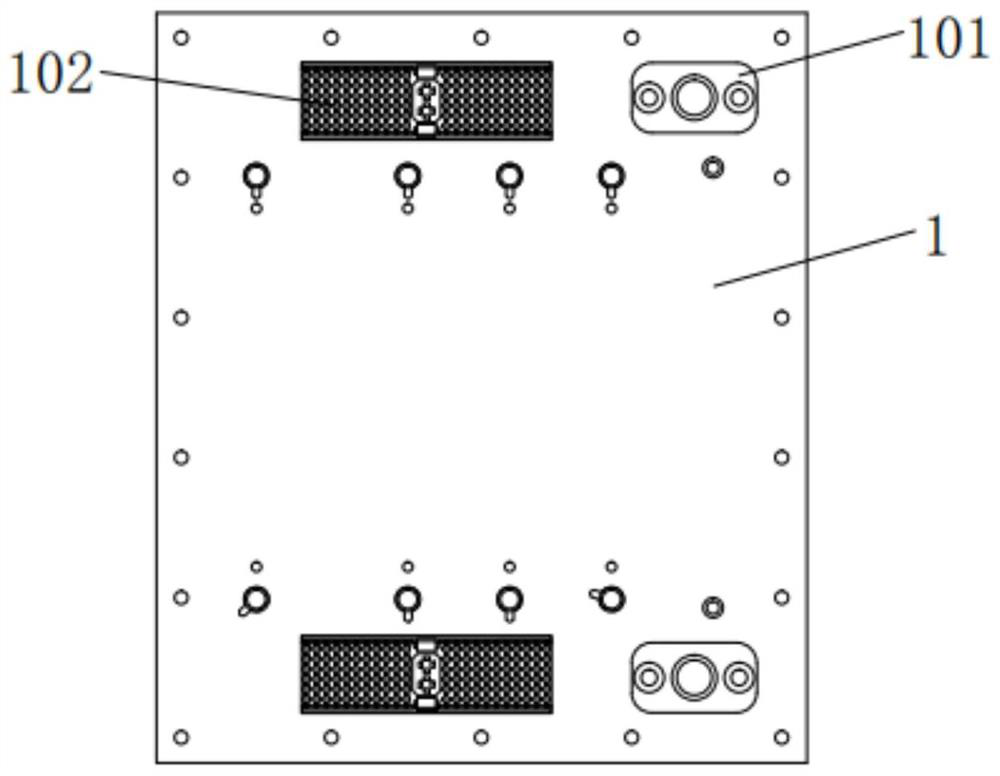

[0037] A double backplane structure, including A backplane 1 and B backplane 2,

[0038] A sub-board connector 102 is embedded on the A backplane 1, and a positioning pin seat 101 is fixedly installed on one side of the A backplane 1;

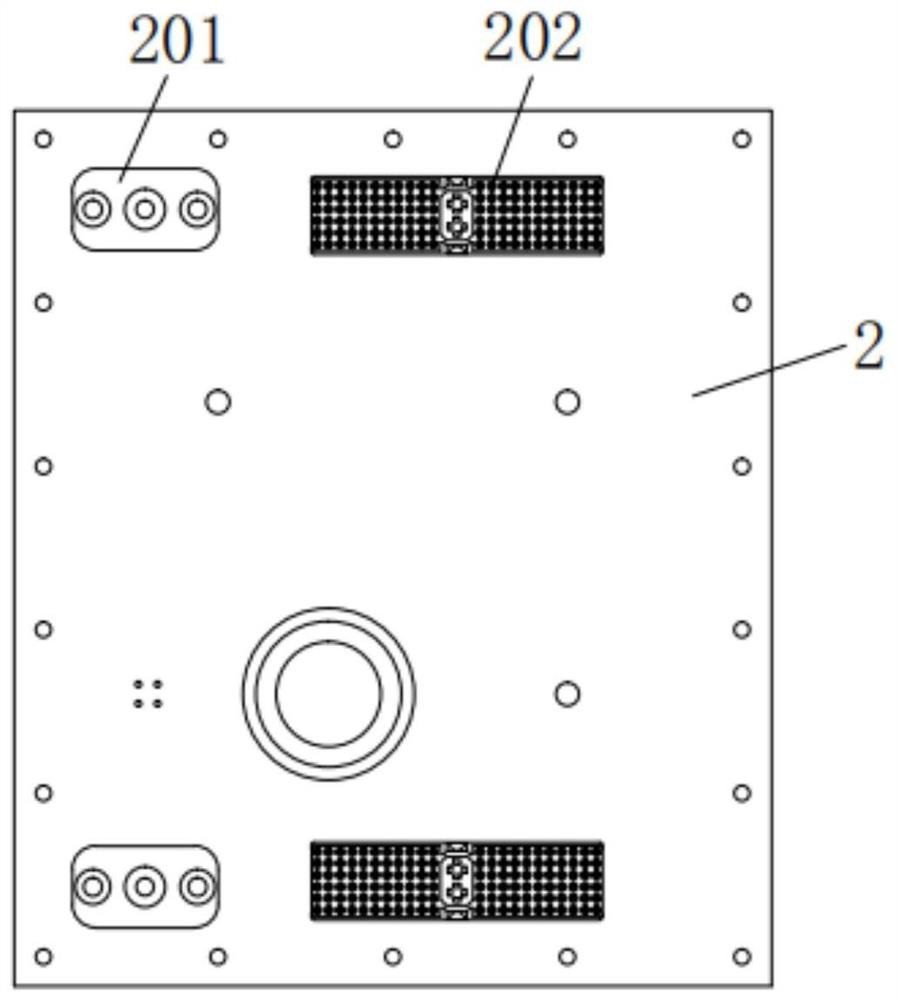

[0039] A motherboard card connector 202 is embedded on the B backplane 2, and a positioning pin 201 is fixedly installed on one side of the B backplane 2, and the positioning pin 201 is plugged into the positioning pin seat 101. Inside, the B backplane 2 is connected to the A backplane 1 through the alignment pin 201 and the alignment pin seat 101, and the B backplane 2 is parallel to the A backplane 1, the motherboard card connector 202 is plugged and connected to the daughter card connector 102, and the motherboard card connector 202 is electrically connected to the daughter card connector 102.

[0040] Wherein, the B backplane 2 is also installed with a fixed spacer 204 through screws 205, and the inner interference fit of the fixed spacer ...

example 1

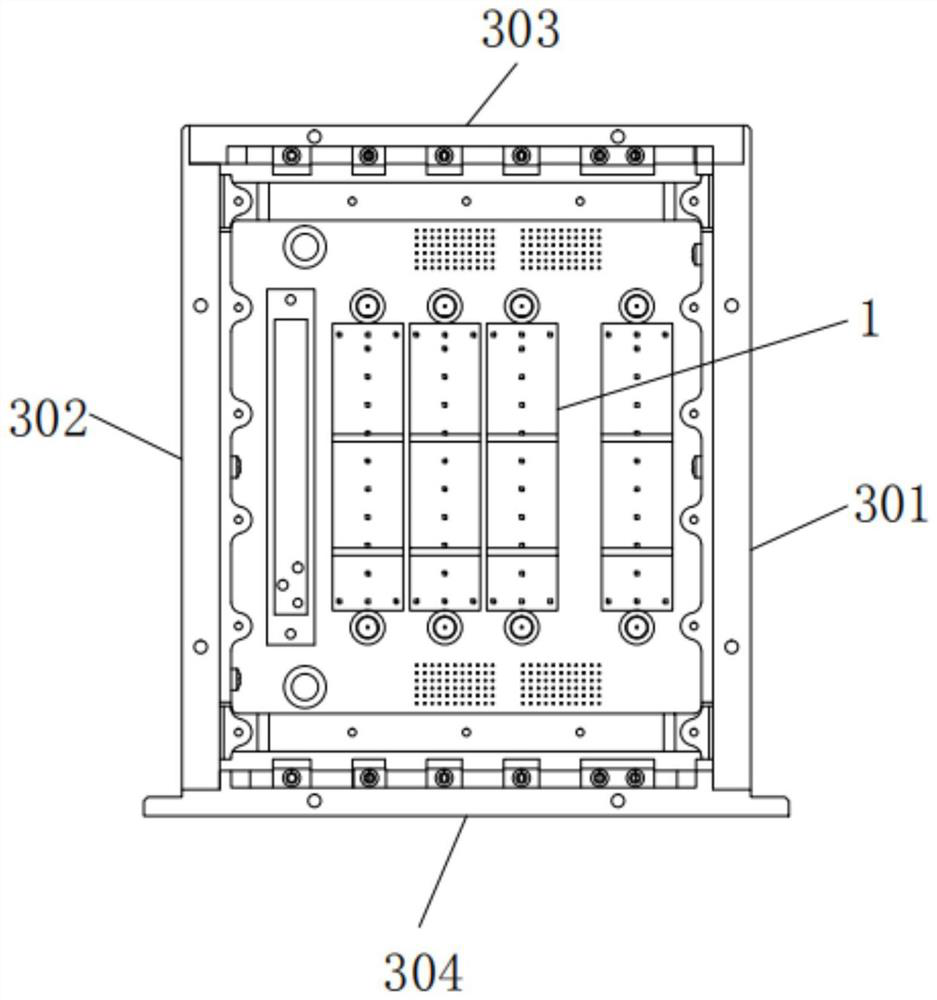

[0057] Such as image 3 and 4 as shown, image 3 For the A backplane, place 5 pieces of electrical connectors (the number of electrical connectors changes with the number of sub-boards, and the limit size of the chassis changes accordingly) and positioning pins, etc., to realize the plug-in connection function with the sub-boards inside the chassis. Use the backplane fixing structure to tightly connect the A backplane and the overall structure of the chassis through screws, and all the fixed adapters and the A backplane can be disassembled and replaced. Figure 4 For the B backplane, place 5 pieces of aviation electrical connectors (the number of aviation electrical connectors is determined according to the use requirements), and the electrical connectors are directly welded to the backplane to realize power supply and signal transmission functions. The size of the A backplane and the B backplane is the same, the height of the backplane is the same as the height of the sub-b...

example 2

[0059] Such as Figure 5-8 As shown, the aviation electrical connector is welded as a whole with the B backplane through a special fixing pad, and then fixed to the back structure of the chassis by screws. Figure 8 It is designed for a special fixed pad, and the size of the marked place needs to be designed with a negative tolerance (0-0.3), which is convenient for the interference fit and fixation of the aviation electrical connector and the special fixed pad. By adopting this design scheme, both in-line welding of aviation electrical connectors and detachable structural installation can be taken into account, and the operation is simple and the cost is low.

[0060] During the production and assembly process, the assembly is completed according to the following process to ensure the welding accuracy of the aviation electrical connector:

[0061] In the first step, the aeronautical electrical connector and the special fixed pad are interference-fit assembled;

[0062] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com