Convertible top element and convertible top or a convertible vehicle and convertible vehicle

A convertible car and component technology, applied in the field of convertible cars, can solve the problems of inability to properly absorb noise, high wind noise of vehicles, etc., and achieve the best noise comfort, high sound insulation performance, and low self-weight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

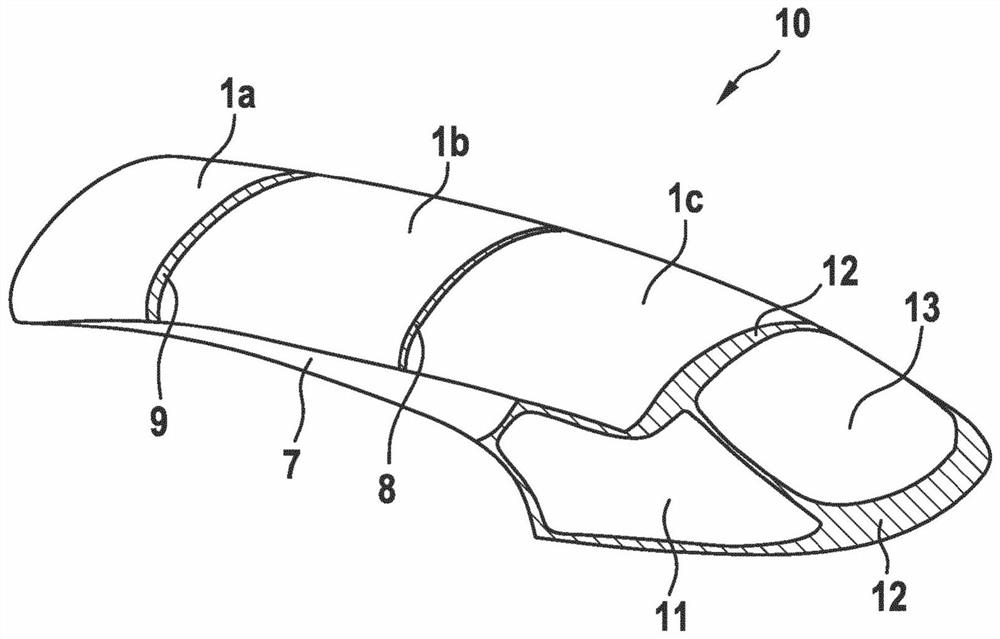

[0055] Only the first roof element according to the invention and the elements of the roof which are relevant to the invention are shown in the figures. All remaining elements are omitted for clarity. Furthermore, the same reference numerals identify the same elements.

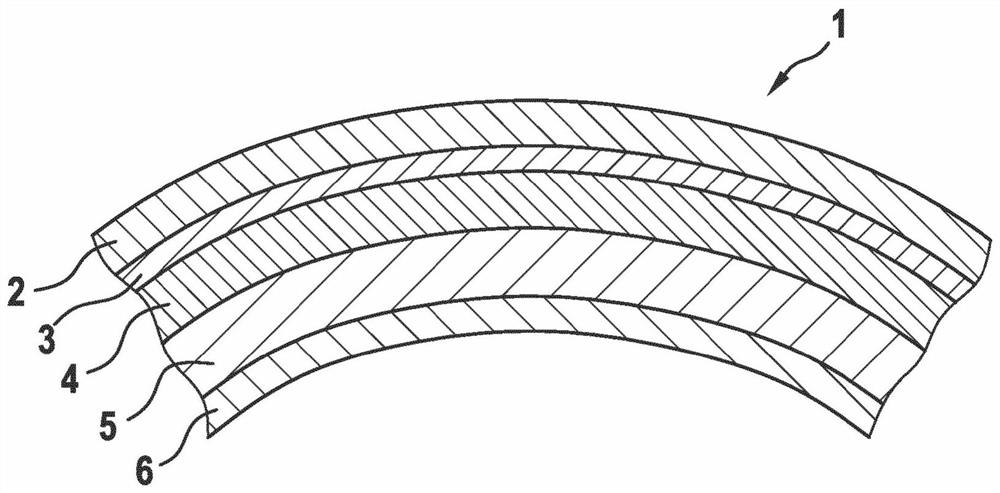

[0056] figure 1 The first roof element 1 for a convertible vehicle and in particular the layer construction or layer arrangement of the first roof element is shown in detail in a sectional view.

[0057] The first roof element 1 has an outer roof layer 2 which is designed to be waterproof and has a thickness of 1100 g / m 2 up to 1300g / m 2 , especially 1450g / m 2 Weight per unit area and layer thickness from 1mm to 1.5mm. The outer roof layer 2 is in particular a laminate comprising a butyl rubber layer surrounded on both sides by two acrylate layers. The outer roof layer 2 forms the outermost layer of the first roof element which, when installed in a roof for a convertible, comes into contact with the envi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com