Turnover mixer with powder block cutting and crushing function

A mixer and functional technology, applied in the direction of mixers, jitter/oscillation/vibration mixers, cleaning methods using tools, etc., can solve the problems of lower output quality, low mixing efficiency, heat generation of motors, etc., and achieve extended use Long life, improved mixing effect, fine powder effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

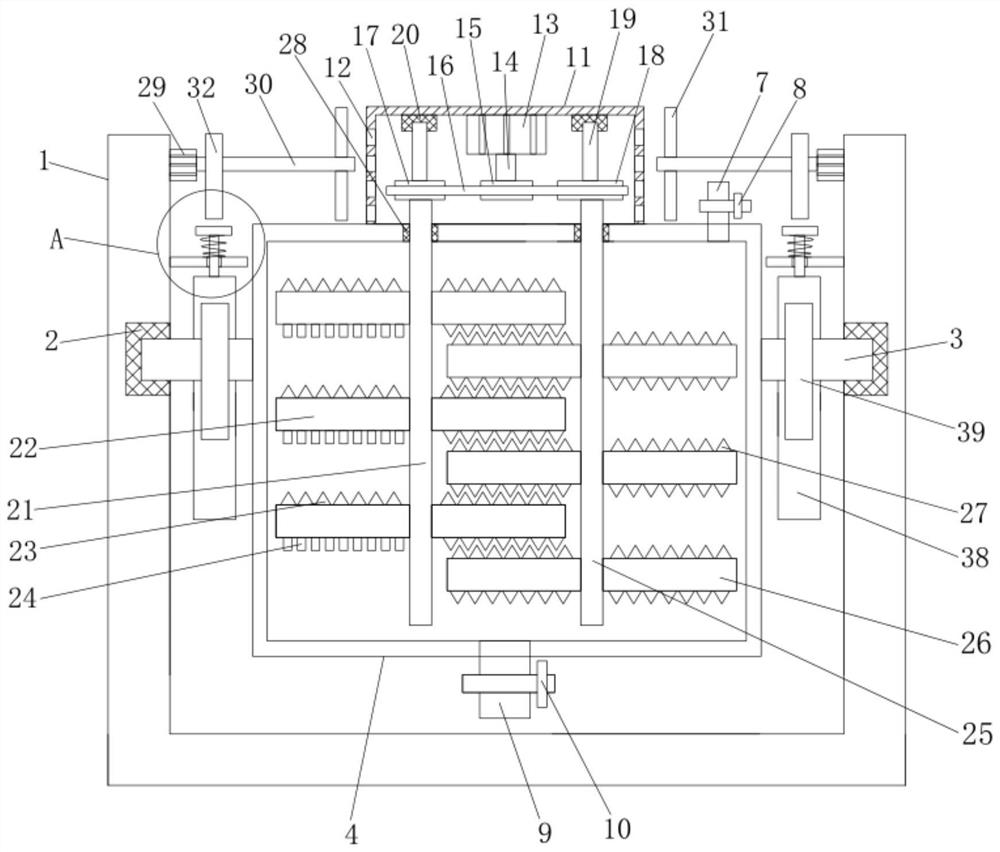

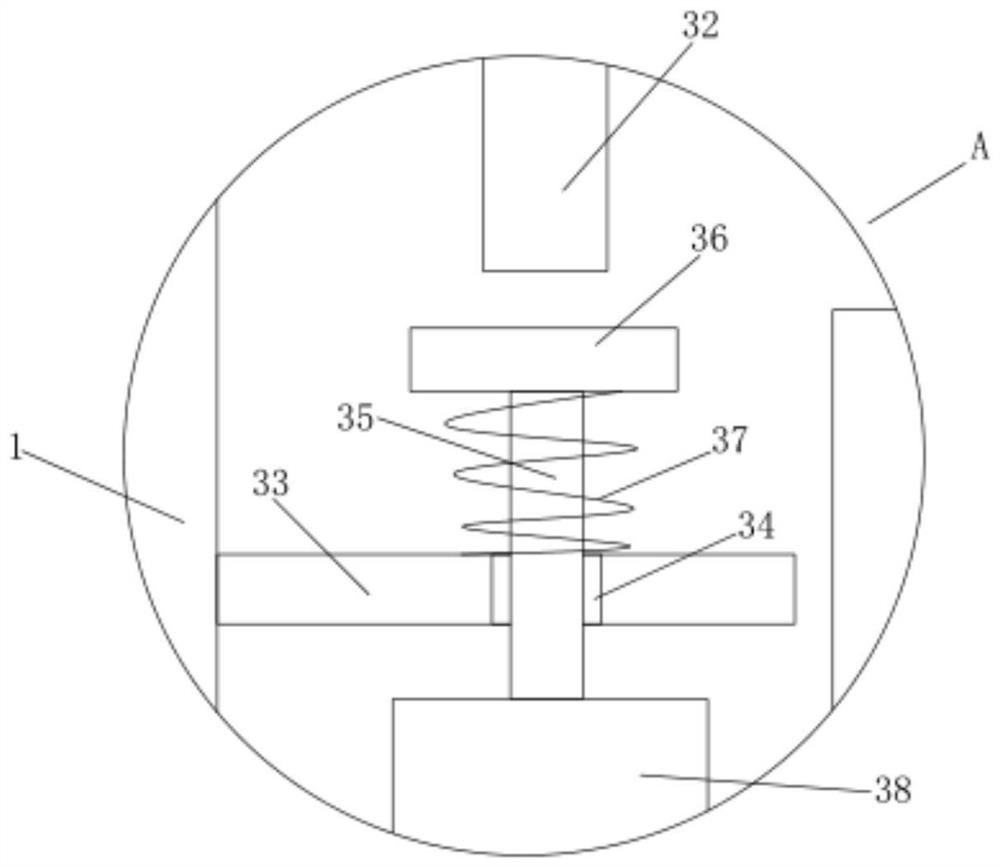

[0027]Embodiment: first close the discharge valve 10, open the feed valve 8, add the powder material to be processed from the feed pipe 7 to the inner cavity of the mixing box housing 4, then start the drive motor 13 and the turning motor 29, drive The motor 13 drives the driving wheel 15 to rotate through the transmission shaft 14, and the driving wheel 15 drives the first driving wheel 17 and the second driving wheel 18 to rotate through the belt. When rotating, the first driving wheel 17 drives the first stirring blade through the first stirring rod 21 22 rotation, the second transmission wheel 18 drives the second stirring blade 26 to rotate through the second stirring rod 25. At the same time, because the diameters of the first transmission wheel 17 and the second transmission wheel 18 are different, the rotation of the two in the same time period The number of circles will be different, which results in the cross position of the first stirring blade 22 and the second stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com