Flow-stabilizing anti-blocking screen hydraulic swirler

A hydrocyclone and screen technology, which is applied to cyclone devices, devices whose axial directions of cyclones can be reversed, chemical instruments and methods, etc. Reducing the effects of poor grading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

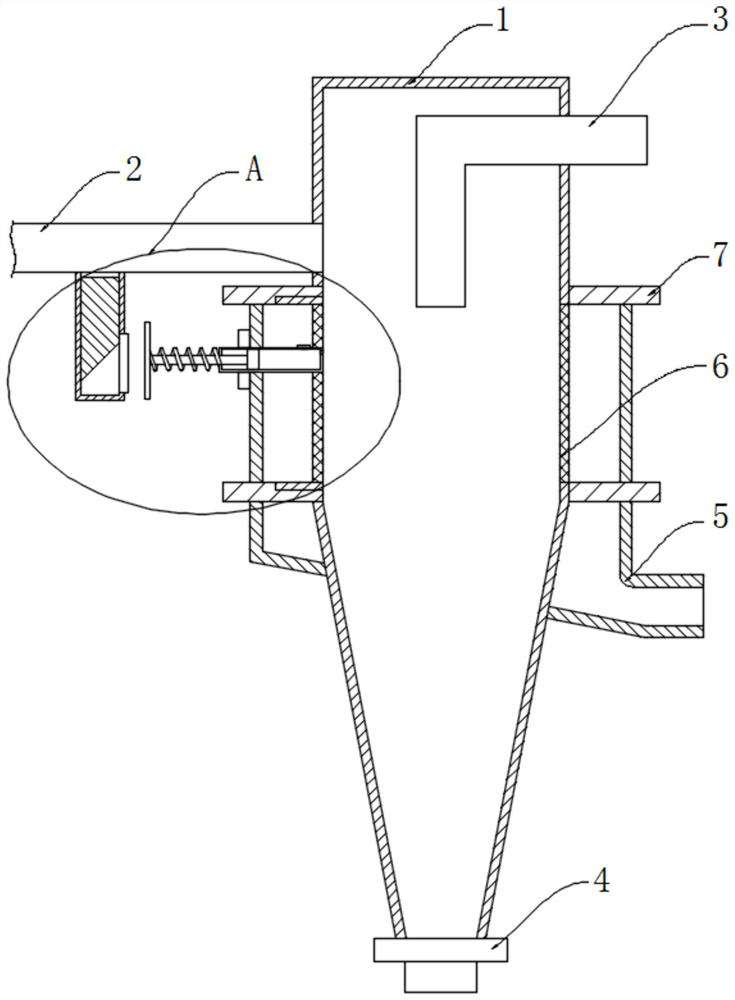

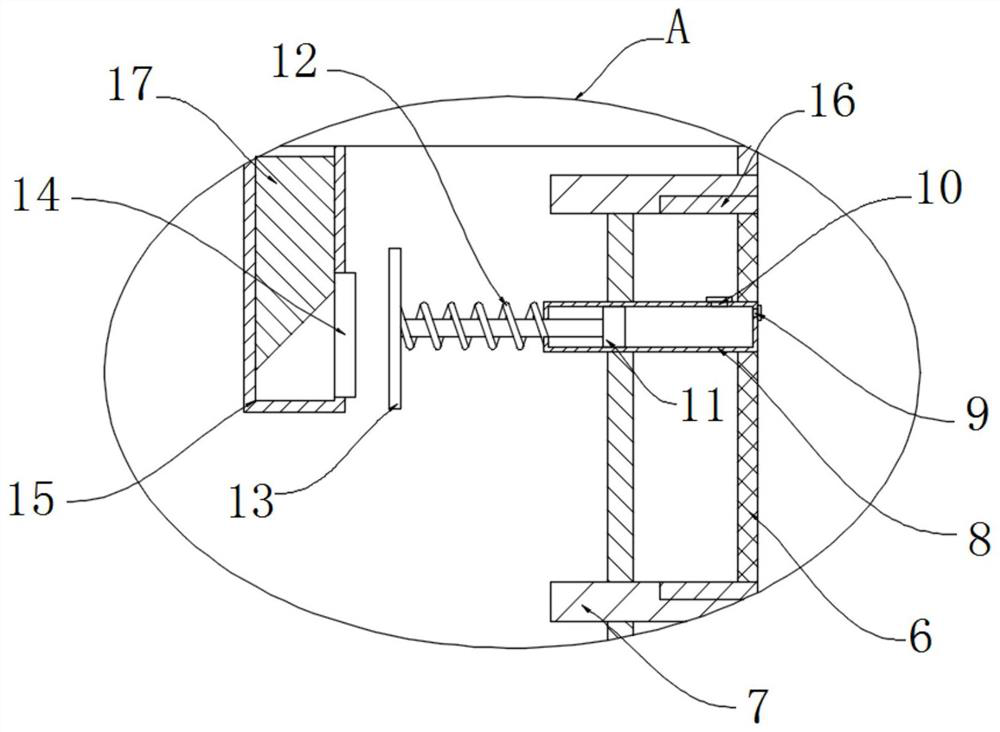

[0021] refer to Figure 1-3 , a screen hydrocyclone with stable flow and anti-blocking, including a body 1, a feed pipe 2 and an overflow pipe 3, the bottom of the body 1 is set in a conical structure and a discharge port 4 is opened, and the middle part of the body 1 is covered A screening box 5 is connected and fixed, and the screening box 5 communicates with the body 1 and is provided with an annular screen 6. The screening box 5 is fixedly connected with a cylinder 8, and the cylinder 8 is sealed and slidingly connected with a piston 11, and one end of the cylinder 8 is sealed. It runs through the screen 6 and the other end is sealed and runs through the inner wall of the screening box 5. The cylinder 8 is provided with a cross-shaped pressing rod 13 on one side of the screening box 5. The pressing rod 13 is fixedly connected with the piston 11. The outer part of 8 is sleeved with spring 12;

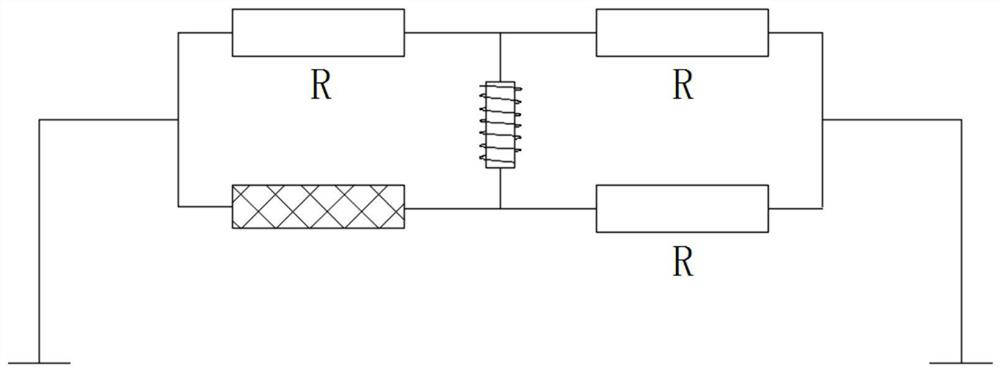

[0022] The part of the cylinder body 8 in the screening box 5 is respectively p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com