Computer numerical control polishing device for precision machining of sapphire

A technology of precision machining and polishing device, applied in the direction of grinding drive device, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of increasing the labor intensity of workers, affecting the quality of polishing, arm fatigue, etc. Quality, convenient operation and use, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

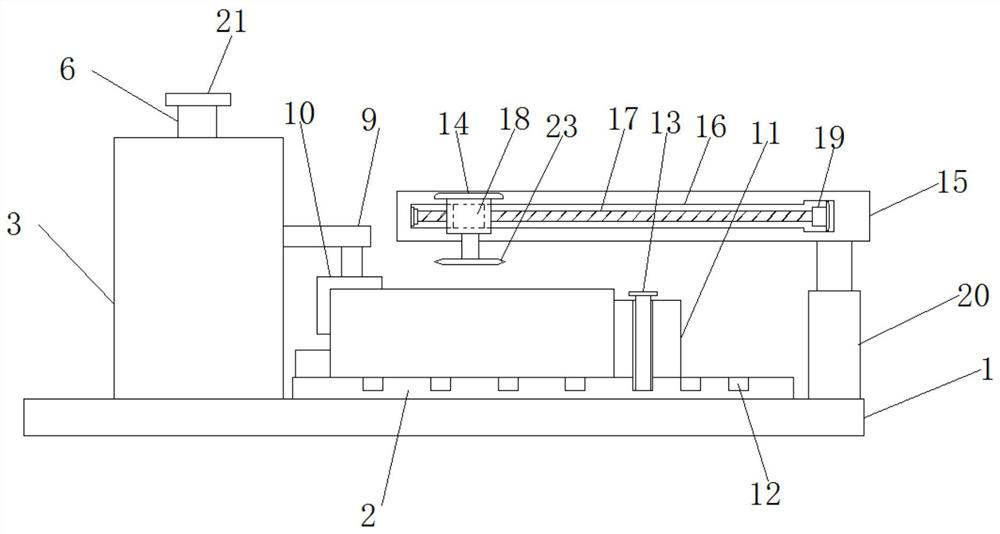

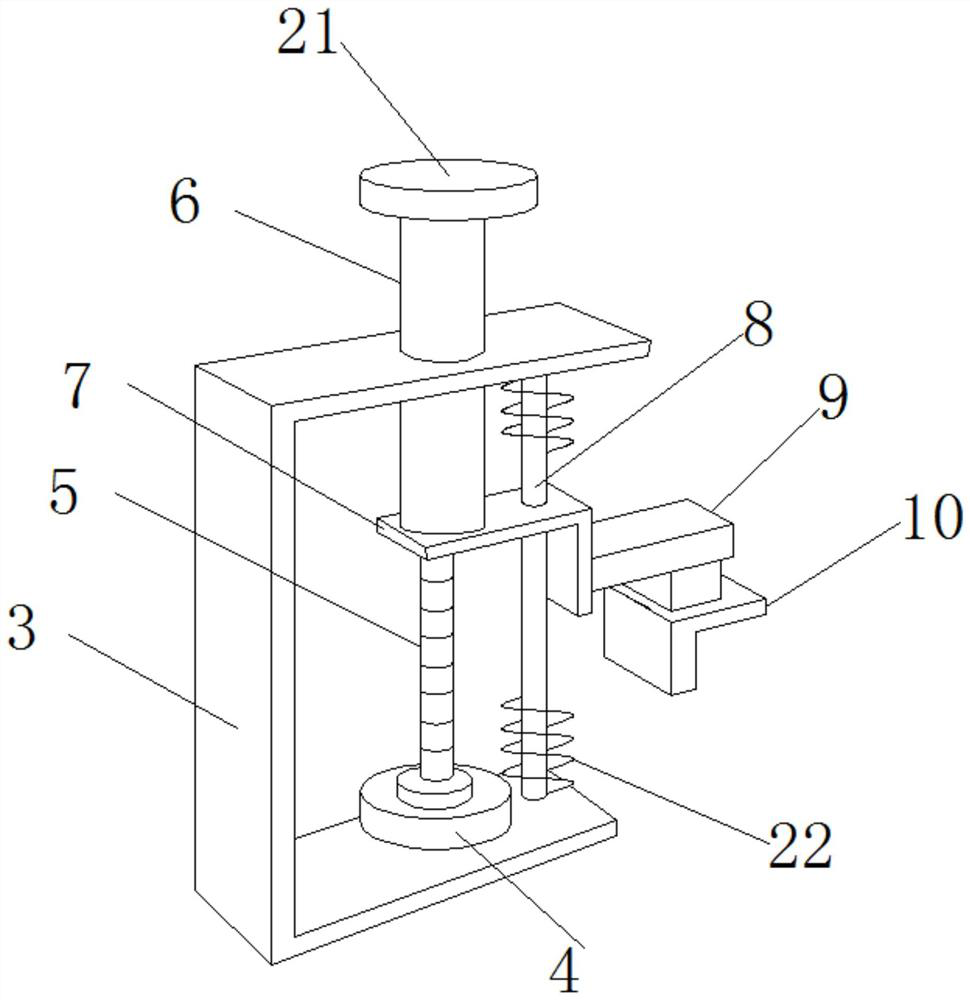

[0023] see Figure 1-2 According to an embodiment of the present invention, a numerically controlled polishing device for sapphire precision machining includes a bottom plate 1, one side of the bottom plate 1 is provided with a placement platform 2, and one side of the placement platform 2 is provided with a limiting device, and the placement A clamping device is provided on the side of the table 2 away from the limiting device, and the clamping device includes a frame body 3, and a first motor 4 is provided inside the frame body 3, and the extension of the first motor 4 The end is provided with a first threaded rod 5, and one end of the first threaded rod 5 away from the first motor 4 is threaded with a threaded barrel 6, and one end of the threaded barrel 6 is fixedly provided with an L-shaped plate 7, the L The end of the template 7 away from the threaded cylinder 6 is penetrated with a slide rod 8, both ends of the slide rod 8 are fixedly connected to the inner wall of the...

Embodiment 2

[0025] see Figure 1-2 , for the supporting sliding device, the supporting sliding device includes a horizontal plate 15, one side of the horizontal plate 15 is provided with a chute 16, the inside of the chute 16 is provided with a second threaded rod 17, and the first Two threaded rods 17 are threaded with a slide block 18, one side of the slide block 18 is fixedly connected with the second motor 14, and one end of the second threaded rod 17 is connected with the output end of the third motor 19 to support the sliding device It can realize that the polishing disk 23 can realize the process of polishing the polishing disk when the sapphire on the placement table 2 is polished; for the chute 16, one end of the chute 16 is located on the horizontal plate 15 There is a placement slot, the third motor 19 is located inside the placement slot, and one end of the horizontal plate 15 is provided with a placement slot, which can realize the process of placing the third motor 19, avoid...

Embodiment 3

[0027] Embodiment one:

[0028] see Figure 1-2 According to an embodiment of the present invention, a numerically controlled polishing device for sapphire precision machining includes a bottom plate 1, one side of the bottom plate 1 is provided with a placement platform 2, and one side of the placement platform 2 is provided with a limiting device, and the placement A clamping device is provided on the side of the table 2 away from the limiting device, and the clamping device includes a frame body 3, and a first motor 4 is provided inside the frame body 3, and the extension of the first motor 4 The end is provided with a first threaded rod 5, and one end of the first threaded rod 5 away from the first motor 4 is threaded with a threaded barrel 6, and one end of the threaded barrel 6 is fixedly provided with an L-shaped plate 7, the L The end of the template 7 away from the threaded cylinder 6 is penetrated with a slide rod 8, both ends of the slide rod 8 are fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com