A metal and non-metal material laser shock glue riveting connection device and method

A non-metallic material, laser shock technology, applied in the field of material glue riveting, can solve the problem of oversize, achieve the effect of light weight, avoid material damage, avoid interaction or electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

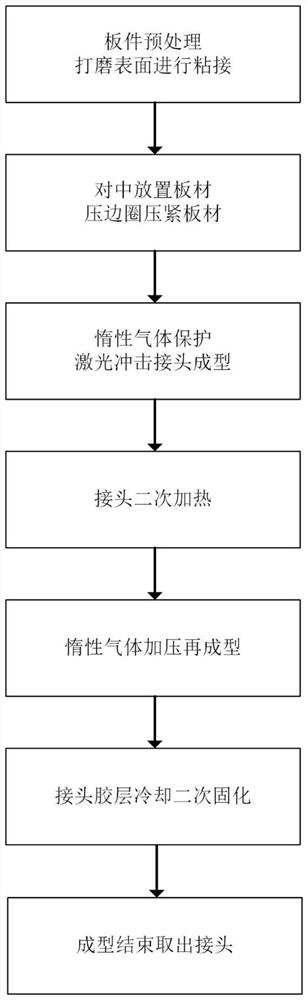

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

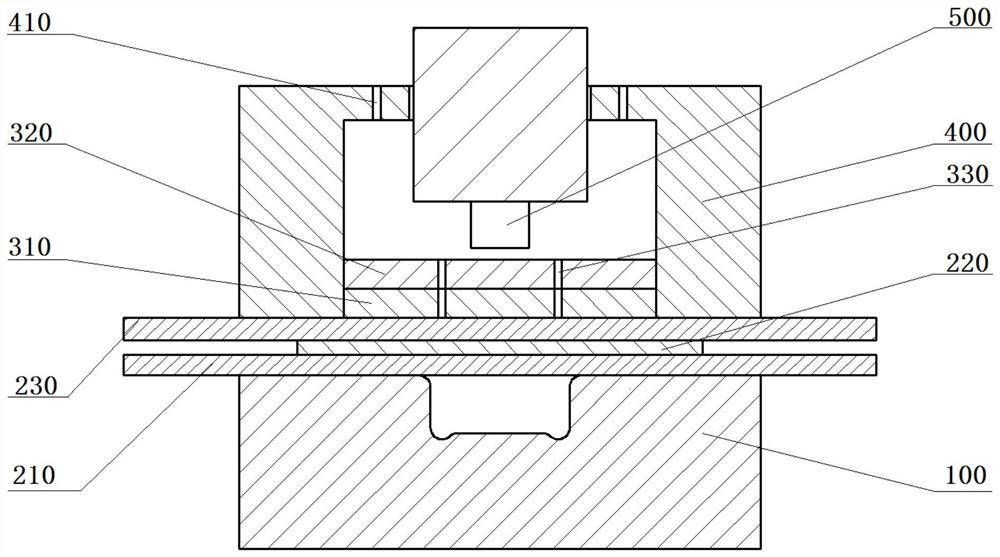

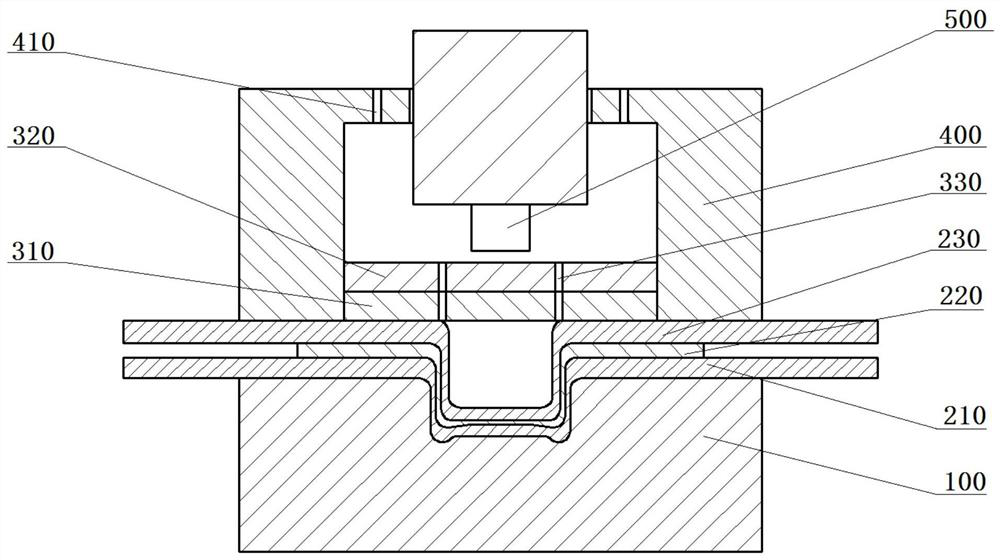

[0054] Such as figure 1 As shown in -4, the present invention provides a laser shock glue riveting connection device for metal and non-metal materials, including: a die 100, a metal sheet layer 210, an adhesive layer 220, a non-metal sheet layer 230, an absorption layer 310, and a constraining layer 320 , the first connection hole 330 , the blank holder 400 , the second connection hole 410 , and the laser generator 500 .

[0055]The die 100 is placed horizontally and has a notch opening upwards. The plate mechanism to be riveted is placed on the die 100 and covers the notch. The blank holder 400 is set on the plate mechanism to be riveted, and the laser shock layer is set on the bezel. Inside 400, the laser generator 500 is supported on the top of the blank holder 400; where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com