Hybrid power mining dump truck driving system

A mining dump truck and drive system technology, applied in the direction of hybrid vehicles, electric braking systems, motor vehicles, etc., can solve the problems of increasing fuel consumption, increasing vehicle operating costs, waste, etc., without adding additional capacity, battery Reasonable capacity matching and the effect of controlling energy flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to the accompanying drawings and embodiments.

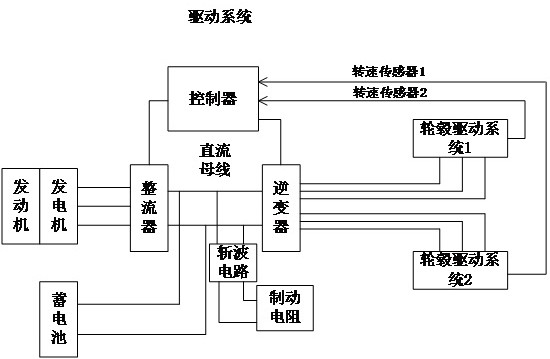

[0022] Such as figure 1 As shown, a driving system of a hybrid mining dump truck includes an engine, a generator, an electric drive system, a storage battery, a hub drive system 1 and a hub drive system 2;

[0023] The engine is connected to the generator, the generator and the battery are connected to the electric drive system, and the electric drive system is connected to the hub drive system 1 and the hub drive system 2 respectively;

[0024] The electric drive system includes a rectifier, a DC bus, a controller, an inverter and a braking resistor. One end of the rectifier is connected to the generator, and the other end of the rectifier is connected to the inverter through the DC bus. The inverters are respectively connected to the hub drive system. 1. The hub drive system 2 is connected, the battery and the braking resistor are connected to the DC bus, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com