Garbage disposal crusher

A technology of garbage disposal and pulverizer, applied in the field of machinery, can solve the problems of loud noise, easy blockage of sewers, low treatment efficiency, etc., to achieve the effect of fast and thorough discharge, preventing accumulation of sediment, and increasing kinetic energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

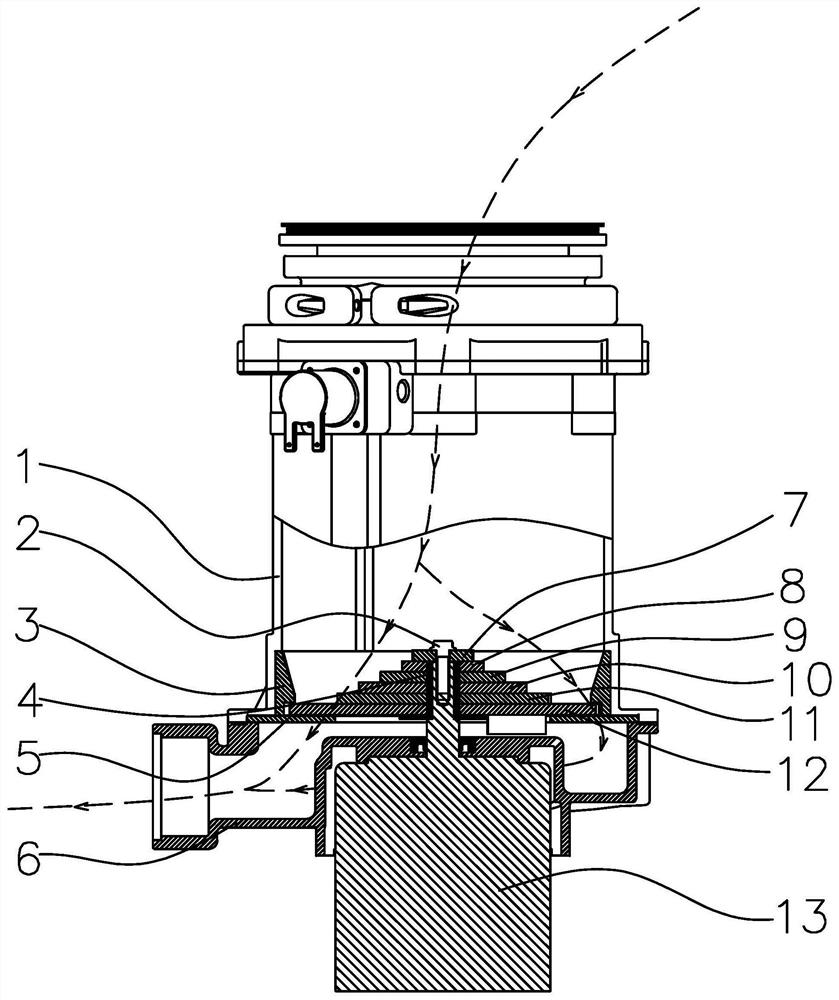

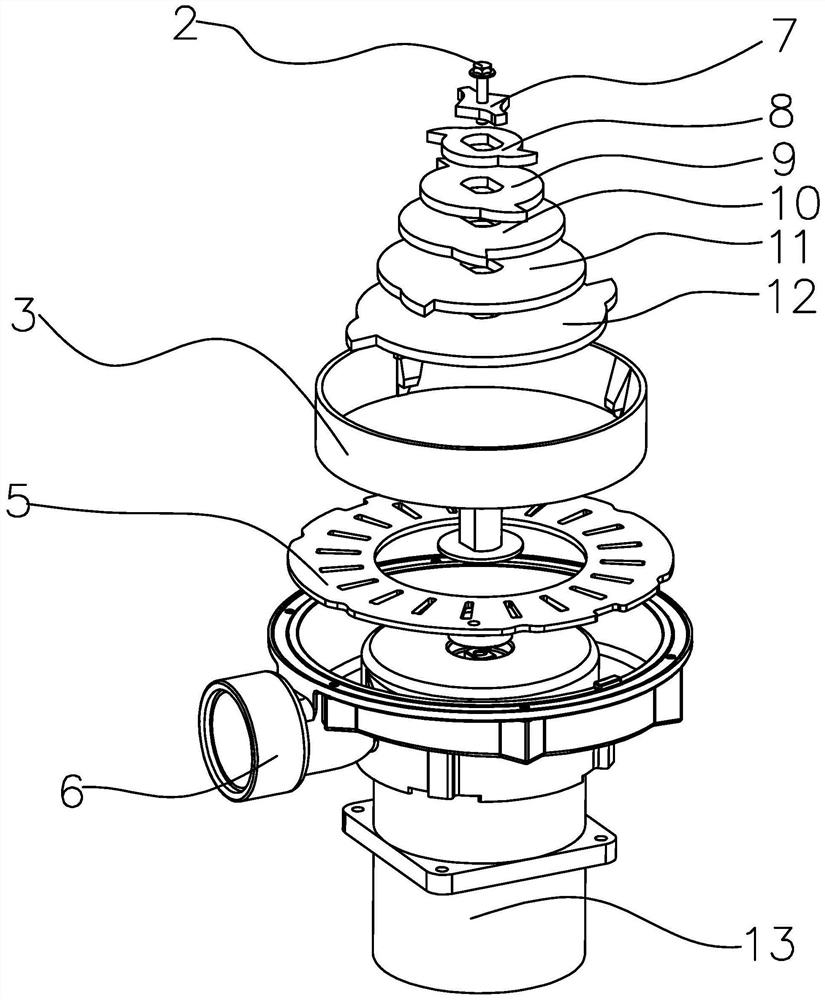

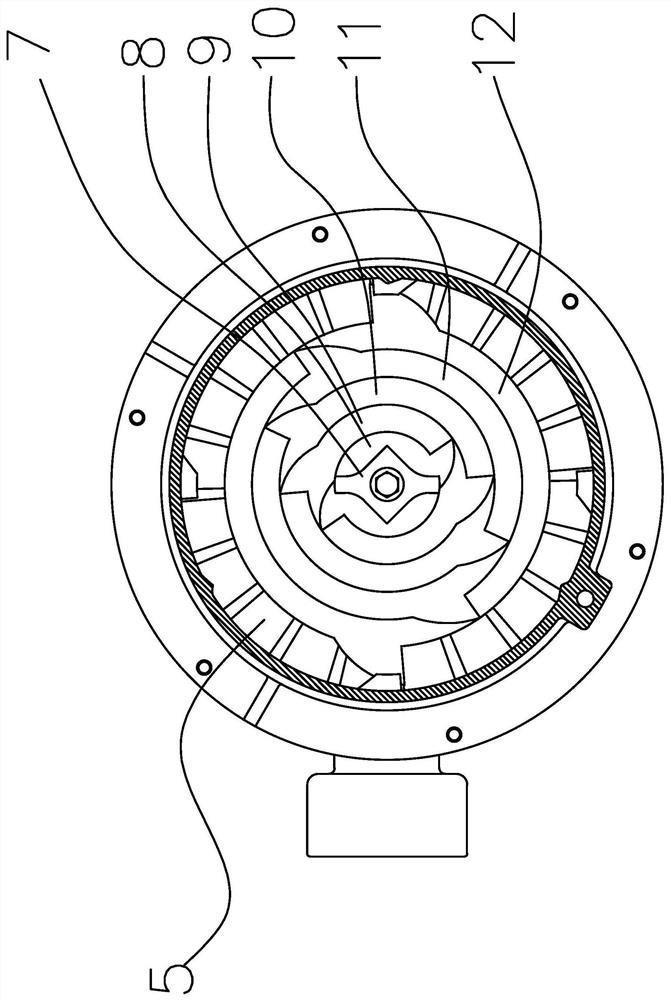

[0021] Such as Figures 1 to 3 As shown, the garbage disposal pulverizer includes a cylindrical shell 1, and the inside of the cylindrical shell 1 is a crushing chamber. The bottom of the crushing chamber is provided with a water outlet chamber 6. The top cover of 6 is provided with a cutting sieve plate 5, and several discharge holes are opened on the cutting sieve plate 5, and a motor 13 is arranged under the cylindrical shell 1, and the drive shaft of the motor 13 runs through the water outlet chamber 6 and the cutting sieve plate 5 upwards and enters the crushing chamber body, the driving shaft located in the crushing cavity is fixed with several stepped crushing teeth, and the stepped crushing teeth are set step by st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com