Degreasing hot air circulating furnace for zirconia ceramic materials

A technology of zirconia ceramics and hot air circulation, which is applied in the direction of furnaces, furnace components, furnace control devices, etc., can solve the problems of low heat exchange and degreasing efficiency, non-continuous adjustment, and non-adjustable air volume, so as to achieve degreasing discharge and practicality Strong, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

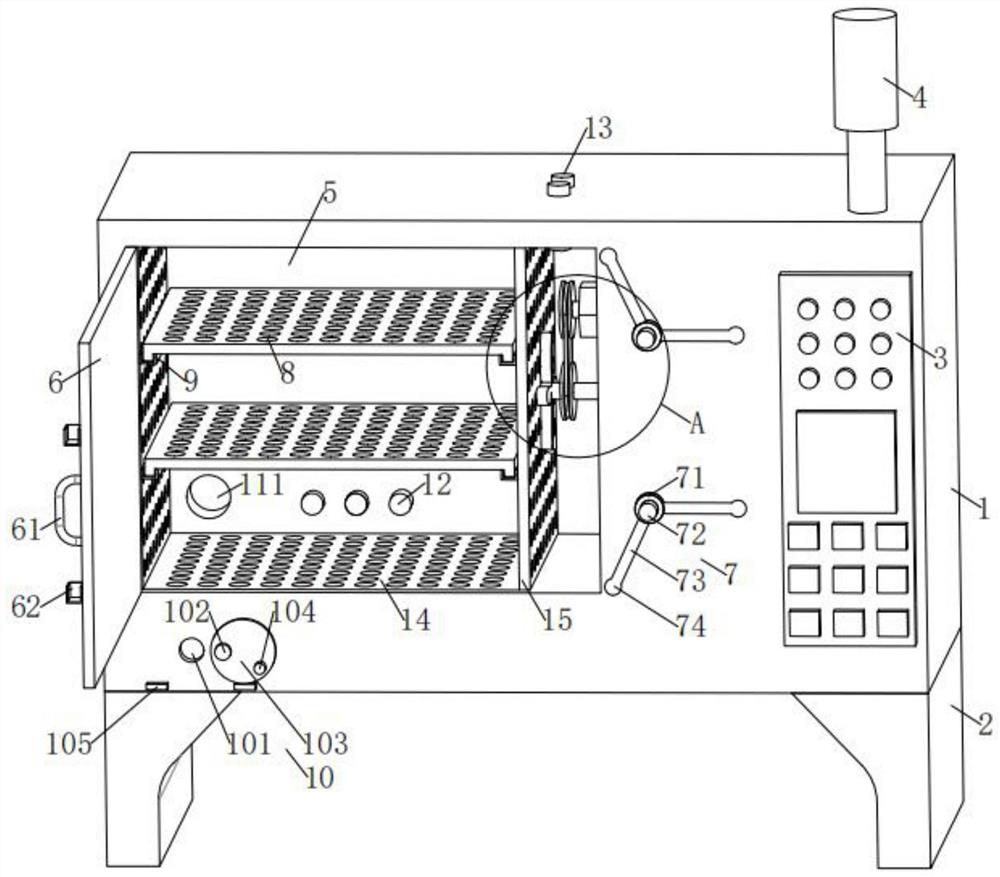

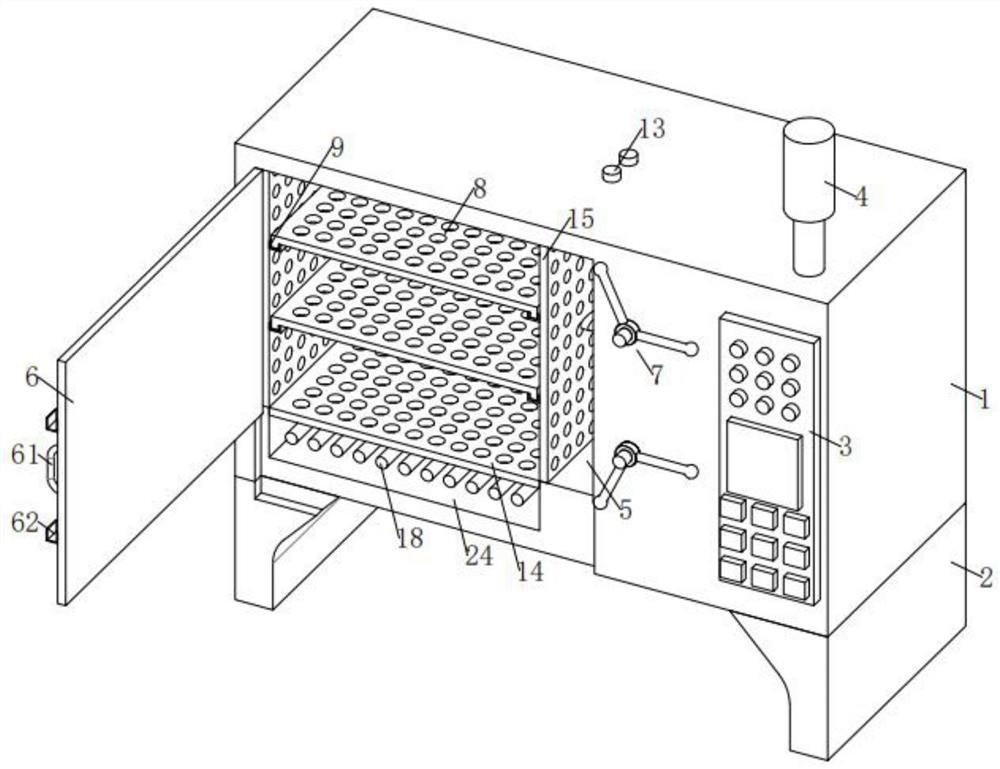

[0090] see Figure 1-7 , a degreasing hot air circulation furnace made of zirconia ceramic material, comprising:

[0091] The bottom of the furnace body 1 is fixed with two supporting feet 2, and the two supporting feet 2 are respectively arranged on the left and right sides of the bottom of the furnace body 1 to achieve good support for the furnace body 1;

[0092] The PLC control panel 3 fixedly installed on the right side of the front surface of the furnace body 1 is used for power control and intelligent temperature control of the entire circulation furnace. Program operation and other functions are the core control hub of this hot air circulation furnace;

[0093] A furnace cavity 5 is provided on the left side of the front surface of the furnace body 1, and the furnace cavity 5 is used to realize hot air circulation and heating;

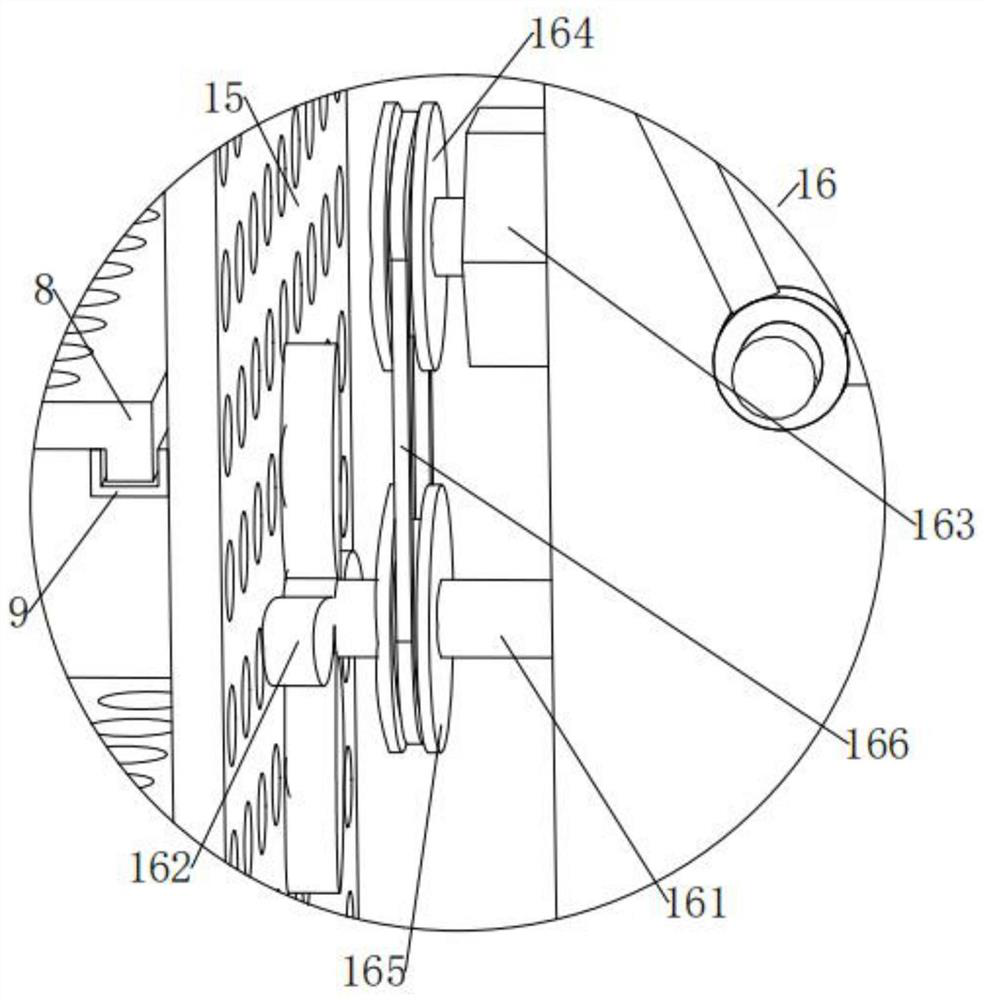

[0094] Two vertical mesh plates 15 are fixedly arranged between the upper and lower inner walls of the furnace cavity 5, the vertical mesh p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com