Method for detecting photoelectric property of laser Bar chip

A technology of optoelectronic performance and detection method, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of low efficiency of positioning mechanism, difficult operation, incontinence, etc., to achieve convenient and accurate power supply, simple fine-tuning positioning, and high detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in further detail below through specific examples.

[0065] A method for detecting photoelectric properties of a laser bar chip, comprising the following steps:

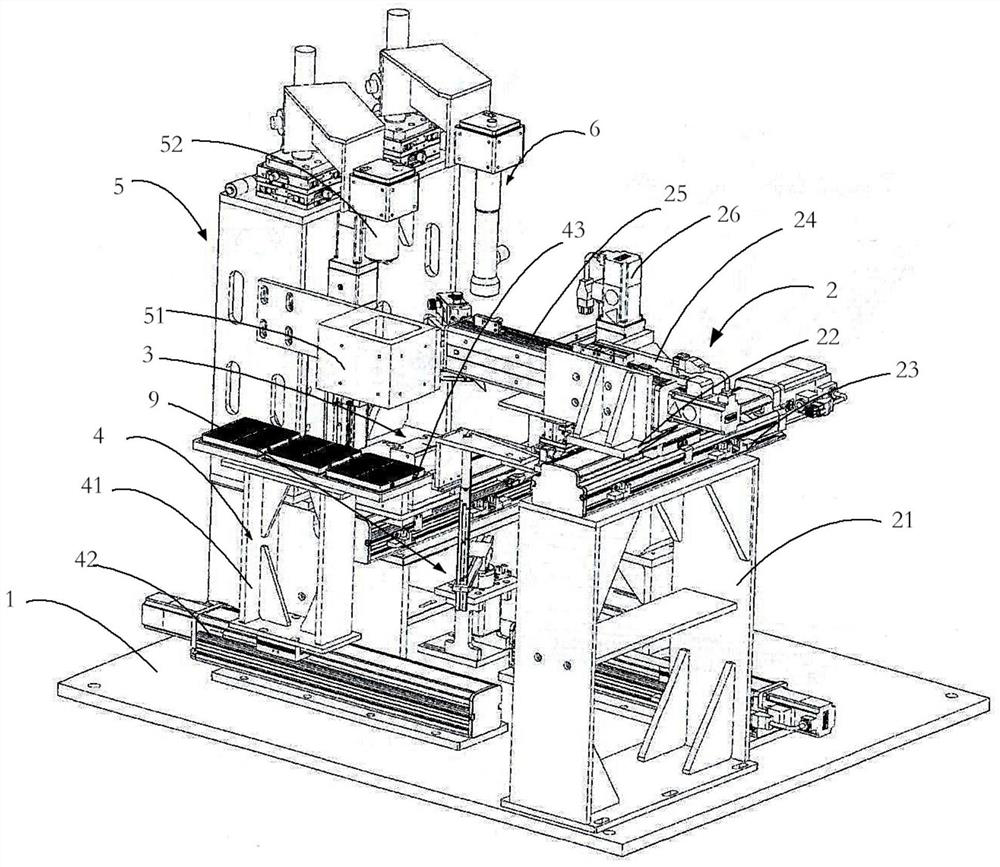

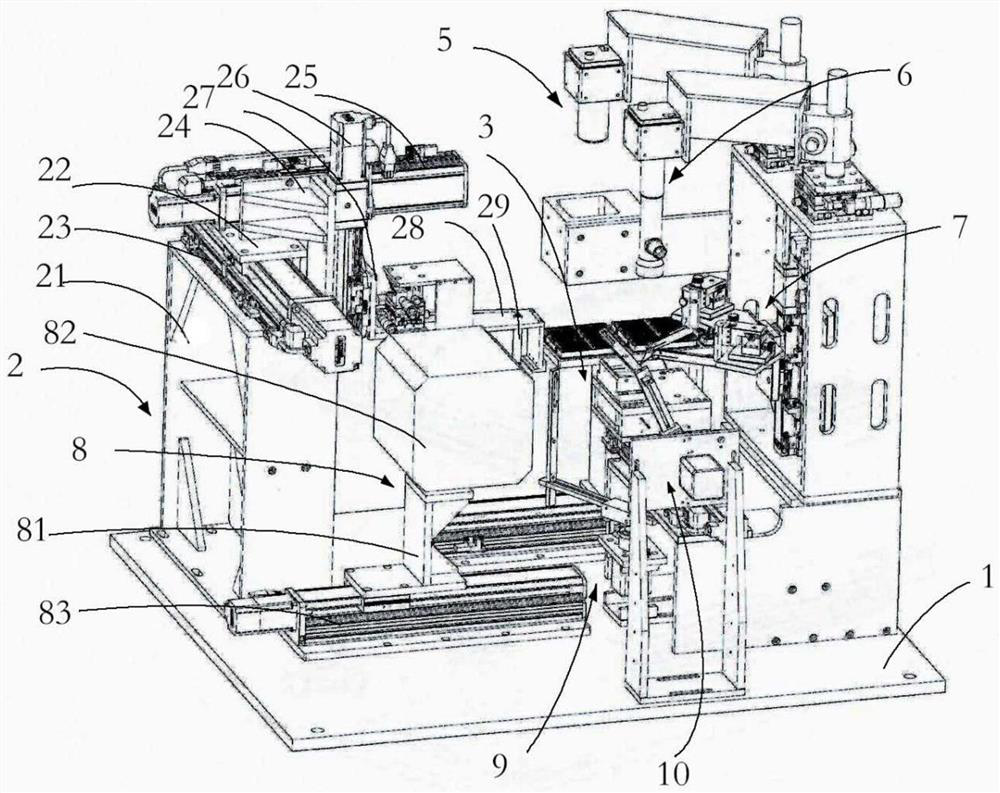

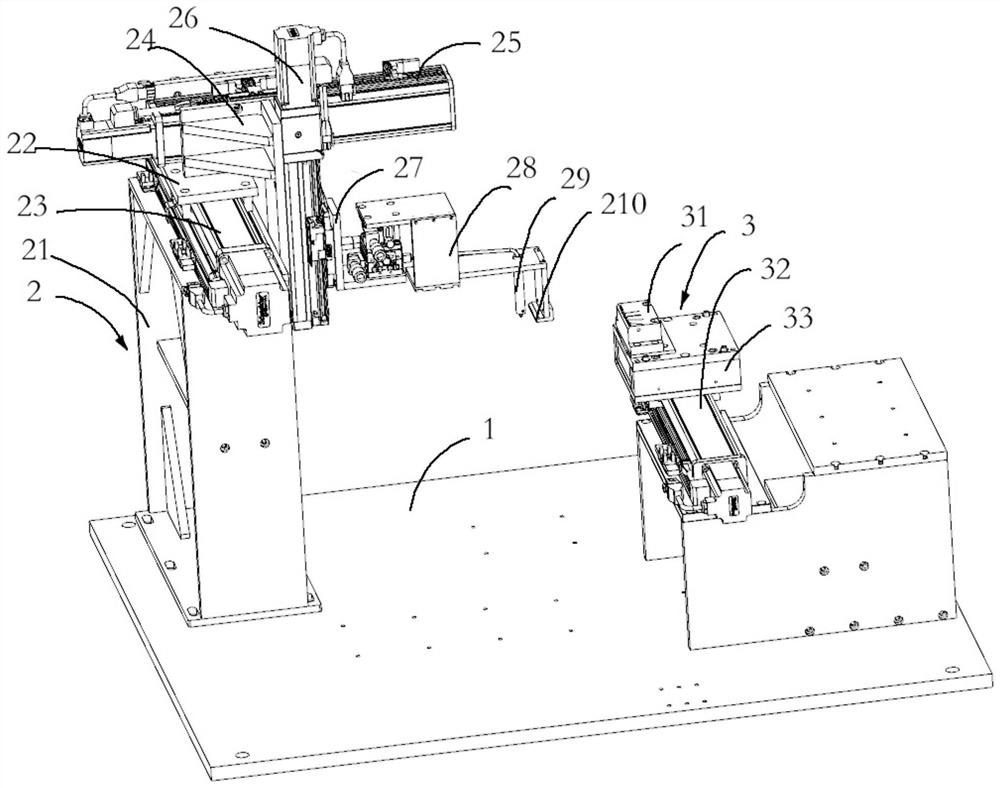

[0066] S1, place the Bar box 43 with many Bar bars on the Bar bar detection station of the placement seat 41; wherein, the Bar box 43 is provided with several Bar bar placement grooves 432, each Bar bar All are placed in the corresponding Bar bar placement groove 432; Place at least two Bar barrel boxes 43 on the placement seat 41, after the Bar bars in one of the Bar box boxes 43 have all been detected, the placement seat 41 moves a station to make The next Bar box 43 moves to the Bar bar detection station for the next round of detection.

[0067] S2. Use the Bar detection camera 52 to take photos of the Bar box 43 on the Bar detection station to confirm the placement position of the Bar in the Bar box 43; wherein, the parallel ring light can be used to supplement ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com