Cloth bag lower pattern plate fixing device for circular cloth bag dust remover and using method thereof

A technology of bag dust collector and fixing device, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of filter bag damage, loss, boiler shutdown, etc., to prevent filter bag damage, design Reasonable, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

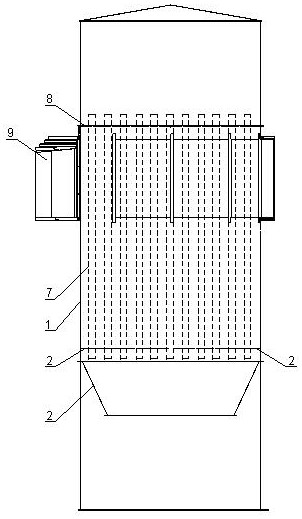

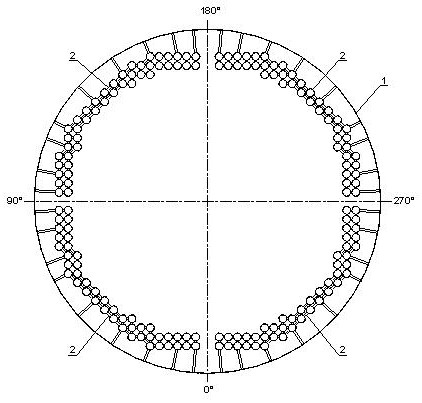

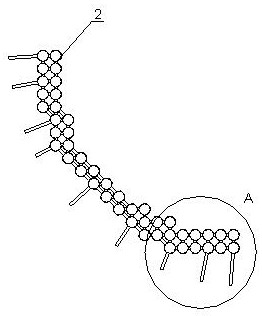

[0030] Such as Figure 1 to Figure 9 As shown, a bag lower flower plate fixing device for a round bag filter is composed of a fixed lower flower plate 2 and a bag installation buckle 5, and the fixed lower flower plate 2 is used as the outermost two inside the fixed round bag filter. The overall frame of the ring filter bag 7, the cloth bag installation buckle 5 fixes the filter bag 7 on the fixed flower plate 2;

[0031] The fixed lower flower plate 2 is composed of a cloth bag installation ring 3, an installation ring connector 4 and a tower wall connection plate 6. The width of a single cloth bag installation ring is 6mm, the width L1 of the installation ring connector is 40mm, and the width L2 of the tower wall connection plate is 40mm; The cloth bag installation ring 3 is a fixed ring of the filter bag 7, and the installation ring connector 4 connects the adjacent cloth bag installation rings 3 into a whole.

[0032] Wherein, the tower wall connecting plate 6 fixes the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com