Profile steel cold roll forming feeding device

A technology of cold-formed forming and feeding device, applied in feeding device, positioning device, storage device, etc., can solve the problems of dimensional deformation, overload damage of forming equipment, increase production cost, etc., to improve quality, improve production efficiency, The effect of reducing usage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

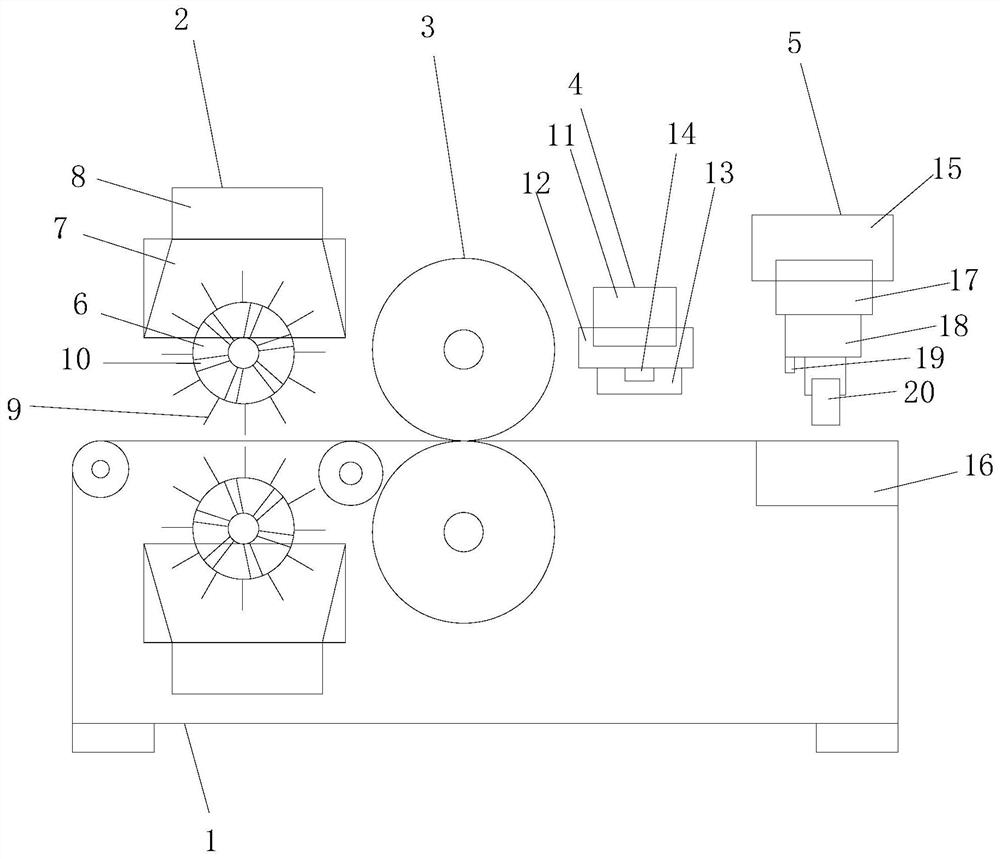

[0015] refer to figure 1 , a profile steel cold-formed feeding device of the present invention, comprising a frame 1, a dust removal mechanism 2, a pre-flattening mechanism 3, a surface detection mechanism 4 and a positioning correction mechanism 5, the top of the frame 1 is provided with a dust removal mechanism 2, The dust removal mechanism 2 includes a dust removal brush roller 6, a dust suction cover 7 and a vacuum cleaner 8. The dust removal brush roller 6 is symmetrically arranged on the top of the frame 1, and the dust suction cover 7 is arranged on the outside of the dust removal brush roller 6. A vacuum cleaner 8 is installed on the dust collection cover 7, and a pre-flattening mechanism 3 is arranged on the right side of the dust removal mechanism 2, and the pre-flattening mechanism 3 is composed of two groups of vertically symmetrical flattening rollers. The right side of the flat mechanism 3 is provided with a surface detection mechanism 4, the right side of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com