Adjustable ceramic tile cutter for architectural decoration

A cutter and ceramic tile technology, which is applied in construction, building construction, work accessories, etc., can solve the problems of low cutting accuracy and safety, and achieve the effect of saving materials, avoiding waste, and avoiding tile cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

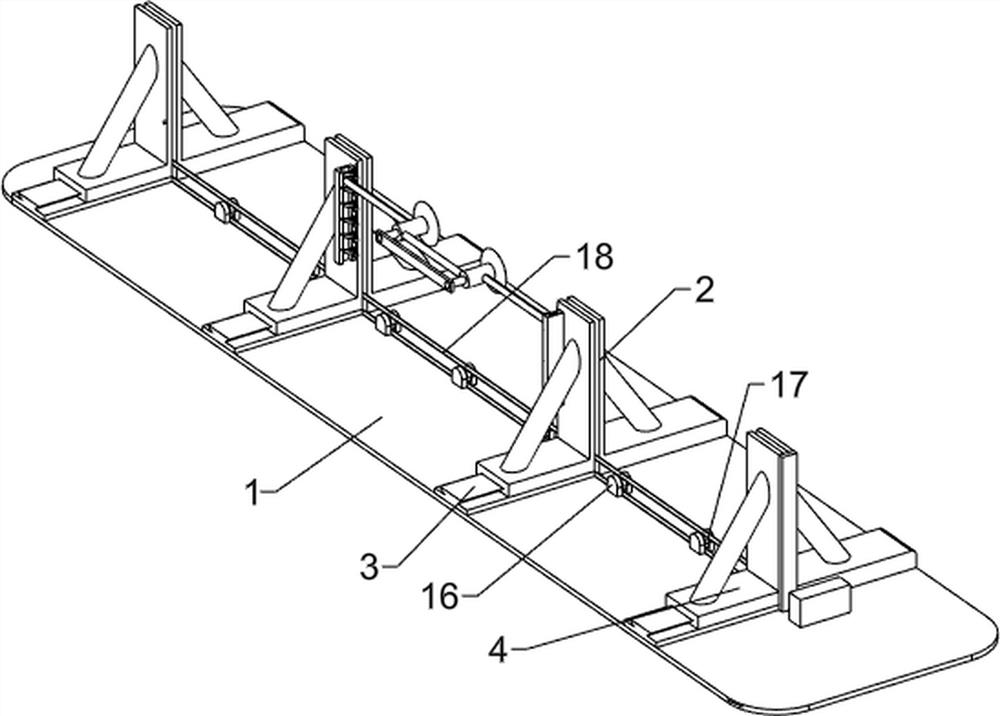

[0024] A tile adjustable cutter for building decoration, such as Figure 1-4 As shown, it includes a bottom plate 1, a fixed L-shaped top plate 2, a straight slide rail 3, a movable L-shaped top plate 4, a mobile cutting device 5 and an adjustment mechanism 6, and four fixed L-shaped top plates 2 are evenly spaced on the rear side of the top of the bottom plate 1. Four straight slide rails 3 are evenly spaced on the front side of the top of the base plate 1, and a movable L-shaped top plate 4 is slidably arranged on the straight slide rails 3. The fixed L-shaped top plate 2 cooperates with the movable L-shaped top plate 4, and the bottom plate 1 is provided with The mobile cutting device 5 is located above the fixed L-shaped top board 2 and the movable L-shaped top board 4 , and an adjustment mechanism 6 is arranged between the bottom board 1 and the mobile cutting device 5 .

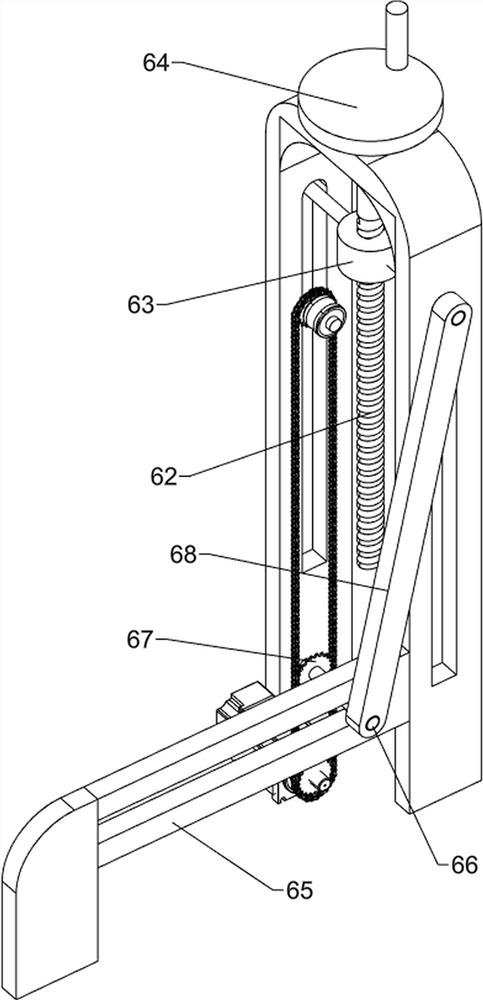

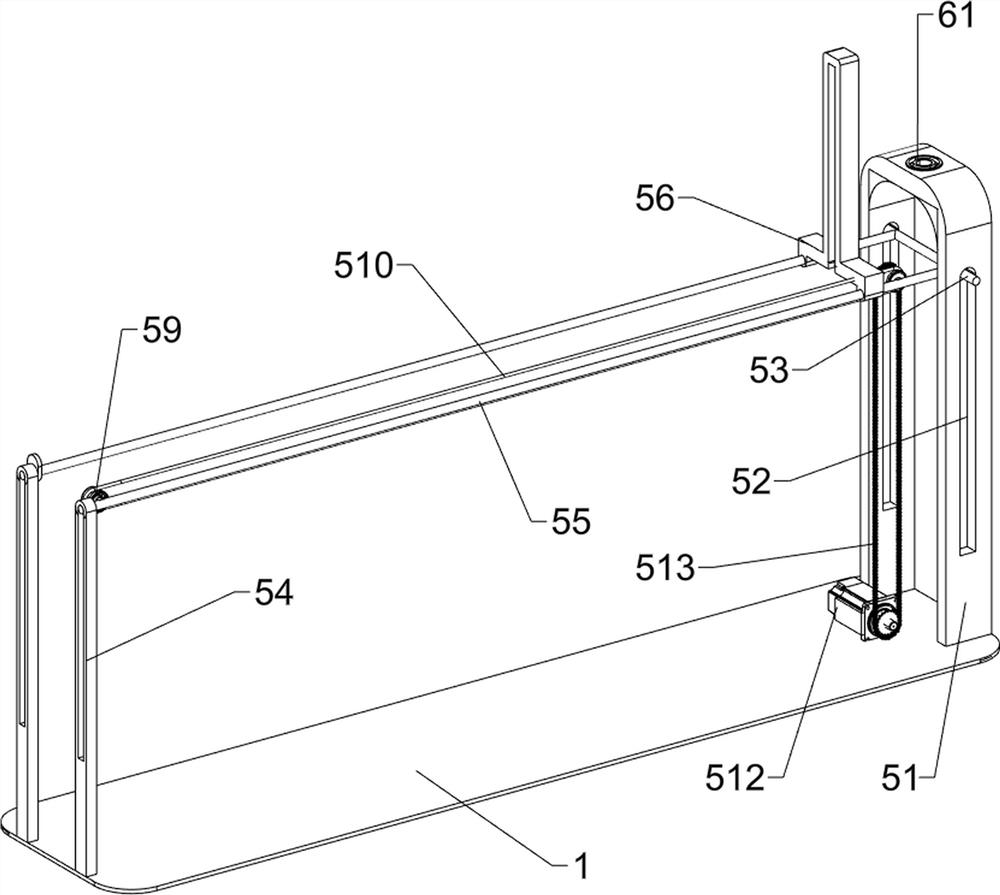

[0025] Mobile cutting device 5 includes N-shaped plate 51, slide bar 53, guide plate 54, guide rod 5...

Embodiment 2

[0029] On the basis of Example 1, such as Figure 5-7 As shown, it also includes a straight guide plate 7, a sliding rod 8, a suction cup cylinder 9, a connecting rod 10, a piston 11, a pull rod 12, a pawl 13, an elastic member 14 and a stopper 15, and the two movable L-shaped The top plate 4 is symmetrically arranged with straight guide plates 7, the two straight guide plates 7 are slidingly equipped with slide rods 8, the inner ends of the two slide rods 8 are provided with suction cup cylinders 9, and a connecting rod is provided between the two suction cup cylinders 9. Rod 10, piston 11 is arranged slidingly in two sucker cylinders 9, piston 11 cooperates with sucker cylinder 9, a pull rod 12 is arranged between two pistons 11, and two straight guide plates 7 are provided with spines evenly spaced on the opposite sides and rear sides. An elastic member 14 is arranged between the pawl 13 and the ratchet 13 and the straight guide plate 7 , and stoppers 15 are arranged on the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap