Guide steel wire assembly injection molding system

A technology of injection molding and steel wire, applied in the direction of wire processing, other household appliances, household appliances, etc., can solve the problems of low product qualification rate and low work efficiency, so as to improve product quality, reduce scrap rate, and increase bending processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing provides the preferred embodiment of the present invention, what is disclosed is only the preferred embodiment of the present invention, certainly can not limit the scope of rights of the present invention with this, therefore the equivalent change made according to the claims of the present invention , still belong to the scope covered by the present invention.

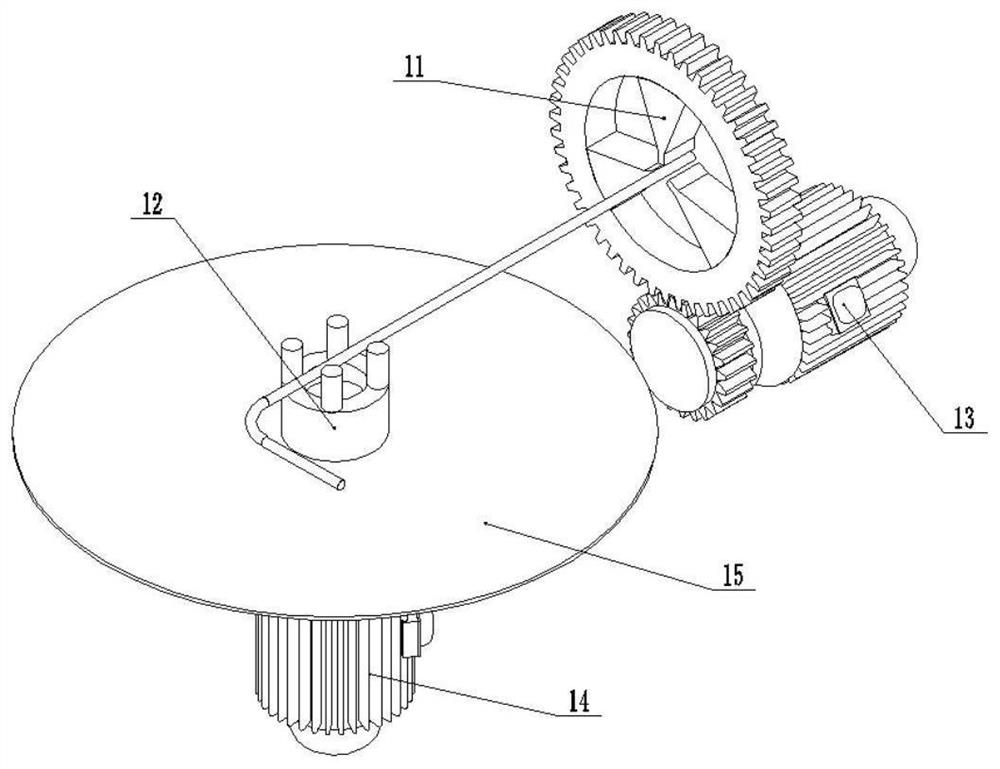

[0023] A processing and positioning fixture for a transmission side cover disclosed by the present invention is characterized in that it includes a forming device, a stamping device, an injection molding device, and a collecting device connected between the forming device and the stamping device; see figure 1 , the forming device includes a motor, a through-hole chuck 11, a bending head 12 and a baffle 15; the motor includes a first motor 13 and a second motor 14; the through-hole chuck 11 is provided with an outer ring Gear, the gear meshes with the output gear s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap