Radial tire

A radial tire and tire technology, applied in tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve the problems of reducing tire rolling resistance, affecting tire production efficiency, and component adhesion, reducing rolling resistance. , to achieve the effect of convenience and great binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical scheme of the present invention, the present invention will be described in detail below through specific examples.

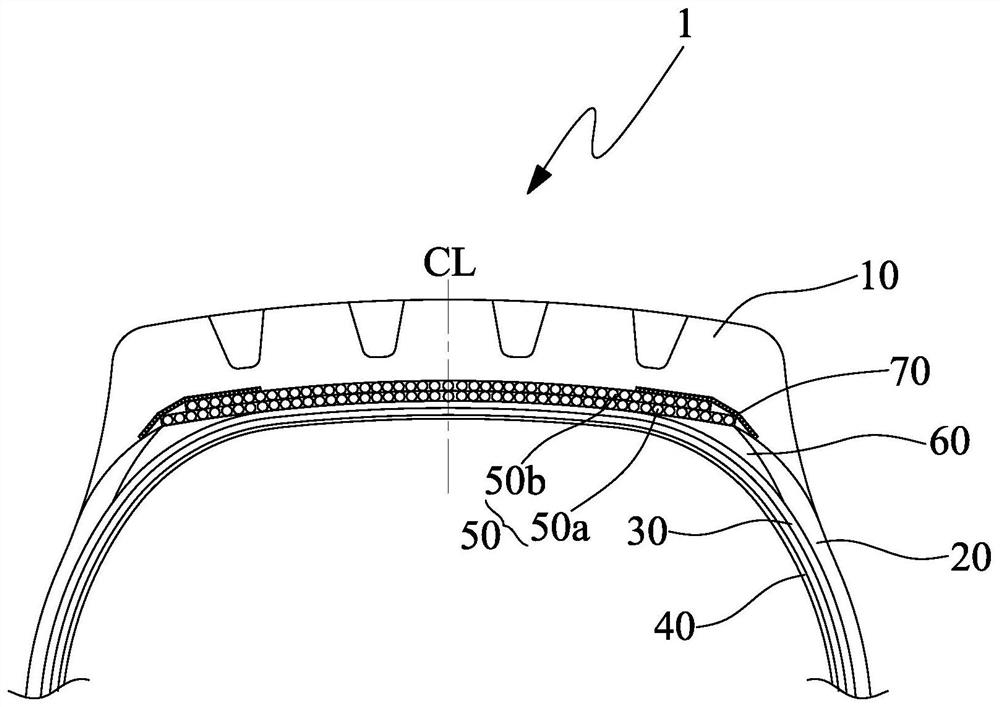

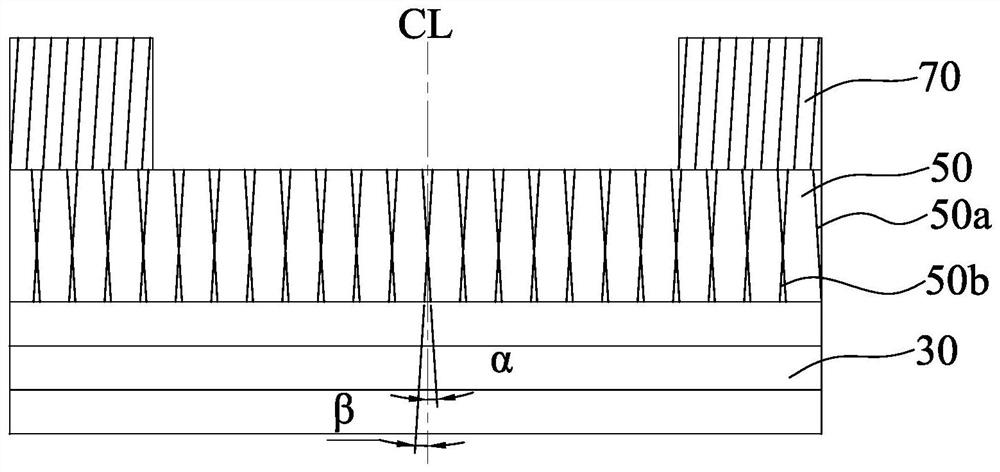

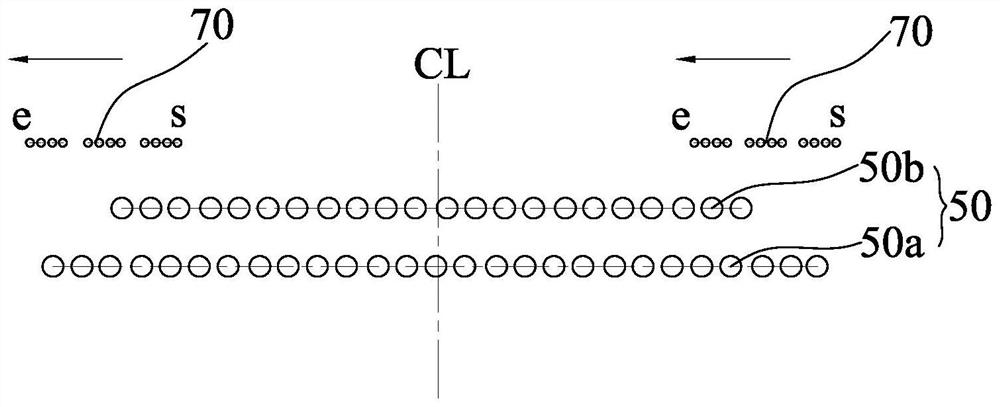

[0026] First define the orientation of the tire: CL represents the center plane of the tire; the horizontal direction in the figure represents the axial direction of the tire, the vertical direction represents the radial direction of the tire, and the direction perpendicular to the paper surface represents the circumferential direction of the tire; the plane CL close to the tire center represents Inside, away from the tire center plane CL denotes the outside.

[0027] Such as figure 1 As shown, it is a partial cross-sectional schematic diagram of the first embodiment of the radial tire of the present invention. The tire 1 includes a tread portion 10, a carcass 30 and a belt layer located between the radially below the tread portion 10 and the radially above the carcass 30. 50. The bead portion 20, the inner surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com