Odorless transportation device for garbage treatment system

A technology for a garbage disposal system and a transportation device is applied in the field of odorless transportation devices for garbage disposal systems, which can solve the problems of reduced work efficiency of workers, polluted working environment, and odor diffusion, etc. The effect of odor diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

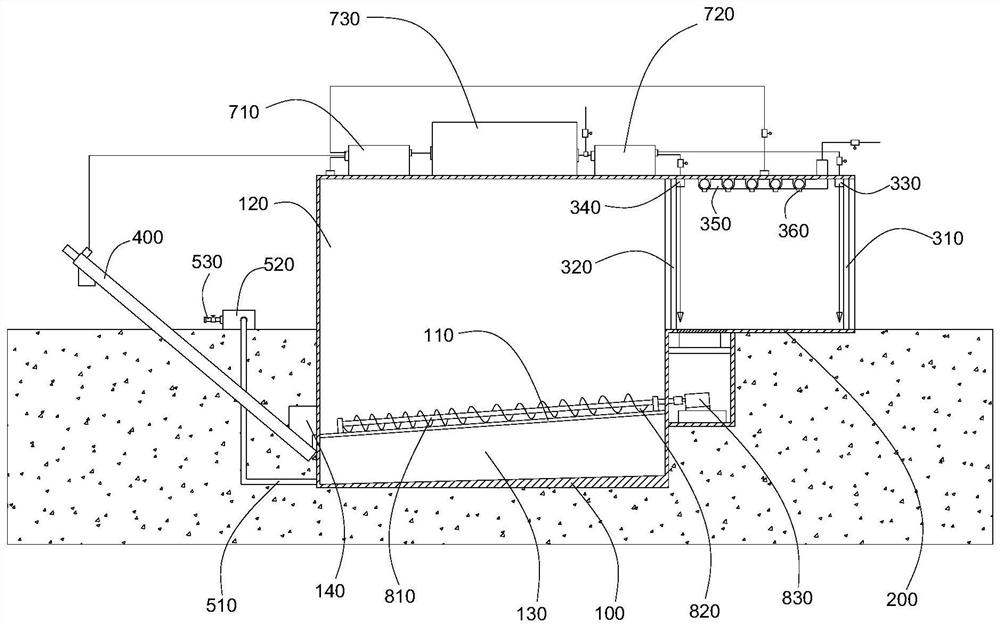

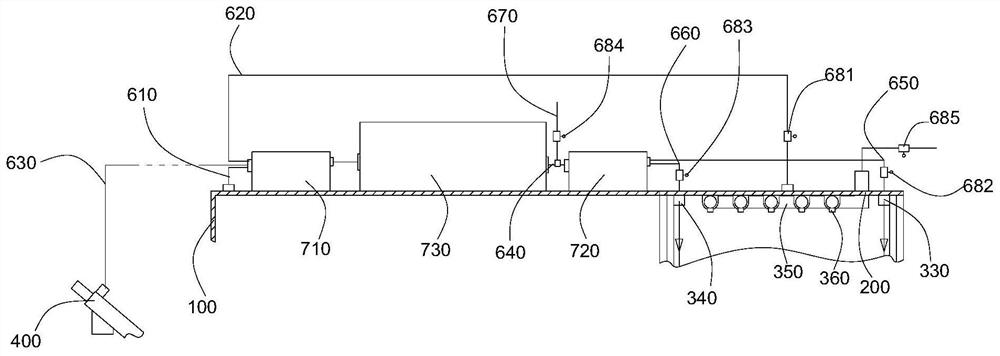

[0020] Such as figure 1 , figure 2 As shown, a specific embodiment of the present invention discloses an odorless transportation device for a garbage treatment system, including a transfer bin 100, a delivery bin 200 located on the top of one side of the transfer bin 100, and the delivery bin 200 is connected to the transfer bin 100. The transfer bin 100 is connected, the opening of the delivery bin 200 away from the transfer bin 100 is provided with a first electric door 310, and the connection between the delivery bin 200 and the transfer bin 100 is provided with a second electric door 320; The inside of the transfer bin 100 is fixed with a filter plate 110, the filter plate 110 is arranged obliquely, and divides the transfer bin 100 into a first chamber 120 and a second chamber 130, and the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com