Raw materials for preparing matchstick friction layer and method and device for coating surface of ceramic with matchstick friction layer

A ceramic surface and friction layer technology, which is applied in the field of ceramic product processing, can solve the problems of friction layer deformation, non-existence, and uneven thickness of matches, and achieve the effects of avoiding ceramic damage, preventing ceramic movement, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

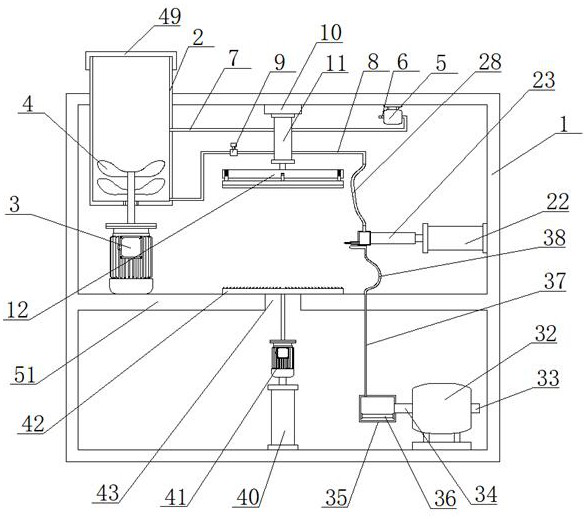

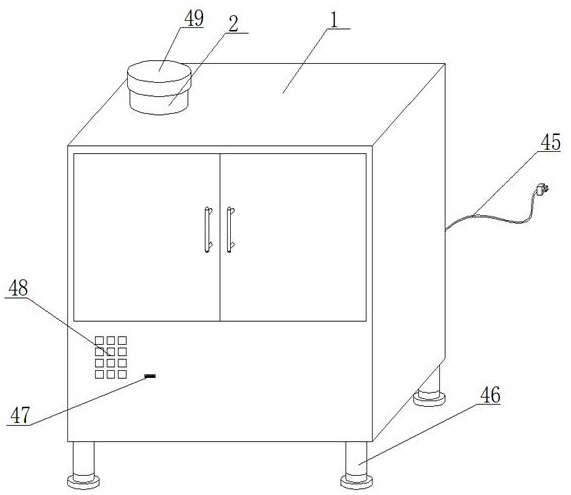

[0034] As a preferred embodiment of the present invention, the top of the mixing tank 2 is fitted with a top cover 49 through external threads and internal threads.

[0035] As a preferred embodiment of the present invention, support legs 46 are fixedly installed at corners of the bottom of the housing 1 .

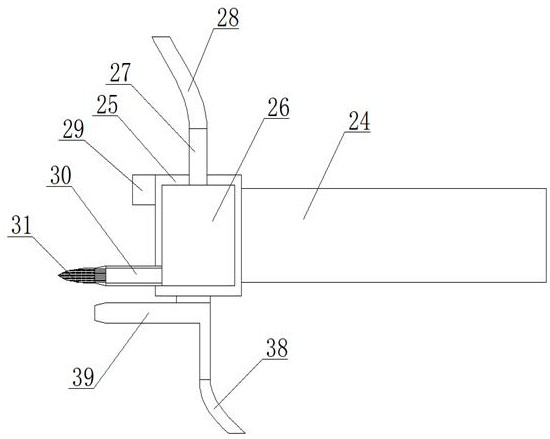

[0036] As a preferred embodiment of the present invention, one side of the housing 1 is fixedly connected with a power cord 45, and one end of the power cord 45 is connected with a plug, and the power cord 45 is respectively connected to the processor 50 and the motor through a power supply circuit. 1 3. Air pump 1 5. Electric valve 9. Electric push rod 1 11. Pressure sensor 19. Electric push rod 2 22. Infrared sensor 29. Air pump 2 32. Electric heating rod 36. Electric push rod 3 40. Motor 2 41. USB The interface 47 is electrically connected to the operation button 48 .

[0037] As a preferred embodiment of the present invention, the processor 50 is connected with the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com