Washing-free vitrification agent and use method thereof

A pottery, water-free technology, applied in the direction of metal material coating process, can solve the problems of cumbersome operation, rusted and scrapped workpiece, reduced coating efficiency, etc. The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

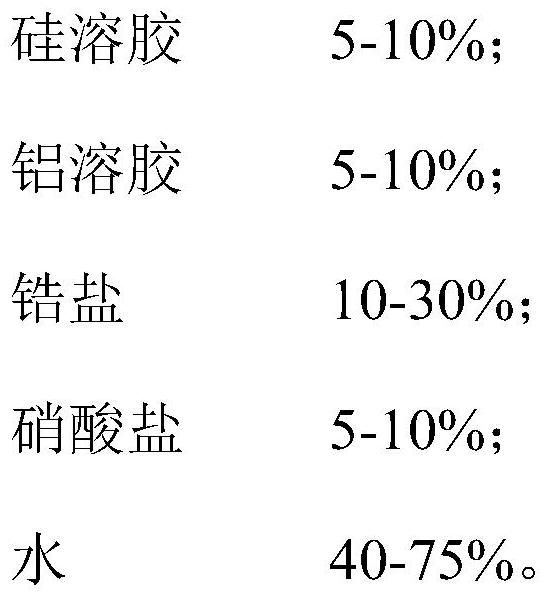

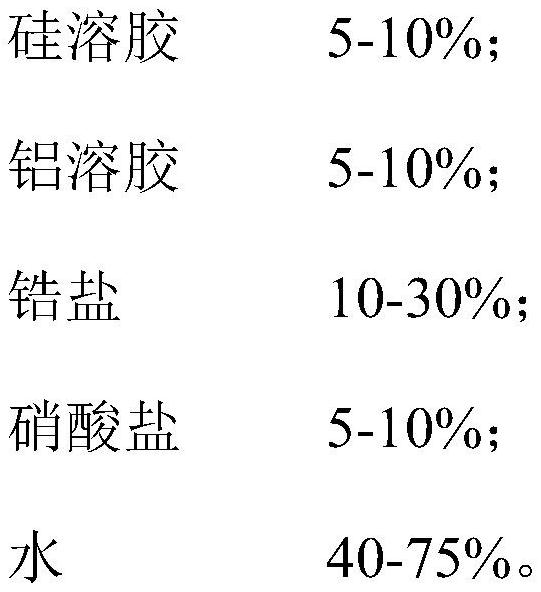

[0021] A non-washing pottery agent, by mass percentage, consists of the following components:

[0022] Aluminum sol 5%, silica sol 5%, fluozirconic acid 6%, ammonium fluozirconate 7%, manganese nitrate 5%, water balance.

[0023] The above-mentioned components are mixed according to the existing technology to prepare the corresponding no-wash vitrifier.

[0024] A kind of using method of described no-wash pottery agent, comprises the following steps:

[0025] S1. Dilute the non-washing vitrifying agent with water to a diluent with a mass percentage of the vitrifying agent of 2%;

[0026] S2. Adjust the pH of the diluent to 4.5 with ammonium bicarbonate;

[0027] S3. Put the workpiece with a clean surface into the diluent and soak for 5 minutes, then take it out and dry it.

[0028] The water for dilution can be tap water, which has a wide range of sources and low cost.

[0029] The effect test is carried out on the workpiece made of carbon steel:

[0030] 1. Treat the wor...

Embodiment 2

[0033] A non-washing pottery agent, by mass percentage, consists of the following components:

[0034] Aluminum sol 5%, silica sol 5%, fluozirconic acid 6%, ammonium fluozirconate 7%, manganese nitrate 5%, water balance.

[0035] The above-mentioned components are mixed according to the existing technology to prepare the corresponding no-wash vitrifier.

[0036] A kind of using method of described no-wash pottery agent, comprises the following steps:

[0037] S1. Dilute the non-washing vitrifying agent with water to a diluent with a mass percentage of vitrifying agent of 4%;

[0038] S2. Adjust the pH of the diluent to 4.5 with ammonium bicarbonate;

[0039] S3. Put the workpiece with a clean surface into the diluent and soak for 10 minutes, then take it out and dry it.

[0040] The water for dilution can be tap water, which has a wide range of sources and low cost.

[0041] The effect test is carried out on the workpiece made of carbon steel:

[0042] 1. Treat the workpi...

Embodiment 3

[0045] A non-washing pottery agent, by mass percentage, consists of the following components:

[0046] 10% of aluminum sol, 5% of silica sol, 10% of fluozirconic acid, 8% of ammonium fluozirconate, 5% of aluminum nitrate, and the balance of water.

[0047] The above-mentioned components are mixed according to the existing technology to prepare the corresponding no-wash vitrifier.

[0048] A kind of using method of described no-wash pottery agent, comprises the following steps:

[0049] S1. Dilute the non-washing vitrifying agent with water to a diluent with a mass percentage of the vitrifying agent of 5%;

[0050] S2. Adjust the pH of the diluent to 5.0 with ammonium bicarbonate;

[0051] S3. Put the workpiece with a clean surface into the diluent and soak for 10 minutes, then take it out and dry it.

[0052] The water for dilution can be tap water, which has a wide range of sources and low cost.

[0053] The effect test is carried out on the workpiece made of carbon steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com