Cooling wall with pre-coated slag crust

A cooling wall and slag skin technology, which is applied in the direction of cooling devices, etc., to achieve the effects of improving thermal conductivity, improving fire resistance, and reducing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

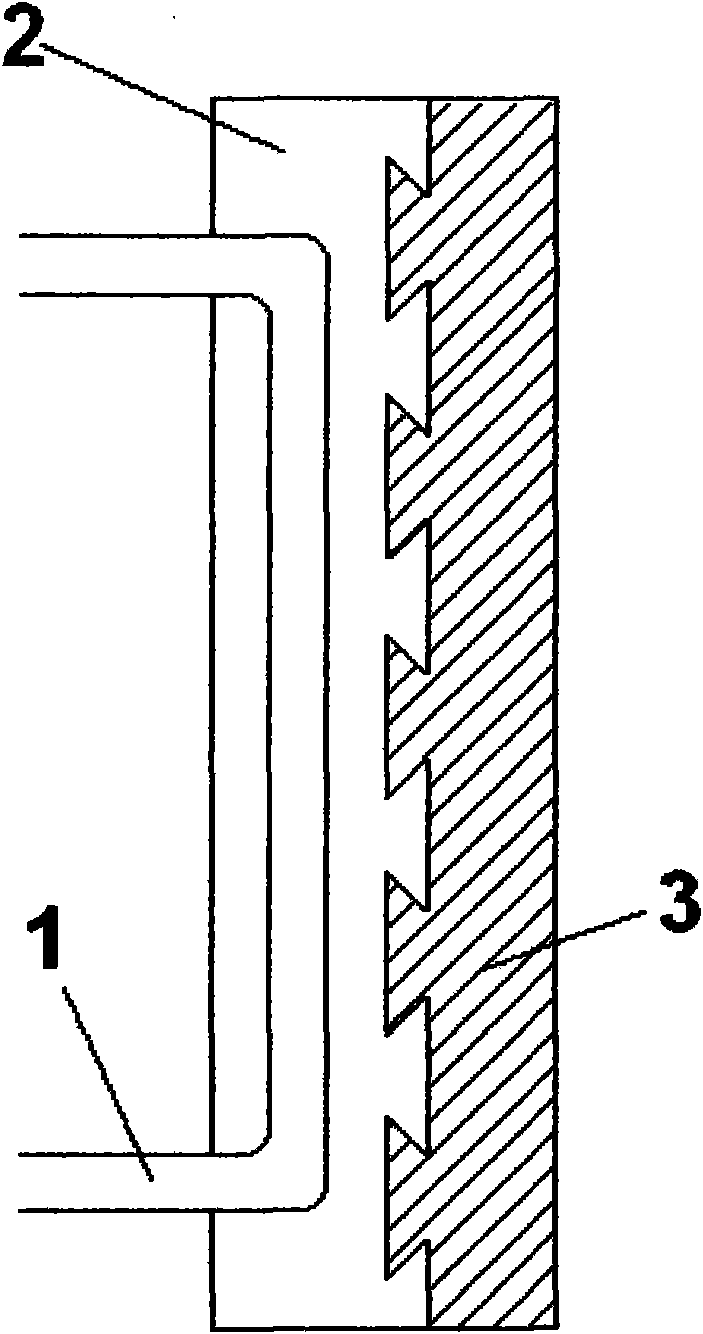

Image

Examples

Embodiment Construction

[0025] Refractory material ingredients: by weight, 30 parts of bauxite powder, 50 parts of corundum powder, 50 parts of silicon carbide powder, 10 parts of silicon micropowder, 15 parts of alumina micropowder, 15 parts of calcium aluminate cement, and 2 parts of water reducing agent.

[0026] The calcium silicate powder has 15 parts by weight.

[0027] Add the above powder into tap water and stir evenly to form a slurry with good fluidity.

[0028] Prepare a copper wall with a dovetail groove, according to the designed slag thickness of 150mm (not including the depth of the dovetail groove), use the copper stave as a side formwork, and support the mold. Spread steel fibers in the mold, carefully spread to ensure that the volume of steel fibers accounts for 15% of the total space volume in the mold.

[0029] Inject the above-mentioned stirred mud into the mold filled with steel fibers.

[0030] Cooperate with the vibration of the mold to ensure that the entire steel fiber gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com