Immunoglobulin binding protein and its application

An immunoglobulin and binding protein technology, applied in the direction of immunoglobulin, application, separation method, etc., can solve the problems of high requirements on physical and chemical properties, unsatisfactory binding antibody loading, poor resistance to alkaline reagents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1 Preparation of protein multimers

[0060] Engineering bacteria expression:

[0061] All the gene synthesis work in this experiment was entrusted to Nanjing GenScript to express the strain E.coli BL (DE3).

[0062] The protein multimer prepared in this example is a six-segment repeat, and its monomer is obtained by splicing partial fragments of E-domain, C-domain and Z-domain:

[0063] E-domain

[0064] AQHDEAQQNA FYQVLNMPNL NADQRNGFIQ SLKDDP SQSA NVLGEAQKLN DSQAPK

[0065] D-domain

[0066] ADAQQNNFNKDQQSAFYEILNMPNLNEAQRNGFIQSLKDDPSQSTNVLGEAKKLNESQAPK

[0067] A-domain

[0068] ADNNFNKEQQNAFYEILNMPNLNEEQRNGFIQSLKDDPSQSANLLSEAKKLNESQAPK

[0069] B-domain

[0070] ADNKFNKEQQ NAFYEILHLP NLNEEQRNGF IQSLKDDPSQ SANLLAEAKK LNDAQAPK

[0071] C-domain

[0072] ADNKFNKEQQ NAFYEILHLP NLT EEQRNGF IQSLKDDPSV SKEILAEAKK LNDAQAPK

[0073] Z-domain

[0074] VDNKFNKEQQ NAFYEILHLP NLN EEQRNAF IQSLKDDP SQ SANLLAEAKK LNDAQAPK

[0075] The sequence of the resulti...

Embodiment 2

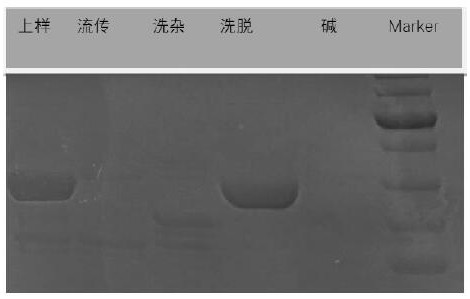

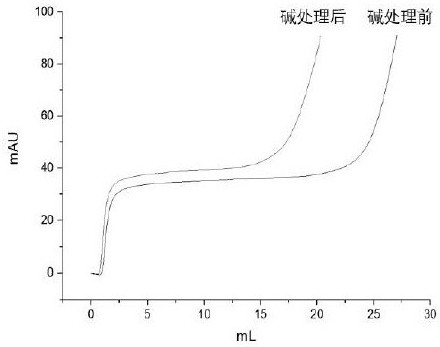

[0140] Example 2 Preparation of Protein A Affinity Filler

[0141] activation

[0142] 1. Accurately measure 300ml of 2mol / L NaOH solution, fully mix the solution with 200g of dried PMMA microspheres and pour it into the reaction kettle, turn on the stirring motor, set the rotation speed to 200rpm, set the temperature of the water bath to 40°C, and seal the reaction. 30min.

[0143] 2. Accurately measure 125ml of dimethylformamide and 75ml of 1,4-butanediol glycidyl ether into the reaction kettle, and seal the reaction for 2.5h.

[0144] 3. Remove the reactor, pour the microsphere mixture into a suction filter funnel, drain and rinse with 2 CV of deionized water. Then wash with 2CV of alcohol and deionized water respectively, and drain until no water drips.

[0145] coupling

[0146] 1. Accurately weigh 10 g of the activated microspheres and place them in a washed and dried conical flask.

[0147]2. Weigh 0.3g of the ligand and fully dissolve it with 12.8ml of buffer. Ad...

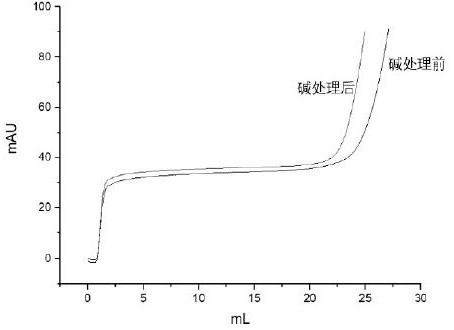

Embodiment 3

[0152] Example 3 Preparation of Protein A affinity filler

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com