Concrete transporting method used for small-diameter tunnel of narrow working well

A transportation method and concrete technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as low efficiency, achieve efficient transportation, improve construction efficiency, and ensure construction continuity and construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

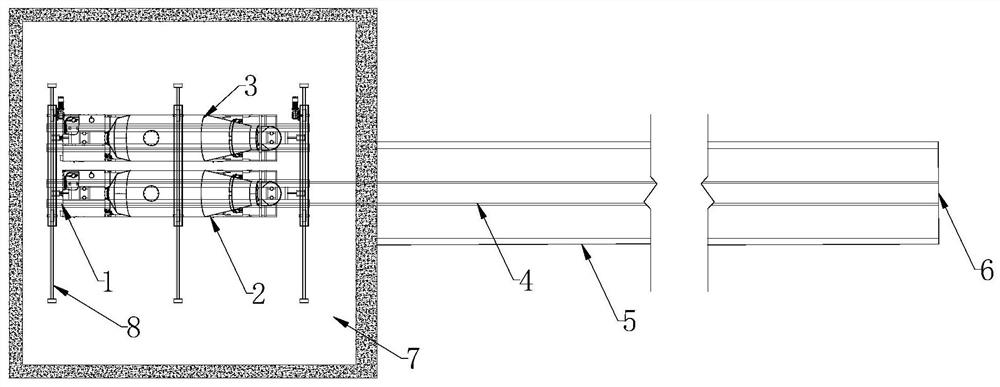

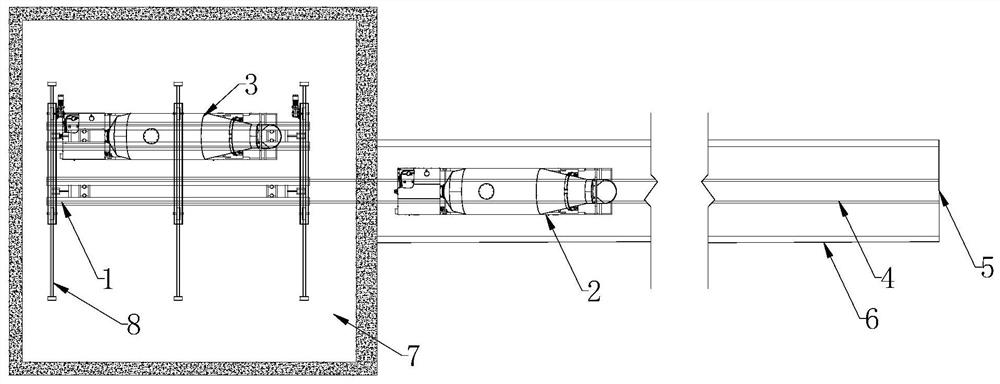

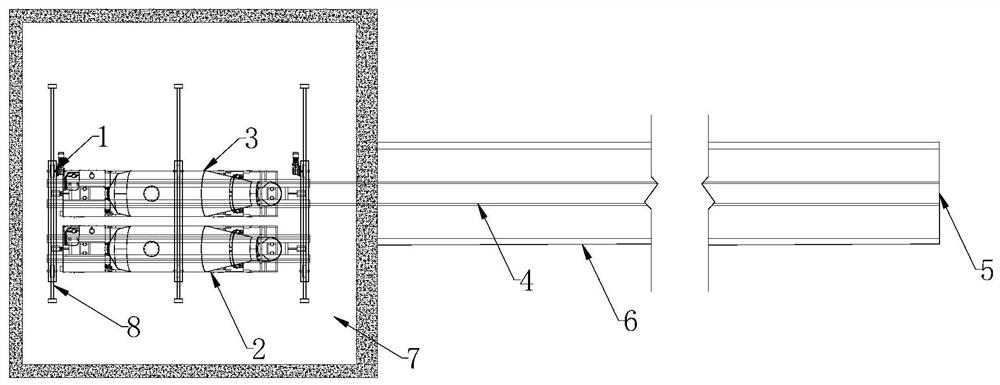

[0025] In this embodiment, the cross-sectional size of the narrow working shaft 7 is 14m×14m, which cannot meet the requirements for transporting small tank cars to pass through the switch. The diameter of the small-diameter tunnel 6 is 3m, which cannot meet the requirements for transporting small tank cars.

[0026] Translating ferry vehicle 1 is composed of car body, small tank car track, driving wheel set, driven wheel set and PLC alignment control system. Translating ferry vehicle 1 is equipped with two sets of tracks, and the distance between adjacent tracks is 762mm. 4 have the same spacing, and the translation ferry car 1 is 10m long and 4.6m wide. The translation direction of the translation shuttle bus 1 is perpendicular to the central axis of the small-diameter tunnel 6, and can realize automatic alignment and manual alignment with the inner track 4 of the tunnel.

[0027] The size of the concrete transport small tanker is determined according to the size of the tunn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com