Firefighting exhaust fan

A smoke exhaust fan and fire-fighting technology, which is applied in the direction of electromechanical devices, mechanical equipment, and control of mechanical energy, can solve problems such as troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

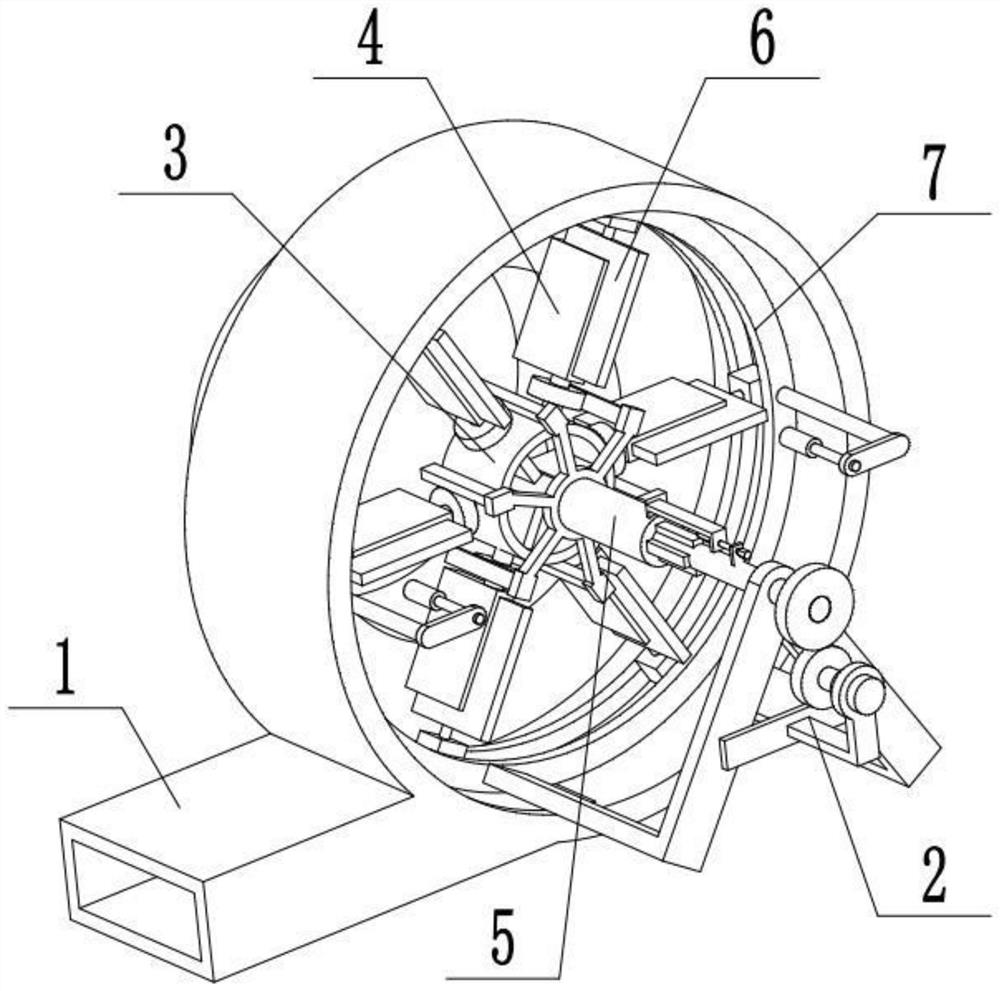

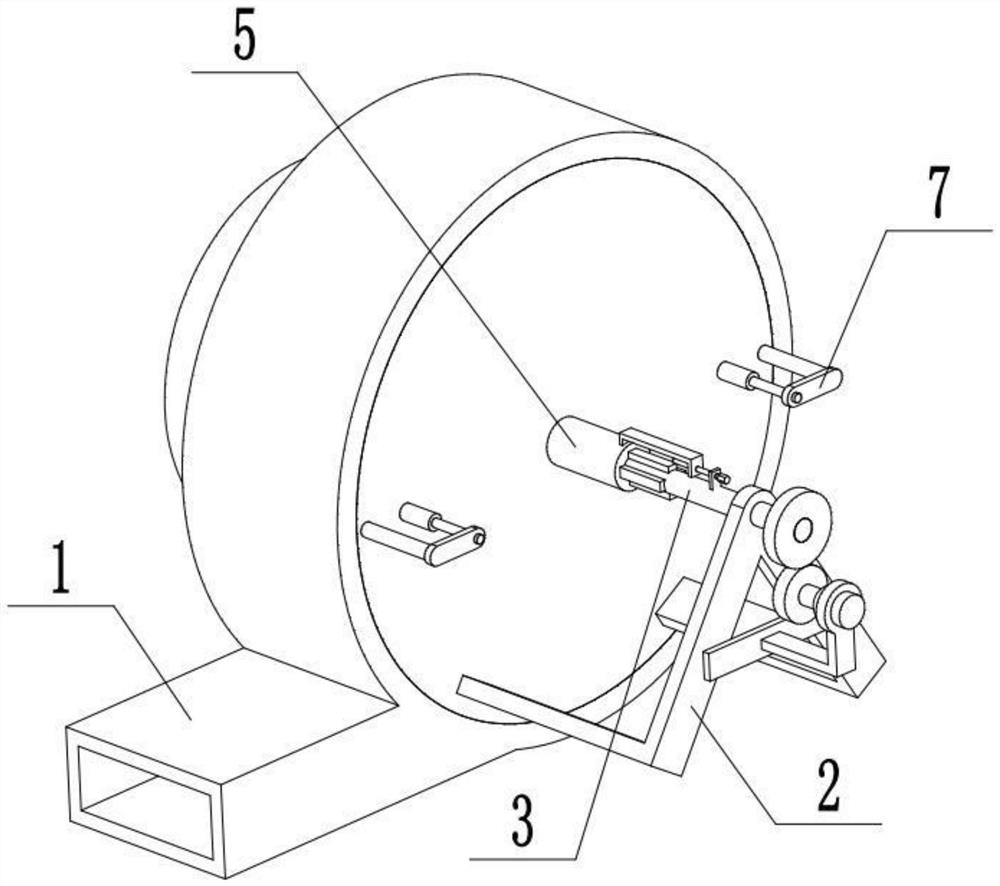

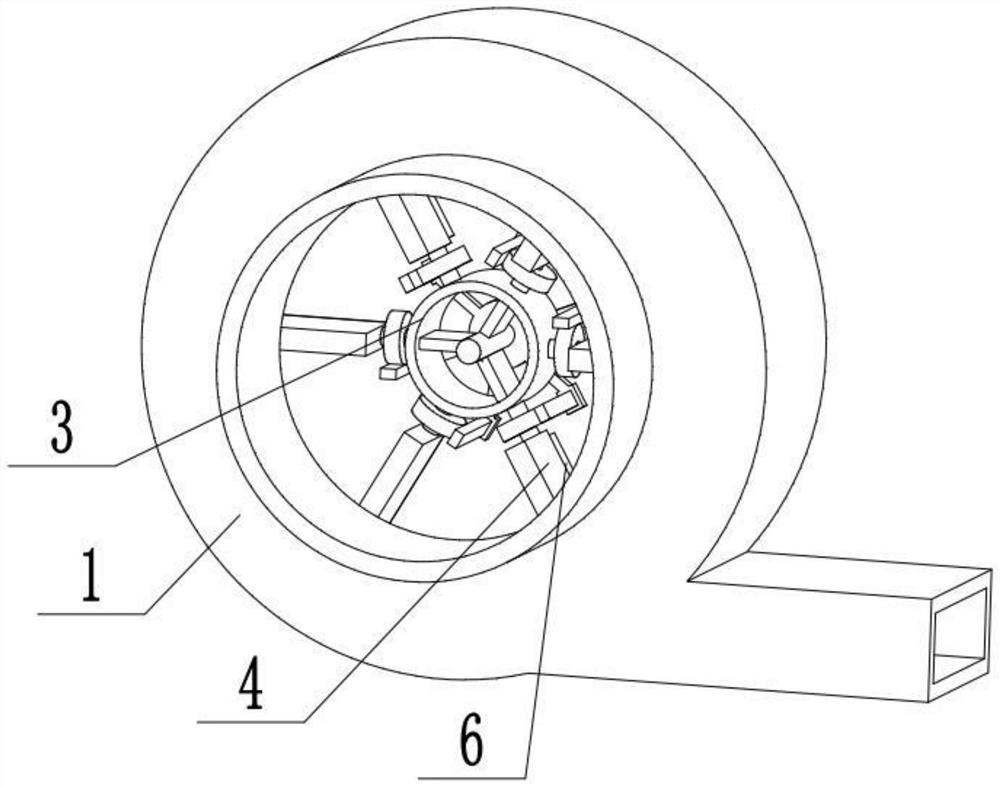

[0027] Combine below Figure 1-7 Describe this embodiment, a fire-fighting smoke exhaust fan, including a housing 1, a driving device 2, a blade rotation control mechanism 3, an inner blade assembly opening 4, an angle adjustment member 5, an outer blade assembly 6, and a telescopic adjustment mechanism 7 , the drive device 2 is fixedly connected to the outer end of the housing 1, one end of the blade rotation control mechanism 3 is connected to the drive device 2, and the other end of the blade rotation control mechanism 3 is located in the housing 1, a plurality of The inner fan blade assembly port 4 is evenly arranged on the fan blade rotation control mechanism 3, and the angle adjustment member 5 is cooperatively connected to the fan blade rotation control mechanism 3, and the angle adjustment member 5 is cooperatively connected with a plurality of inner fan blade assembly ports 4. Each outer blade assembly 6 is movably connected with a plurality of inner blade assembly op...

specific Embodiment approach 2

[0029] Combine below Figure 1-7 To illustrate this embodiment, the housing 1 is provided with an air inlet 1-1, an air outlet 1-2 and a front cover 1-3; one end of the housing 1 is provided with an air inlet 1-1, and the housing 1 The lower end is provided with an air outlet 1-2, the front end of the housing 1 is detachably connected to the front cover 1-3, and the driving device 2 is fixedly connected to the front cover 1-3. When in use, a plurality of inner fan blade assembly ports 4 and a plurality of outer fan blade assemblies 6 rotate to generate negative pressure in the casing 1, and the smoke is sucked into the casing 1 through the air inlet 1-1, and is discharged from the air outlet 1-2. discharge.

specific Embodiment approach 3

[0031] Combine below Figure 1-7Describe this embodiment, described driving device 2 comprises motor 2-1, fixed frame 2-2 and first gear 2-3; Motor 2-1 is fixedly connected on the fixed frame 2-2 by motor frame, -2 is fixedly connected to the front cover plate 1-3, the output shaft of the motor 2-1 is fixedly connected to the first gear 2-3, and the first gear 2-3 is connected with the blade rotation control mechanism 3 in cooperation. When in use, the motor 2-1 starts to drive the first gear 2-3 to rotate, and the first gear 2-3 drives the fan blade rotation control mechanism 3 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com