Vibration isolation bearing pedestal utilizing two-stage vibration isolation technology

A bearing seat and bearing support seat technology, applied in the field of machinery, can solve problems such as hazards and large vibration of components, and achieve the effects of strong integration, convenient maintenance and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

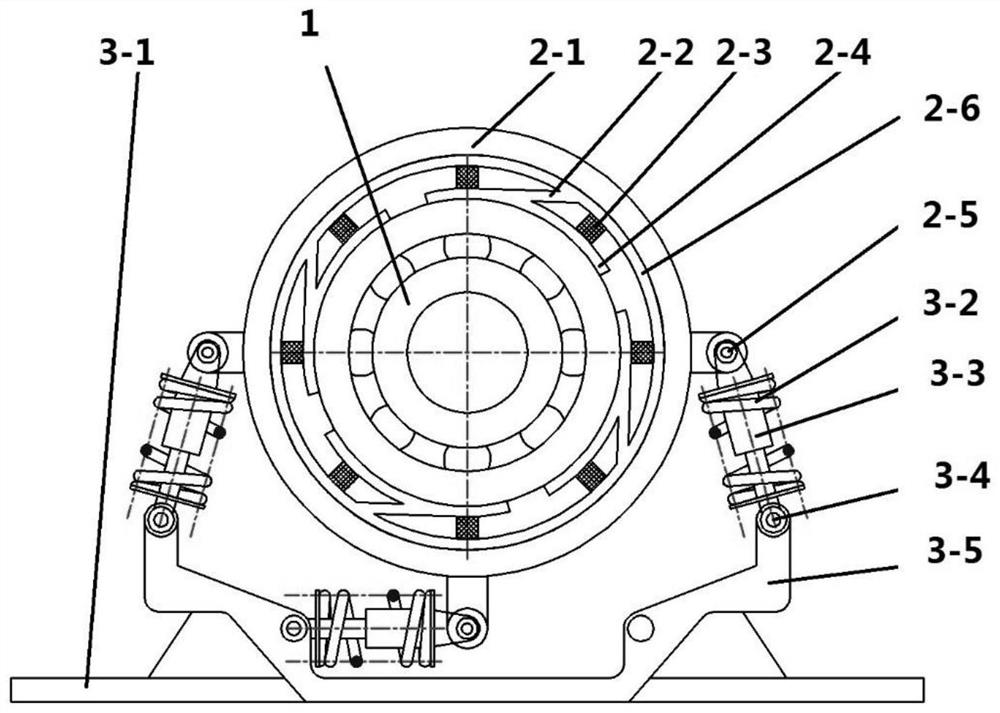

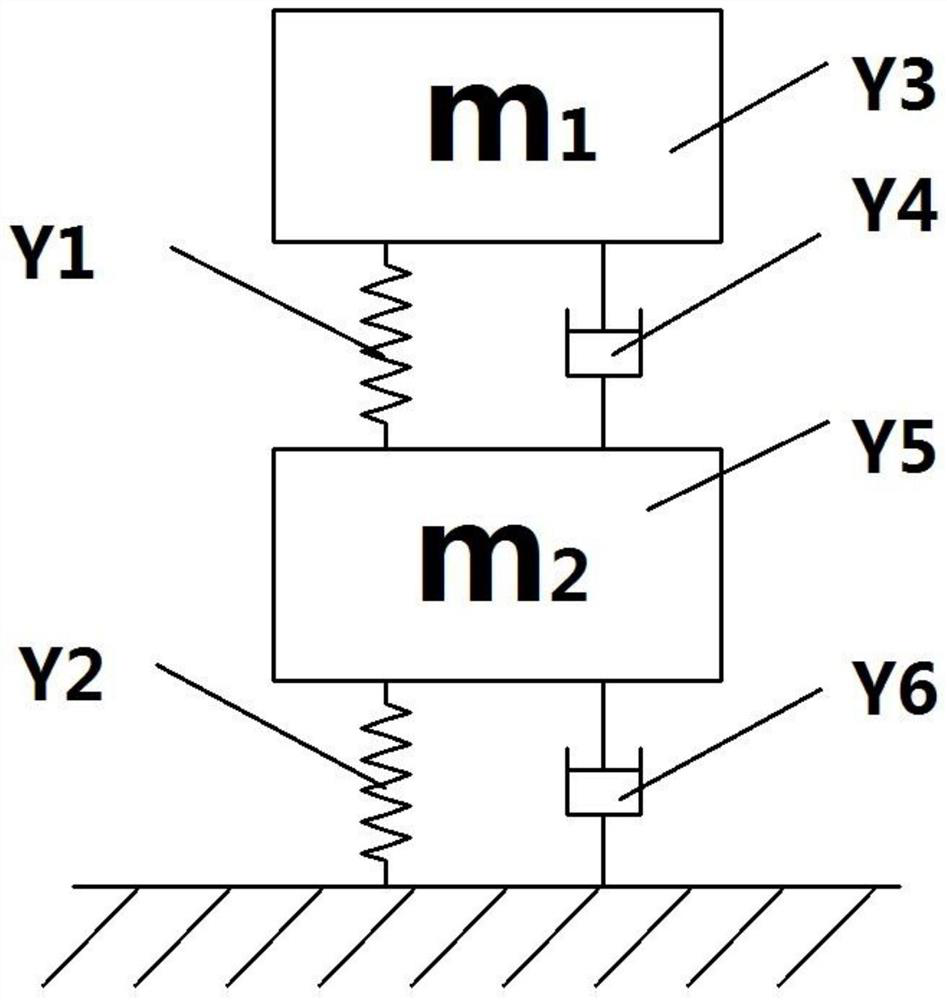

[0031] A vibration isolation bearing seat using secondary vibration isolation technology, such as figure 1 As shown, including the bearing body 1, the bearing fixing ring 2-4, the inner seat fixing ring 2-1 and the base type bearing support seat 3-5, the bearing body 1, the bearing fixing ring 2-4 and the inner seat fixing ring 2-1 is sleeved in order from the inside to the outside, and the bearing fixing ring 2-4 and the inner seat fixing ring 2-1 are connected by a leaf spring 2-2, such as Figure 4 As shown, the structure of the primary leaf spring 2-2 is ring-shaped, the inner wall of the ring is uniformly provided with arc-shaped pieces connected by supporting rods, and the primary damping block 2-3 is bonded between the ring-shaped and the arc-shaped pieces. The inner seat fixing ring 2-1 is provided with connecting ears on both sides and bottom of the circumference, each connecting ear is provided with inner seat fixing ring hinge points 2-5, one end of the secondary damp...

Embodiment 2

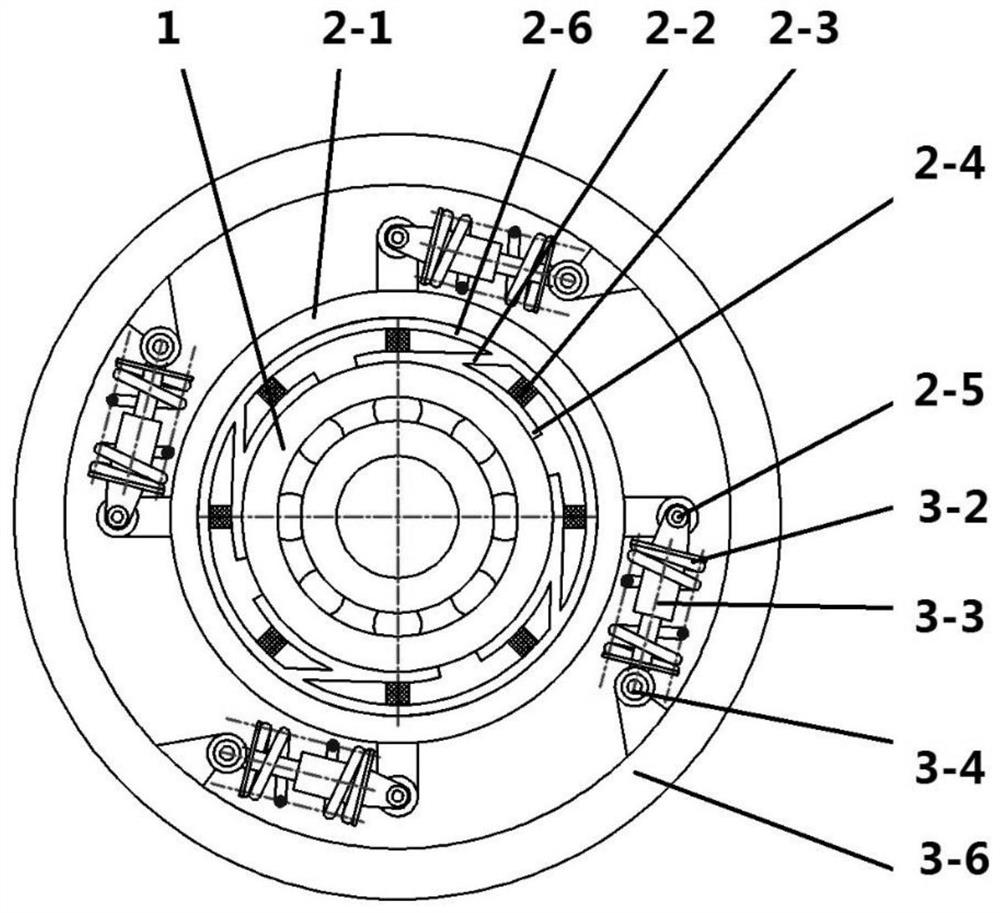

[0034] A vibration isolation bearing seat using secondary vibration isolation technology, such as figure 2 As shown, including the bearing body 1, the bearing fixing ring 2-4, the inner seat fixing ring 2-1 and the circular bearing support seat 3-6, the bearing body 1, the bearing fixing ring 2-4 and the inner seat fixing ring 2-1 is sleeved in order from the inside to the outside, and the bearing fixing ring 2-4 and the inner seat fixing ring 2-1 are connected by a leaf spring 2-2, such as Figure 4 As shown; the structure of the primary leaf spring 2-2 is ring-shaped, the inner wall of the ring is uniformly provided with arc-shaped pieces connected by supporting rods, and the primary damping block 2-3 is bonded between the ring-shaped and the arc-shaped pieces. The inner seat fixing ring 2-1 is provided with 4 connecting ears evenly distributed on the circumference, and each connecting ear is provided with a base hinge point 3-4. One end of the secondary damper 3-3 is hinged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com