Planetary roller screw with decelerating function

A planetary roller and lead screw technology, which is applied to belts/chains/gears, mechanical equipment, transmission devices, etc., can solve problems such as reduced load-carrying capacity, increased wear of screw and rollers, and smaller teeth, and achieves Improve the service life and the effect of reasonable rotation direction design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

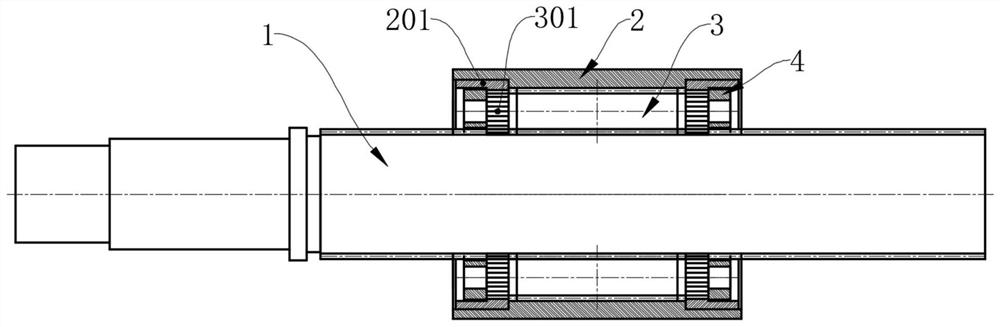

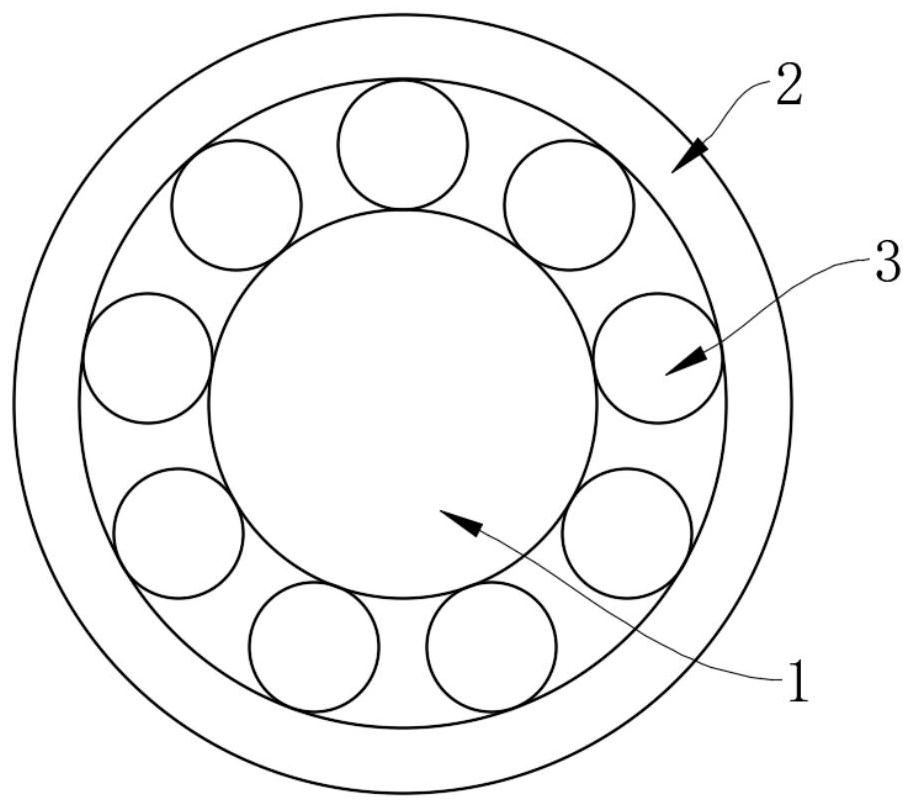

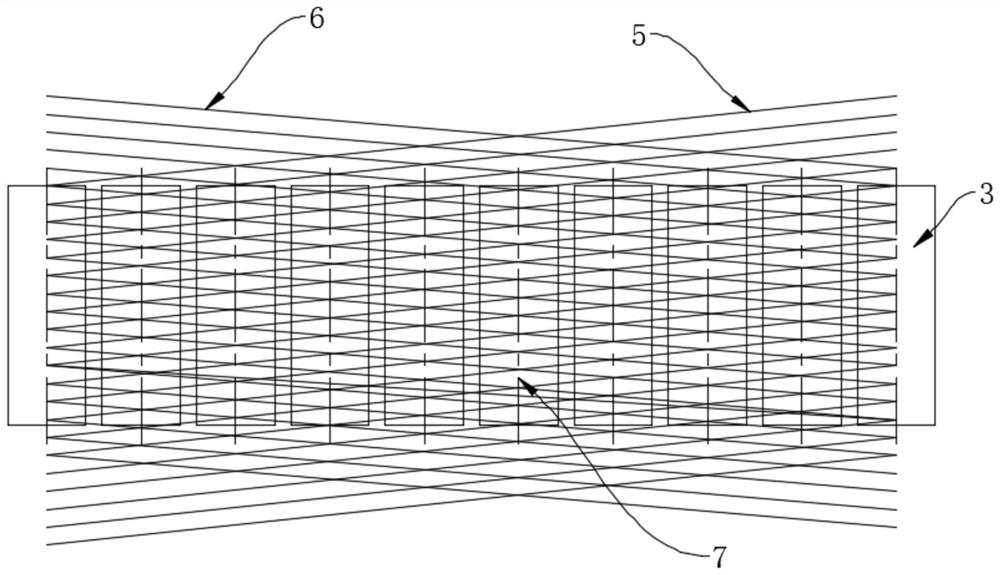

[0021] Such as figure 1 , figure 2 with image 3 As shown, this embodiment provides a planetary roller screw with deceleration function, including a screw 1, a nut 2 and a number of rollers 3 located between the outer circumference of the screw 1 and the inner circumference of the nut 2. The outer periphery is also covered with a cage 4, and the cage 4 is provided with a number of retaining holes, and the rollers 3 are inserted in the retaining holes in a one-to-one correspondence; ring 201, and an external gear 301 meshing with the internal gear 201 is provided at both ends of each roller 3, and the meshing be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com