Allopurinol quality detection method

A quality detection method, the technology of allopurinol, which is applied in the direction of measuring device, transmittance measurement, preparation of test samples, etc., can solve the problems of detection result error, etc., and achieve rapid response, convenient observation, high accuracy and sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

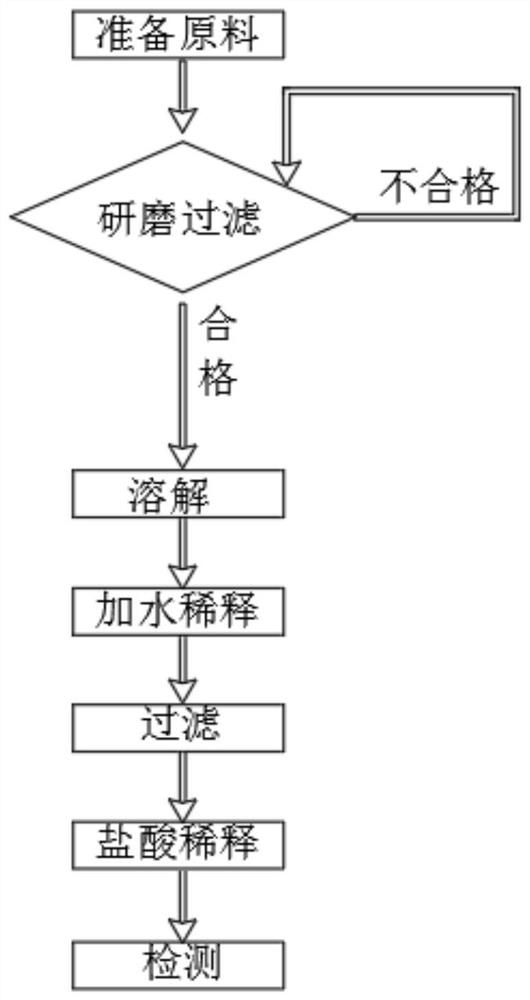

[0030] refer to figure 1 , a kind of allopurinol quality detection method, comprises the following steps:

[0031] S1: Prepare raw materials, 30 allopurinol tablets, balance, sieve, mortar, 100 ml measuring bottle, 30 ml NaOH, 500 ml measuring bottle, 200 ml hydrochloric acid solution, stirring rod;

[0032] S2: Grinding and filtering, taking 20 allopurinol tablets, weighing with a balance, recording the mass, and then grinding with a mortar and filtering with a sieve;

[0033] S3: Dissolve, take the qualified allopurinol tablet powder after filtration and put it into a 100 ml measuring bottle, then add 20 ml of NaOH, stir with a stirring bar to make it fully dissolve, and the allopurinol to be tested can be dissolved by adding NaOH Allopurinol and other related substances, namely impurities, in the alcohol powder sample are effectively separated and detected, with strong operability, strong specificity, high accuracy and high sensitivity of the detection method;

[0034] S4...

Embodiment 2

[0041] refer to figure 1 , a kind of allopurinol quality detection method, comprises the following steps:

[0042] S1: Prepare raw materials, 30 allopurinol tablets, balance, sieve, mortar, 100 ml measuring bottle, 30 ml NaOH, 500 ml measuring bottle, 200 ml hydrochloric acid solution, stirring rod;

[0043] S2: Grinding and filtering, taking 20 allopurinol tablets, weighing with a balance, recording the mass, and then grinding with a mortar and filtering with a sieve;

[0044] S3: Dissolve, take the qualified allopurinol tablet powder after filtration and put it into a 100 ml measuring bottle, then add 20 ml of NaOH, stir with a stirring bar to make it fully dissolve, and the allopurinol to be tested can be dissolved by adding NaOH Allopurinol and other related substances, namely impurities, in the alcohol powder sample are effectively separated and detected, with strong operability, strong specificity, high accuracy and high sensitivity of the detection method;

[0045] S4...

Embodiment 3

[0052] refer to figure 1 , a kind of allopurinol quality detection method, comprises the following steps:

[0053] S1: Prepare raw materials, 30 allopurinol tablets, balance, sieve, mortar, 100 ml measuring bottle, 30 ml NaOH, 1000 ml measuring bottle, 200 ml hydrochloric acid solution, stirring rod;

[0054] S2: Grinding and filtering, taking 40 allopurinol tablets, weighing with a balance, recording the mass, and then grinding with a mortar and filtering with a sieve;

[0055] S3: Dissolve, take the qualified allopurinol tablet powder after filtration and put it into a 100 ml measuring bottle, then add 40 ml of NaOH, stir with a stirring bar to make it fully dissolve, and the allopurinol to be tested can be dissolved by adding NaOH Allopurinol and other related substances, namely impurities, in the alcohol powder sample are effectively separated and detected, with strong operability, strong specificity, high accuracy and high sensitivity of the detection method;

[0056] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com