Whole bean enzyme deactivation method

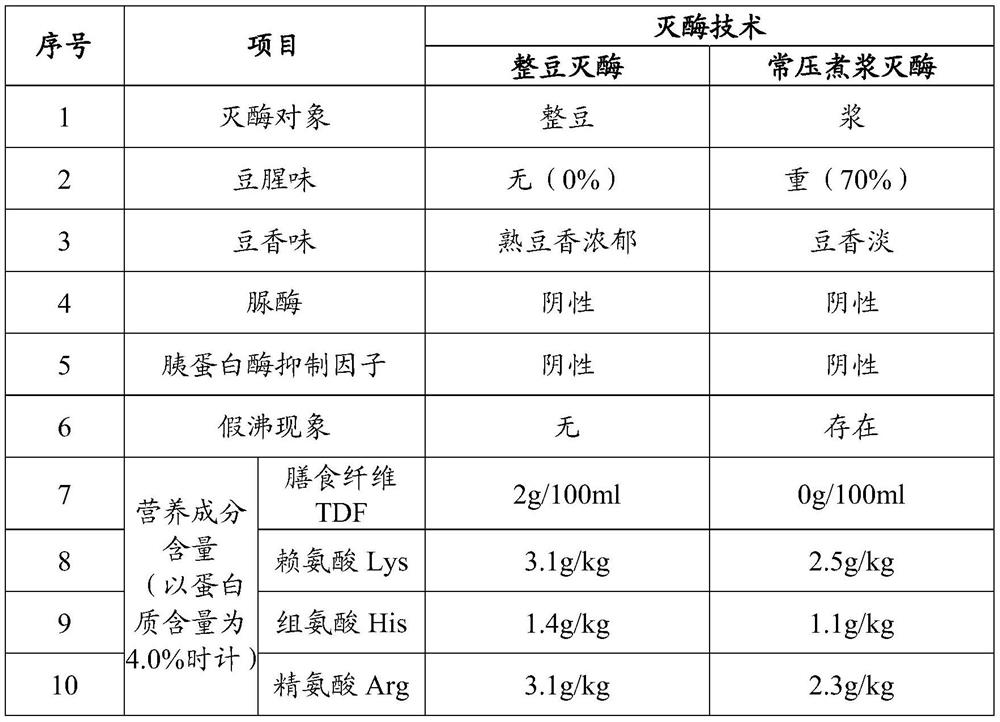

A technology for inactivating enzymes and beans, applied in the direction of food science, etc., can solve the problems of lack of aroma of cooked beans, inability to completely remove beany smell, and general flavor feedback from consumers, so as to achieve uniform heating and eliminate bad flavors such as beany smell The effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

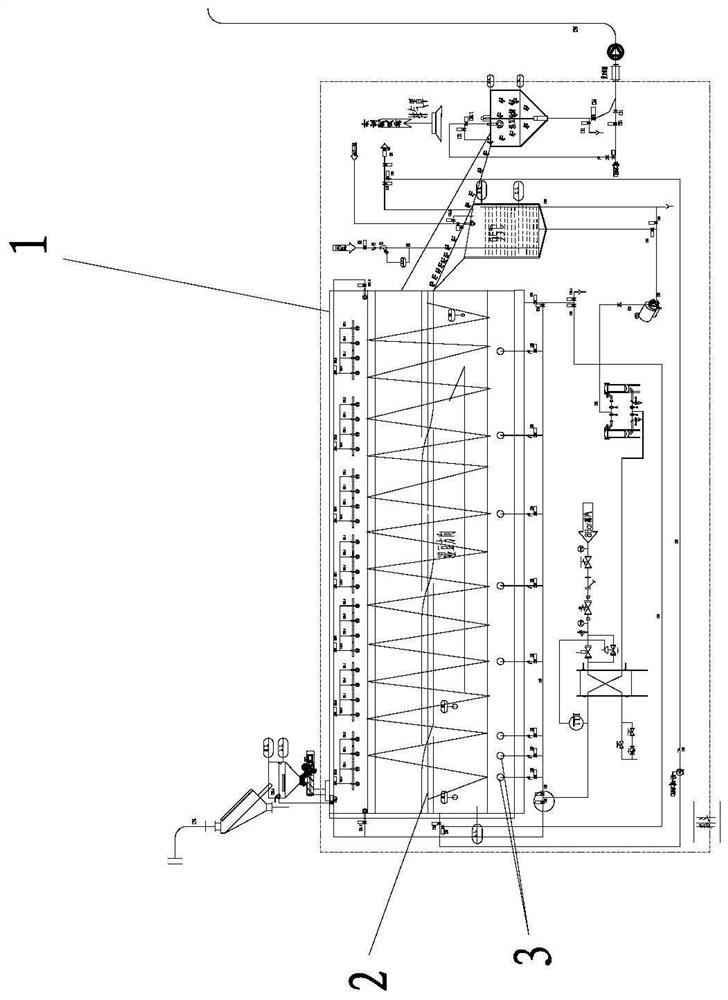

Image

Examples

Embodiment Construction

[0016] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0017] 1. Enzyme inactivation method

[0018] A method for inactivating enzymes in whole beans, comprising the following steps: transferring soaked beans to the feed end of an enzyme inactivating device, controlling the temperature for inactivating enzymes at 93-98°C, and propulsing the beans in a screw; The beans are sprayed with water at 93-98°C until they are suspended and tossed, and the enzymes are continuously propelled for 15-20 minutes before they are output from the discharge end of the enzyme-inactivating device.

[0019] The above-mentioned beans can be soybeans, black beans or green beans.

[0020] The method for killing enzymes in whole beans of the present invention, when killing enzymes, the spiral continuous propulsion is combined with spray flushing, so that the beans can be suspended and toss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com