Disassembling and destroying head and disassembling and destroying device for medical waste syringes

A technology for destroying devices and syringes, which is applied to hypodermic instruments, needles, and instruments introduced into the body, etc., can solve the problems of needle stabbing staff, increasing needles, and inability to separate the syringe needle from the syringe barrel, thereby reducing needle tip injuries. Human probability, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

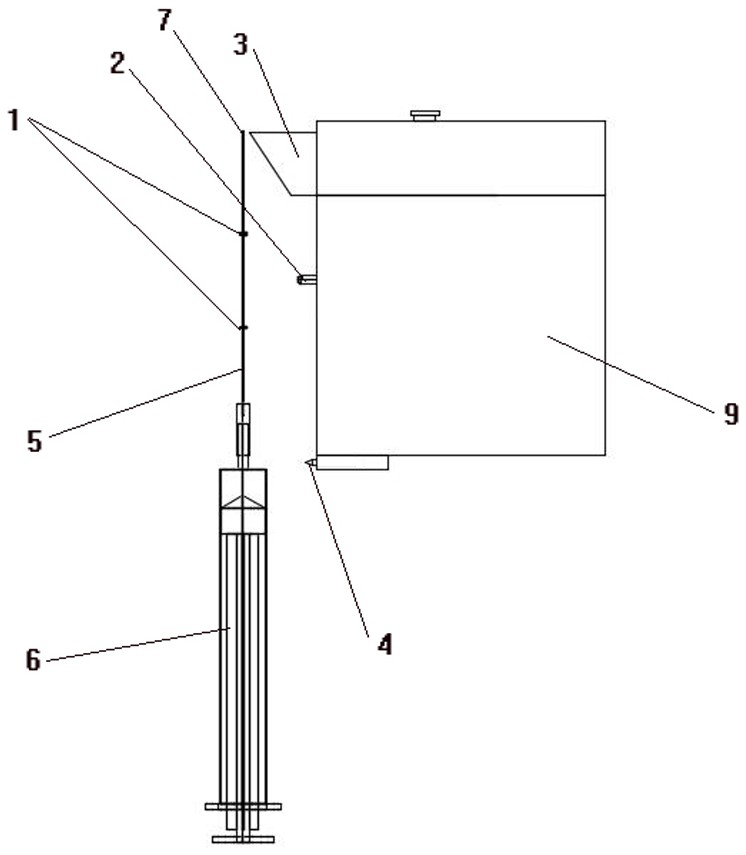

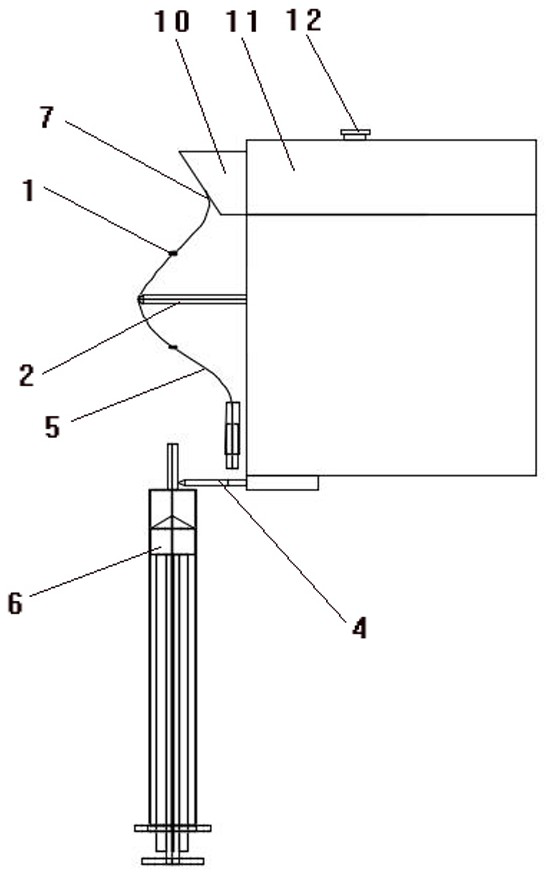

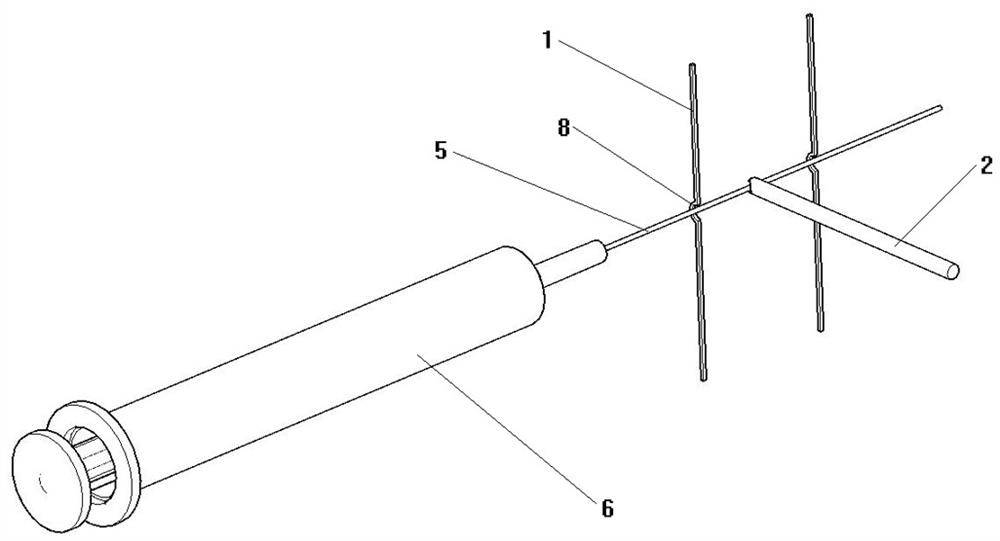

[0045] As shown in the figure: a dismantling and destroying head of a medical waste syringe, including two limit posts 1 arranged side by side, a ram 2 used to force the straight rod part of the needle 5 to bend and deform, and a ram 2 to drive the ram 2 to reciprocate The driving device is used to force the needle tip 7 of the needle 5 to bend and deform the plug 3 and the dismantling lever 4 for separating the needle 5 from the syringe 6. The head end of the dismantling lever 4 is provided with a cuttable needle 5 and the syringe 6 blades at the junction.

[0046] The lance 2 is arranged perpendicular to the plane where the two limiting posts 1 are located. In the initial state, there is a gap between the head end of the lance 2 and the plane where the two limiting posts 1 are located for the needle 5 to be folded to pass through. The head end of the lance 2 is provided with a slot that can hold the straight part of the needle 5, and the lance 2 can reciprocate along its axi...

Embodiment 2

[0054] A device for dismantling and destroying medical waste syringes, comprising a syringe dismantling and destroying mechanism and a waste material collecting mechanism.

[0055] The syringe dismantling and destroying mechanism includes a feeding chute assembly and the dismantling and destroying head described in Embodiment 1 arranged below the feeding chute. The syringe disassembly and destruction mechanism is the core mechanism of the device, and its main function is to realize the disassembly and separation of the needle 5 and the syringe 6 and the bending of the needle 5 and the bending of the needle tip 7 . The function of the feeding chute assembly is to deliver the waste syringes to be processed to the syringe dismantling and destroying mechanism.

[0056] The feeding chute assembly includes a lower hopper 13 , a vertical storage channel 14 and a material shifter, and the vertical storage channel 14 is arranged below the lower hopper 13 .

[0057] The device also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com