Stone crushing device for exploiting rare earth efficiently

A crushing device and rare earth technology, applied in cleaning methods and utensils, removal of smoke and dust, grain processing, etc., can solve problems such as poor crushing effect of briquette on stones, and achieve rich functions, good dust removal function, and good crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

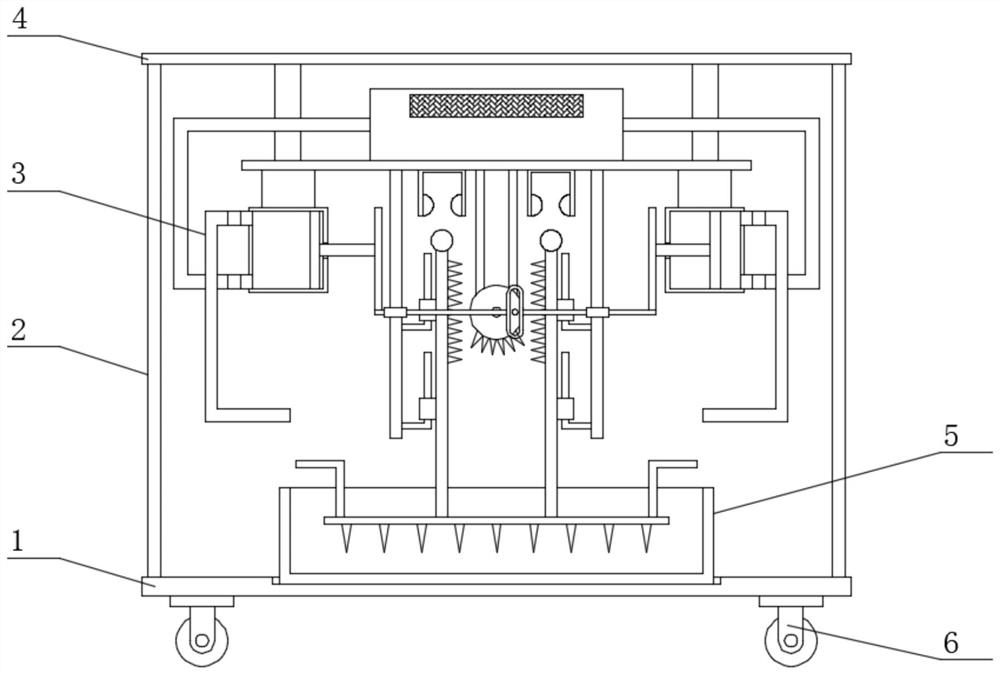

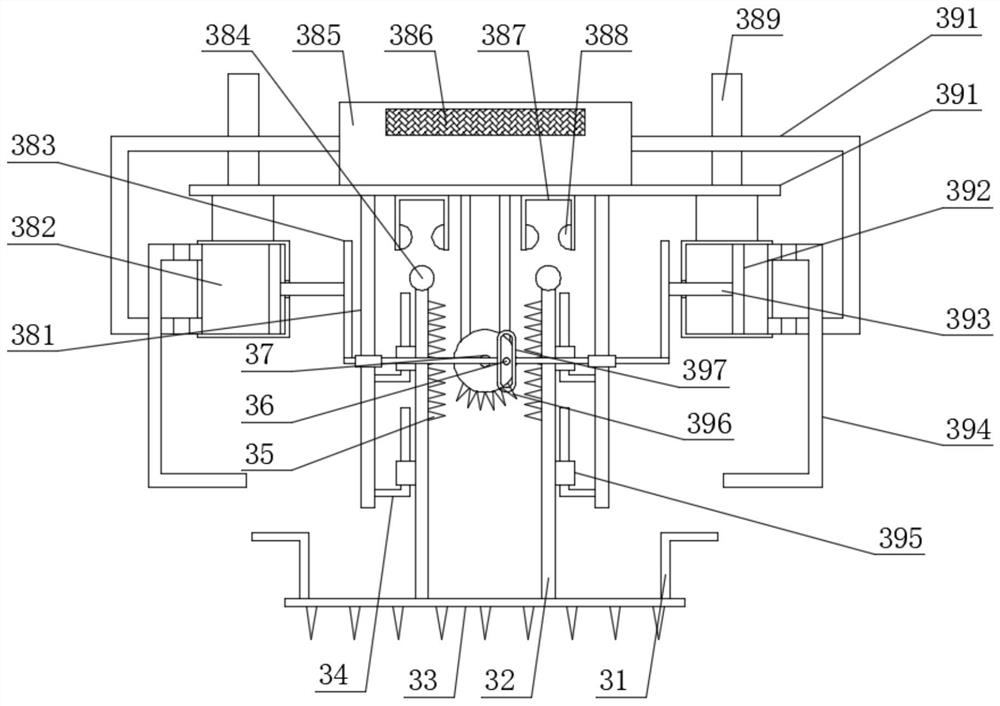

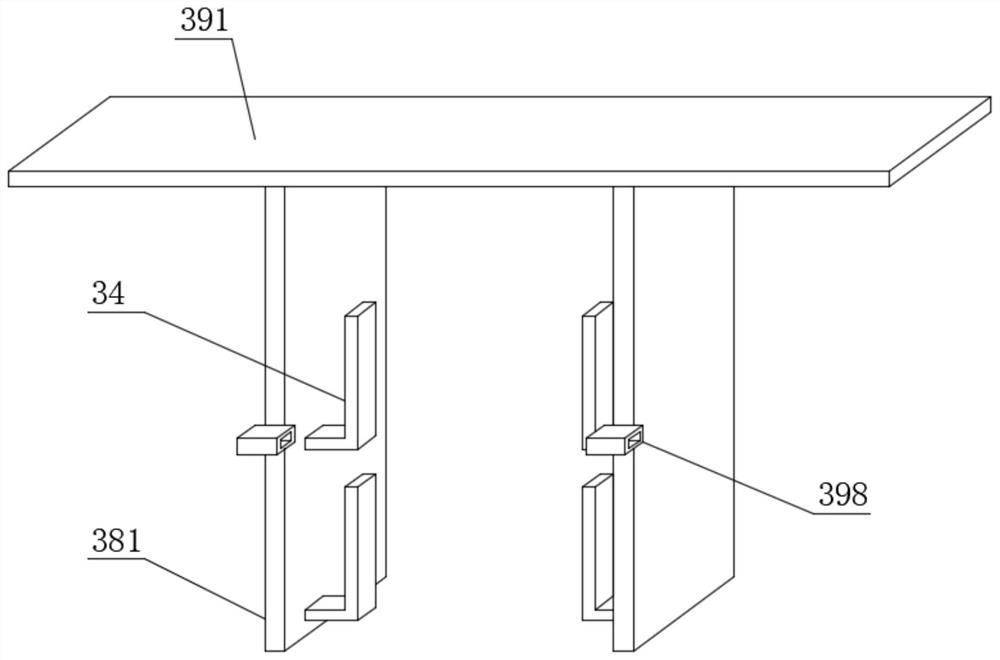

[0024] See Figure 1-Figure 4 , The present invention provides a technical solution: a high-efficiency rare earth stone crushing device, including a first support plate 1, the upper surface of the first support plate 1 is placed with a crushing box 5, the first support plate 1 is provided with The second support plate 4, both ends of the upper surface of the first support plate 1 are welded with side plates 2 corresponding to the second support plate 4, and a crushing mechanism 3 is provided under the second support plate 4. The crushing mechanism 3 includes a third Support plate 391, the connection between the third support plate 391 and the second support plate 4 is welded with a second limit plate 389, a drive motor 37 is welded under the third support plate 391, and drive teeth are welded to the output end of the drive motor 37 Disk 396, a crushing plate 33 is arranged under the drive motor 37, the upper surface of the crushing plate 33 is provided with a first transmission...

Embodiment 2

[0030] On the basis of embodiment 1, in order to enrich the functions of the crushing device, in this embodiment, preferably, the lower surface of the third support plate 391 is further welded with a dust removal cylinder 382 at both ends, and the dust removal cylinder 382 is provided with a piston. 392. One end of the dust removal cylinder 382 is slidably connected with a third transmission plate 393 corresponding to the piston 392, a transmission member 397 is provided on one side of the driving motor 37, and a transmission cylinder 36 corresponding to the transmission member 397 is provided on the driving motor 37 , The bottom end of the first limiting plate 381 is welded with a second limiting sleeve 398 slidably connected to the transmission member 397, and the two ends of the transmission member 397 are provided with a second transmission plate 383 corresponding to the third transmission plate 393, One end of the dust removal cylinder 382 is provided with a dust removal ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com