Sawdust recycling equipment

A technology for recycling equipment and wood chips, which is applied in the direction of lighting and heating equipment, wet separation, cleaning methods and appliances, etc., can solve the problems of wood chips recycling without purification treatment, etc., achieve reduced manpower, good treatment effect, and improved cleaning effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

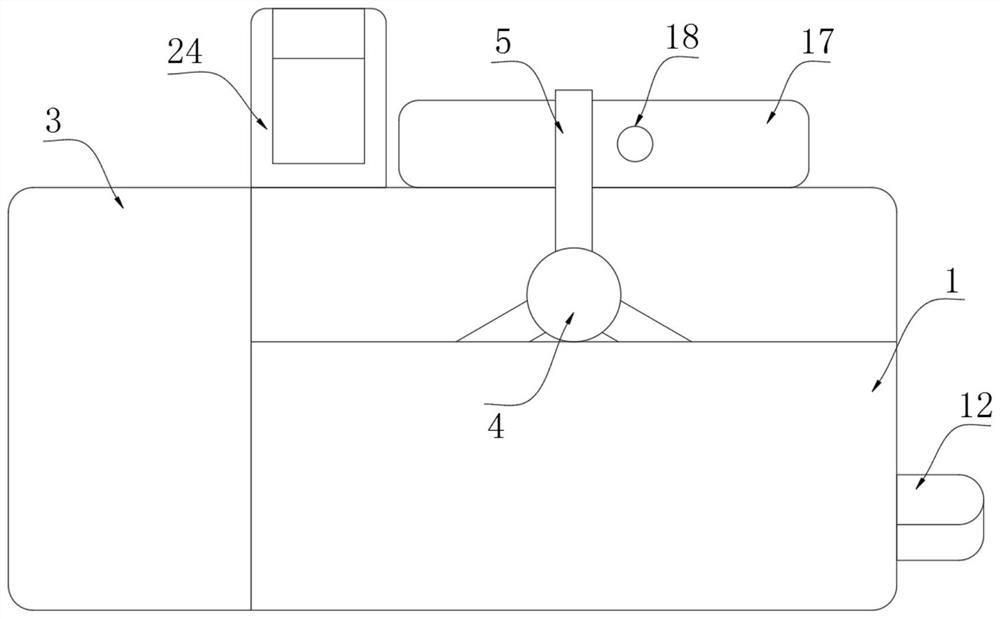

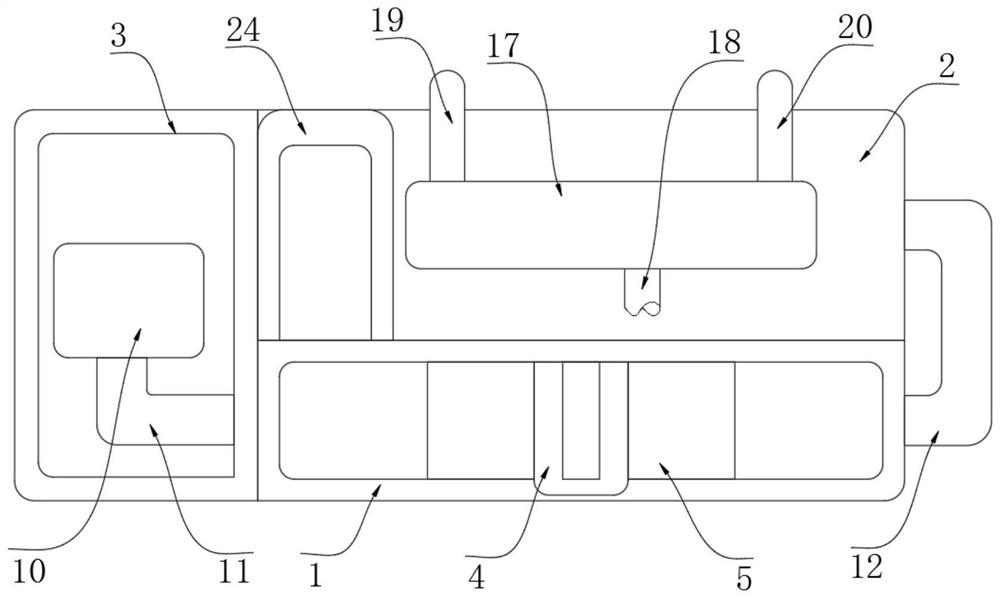

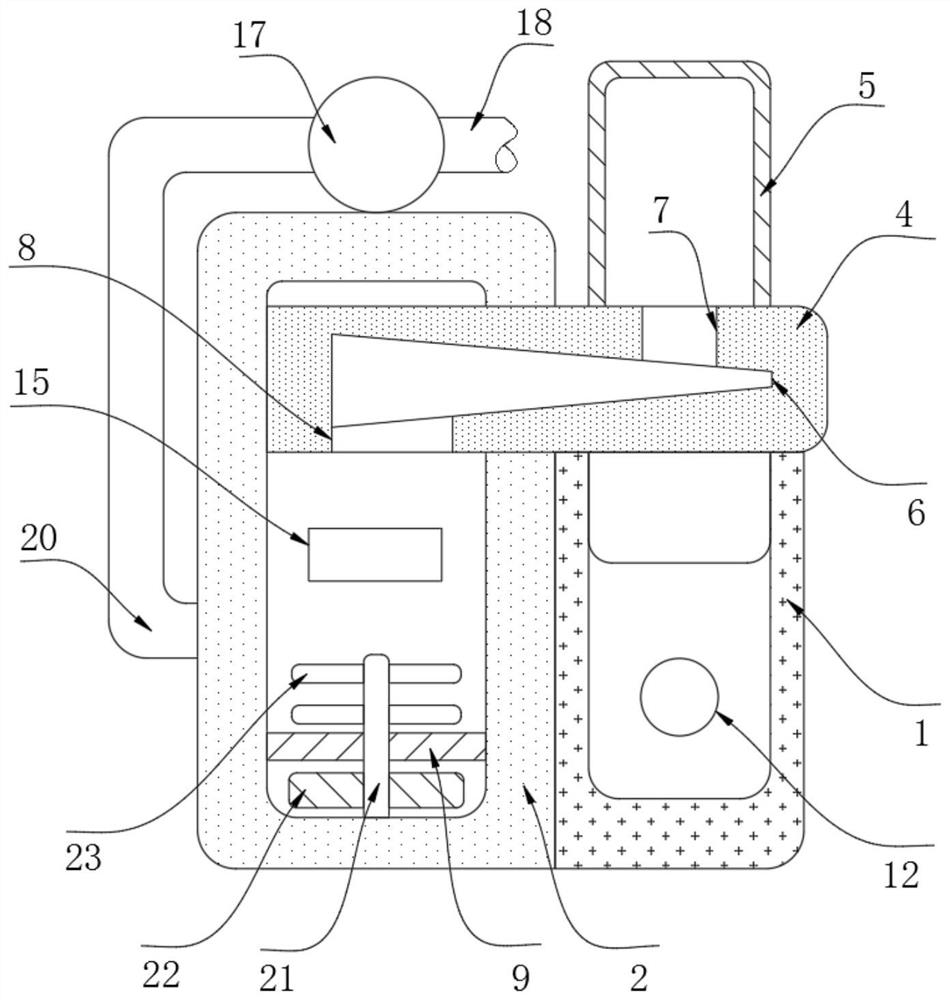

[0023] refer to Figure 1-6 , a kind of sawdust recycling equipment, comprising a cleaning box 1, a drying box 2 and a pump water box 3, the inner wall of the drying box 2 is connected with a main shaft 4 for rotation, and a plurality of catch plates 5 are fixed on the circumferential outer wall of the main shaft 4, and the inside of the main shaft 4 A diversion cavity 6 is provided, and the inner surface of the diversion cavity 6 is inclined to facilitate the flow of wood chips into the drying box 2. The outer wall of the main shaft 4 is provided with a plurality of catch plates 5 corresponding to each other and communicating with the diversion cavity 6. The feed port 7, the capture plate 5 is a mesh plate, the side wall of the capture plate 5 is slidingly connected with the inner wall of the cleaning box 1, so as to ensure the effective capture of wood chips, the water flow can pass through the capture plate 5, and the inner wall of the diversion chamber 6 is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com