Thin wall type bogie skirtboard aluminum profile processing universal tooling

A technology for processing aluminum profiles and bogies, which is applied in the direction of bogies, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reducing processing efficiency, gnawing knives, wasting mold changing time, etc., so as to ensure processing quality and reduce searching Positive time, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

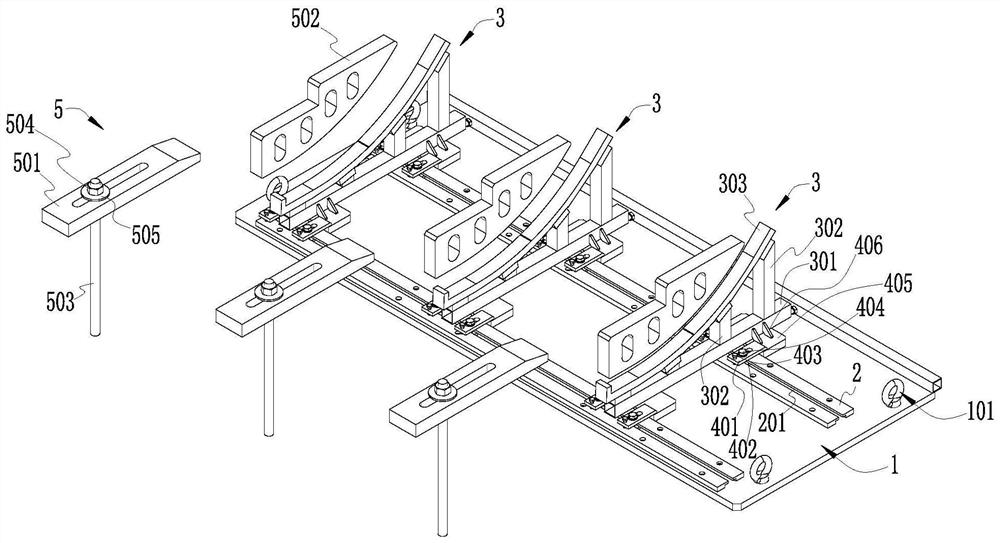

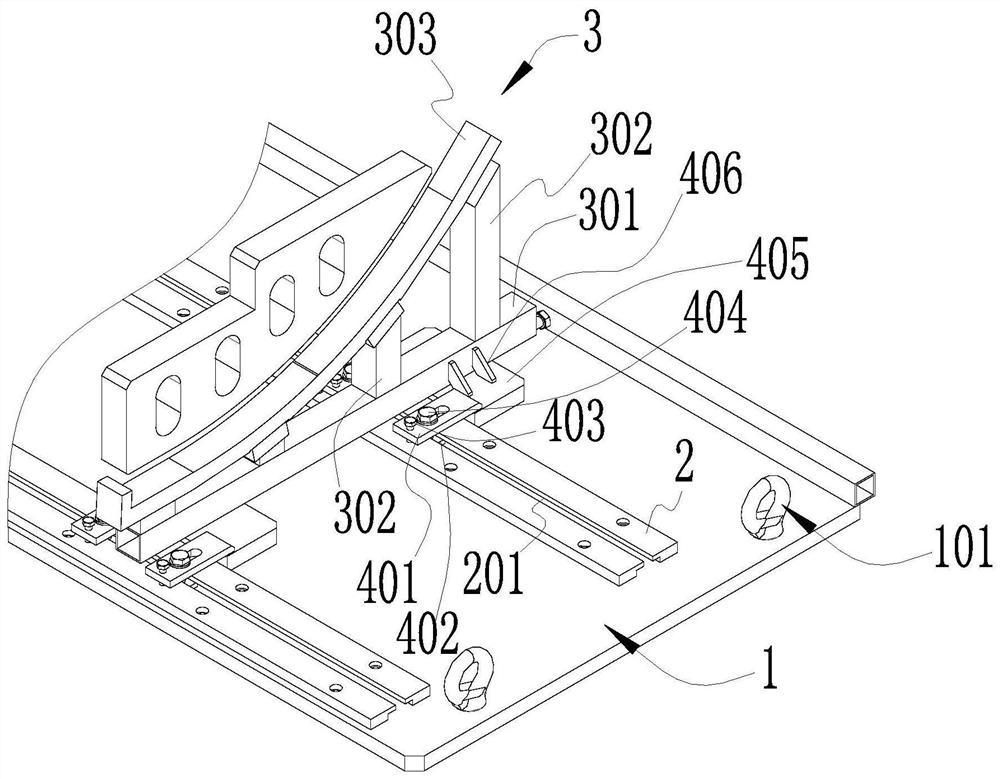

[0061] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0062] see Figure 2 to Figure 5 shown;

[0063]The general tooling for processing thin-walled bogie skirt plate aluminum profiles of the present invention, the tooling includes:

[0064] bottom plate 1;

[0065] A positioning bar 2 extending along the length direction of the bottom plate 1 and fixedly connected to the bottom plate 1, the positioning bar 2 is formed with a positioning chute 201 along its extending direction;

[0066] bogie skirt outer surface support positioning mechanism; and

[0067] Bogie skirt plate inner surface pressing and positioning mechanism;

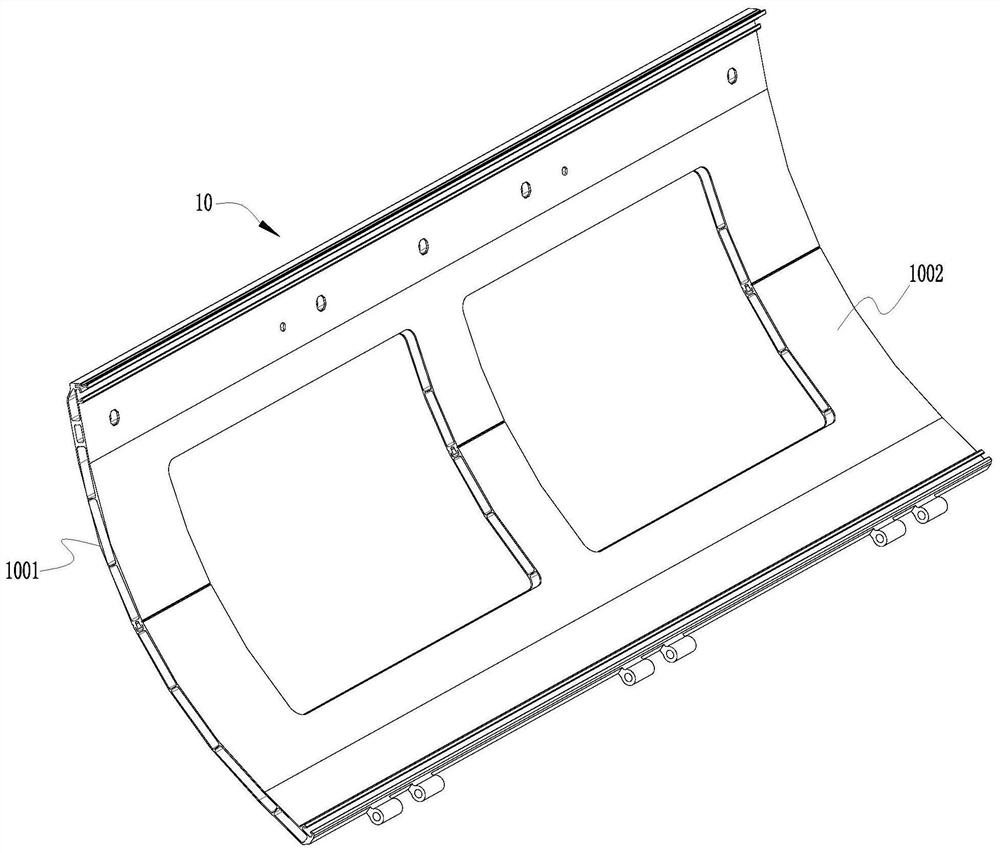

[0068] The support and positioning mechanism for the outer surface of the bogie skirt has a first nylon spacer 303 that is in contact with the outer surface 1001 of the bogie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com