Novel fabricated beam joint and construction form thereof

A prefabricated and new type of technology, applied in the direction of building types, protected buildings/shelters, building components, etc., can solve the problems of lack of multiple connection protection means, single interface connection means, lack of technology, etc., to achieve healthy development promotion, High strength, stable and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. All other embodiments obtained by relevant professionals without making an inventive step belong to the protection scope of the present invention.

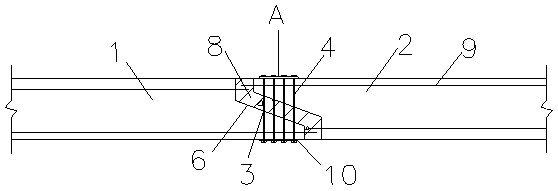

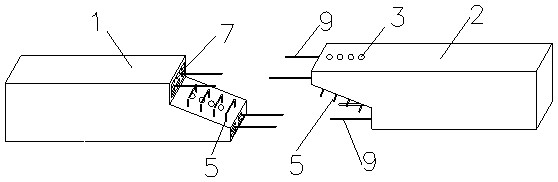

[0033] see Figure 1-4 , the present invention provides a technical solution: a new prefabricated beam joint, including prefabricated main beam 1, prefabricated main beam 2 and cast-in-situ ultra-high performance concrete UHPC8, prefabricated main beam 1 is reserved at the bottom of the beam and at the slope 6 There are bolt holes 3, and the bolt holes 3 run through the upper and lower holes inside the prefabricated main beam 1, and anchors 10 are left on the surface of the beam for supporting use. U-shaped st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com