Tunnel construction process

A tunnel construction and technology technology, applied in tunnels, tunnel linings, tracks, etc., can solve the problems of not considering the stability of the piston cylinder, unbalanced center of gravity, large volume, etc., to achieve both stability and economy, improve stability, The effect of a large execution area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

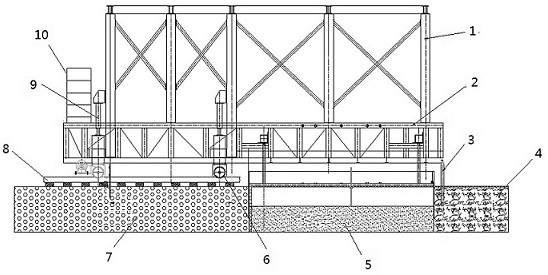

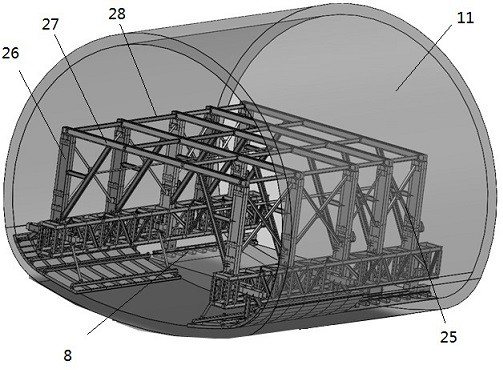

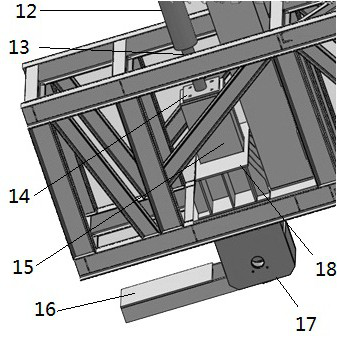

[0042] As shown in the figure: a tunnel construction process, using an inverted arch trolley for construction, the inverted arch trolley includes a door frame, a main beam, a supporting screw, a track running mechanism, a track, a jacking cylinder assembly, and a counterweight , template; wherein the jacking cylinder assembly includes a cylinder, a piston rod, a connecting piece, a first cylinder block, a second cylinder block, a foot, a leg, and a connecting block; the track includes a guide rib, and the track running mechanism It includes a short guide piece and a long guide piece. The short guide piece includes a guide round block and a slant guide plate; the door frame includes inclined beams, vertical beams, cross beams, and longitudinal beams; process, pouring process;

[0043] The preparatory process includes: first, making the inverted arch trolley in place, and checking the size of the trolley and the size of the tunnel; secondly, cleaning the tunnel base and leveling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com