Inhaul cable corrosion monitoring sensor, monitoring equipment and monitoring method

A corrosion monitoring and sensor technology, applied in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve problems such as cable corrosion and aggravate cable corrosion speed, so as to ensure safe operation, clear monitoring principle, and easy The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

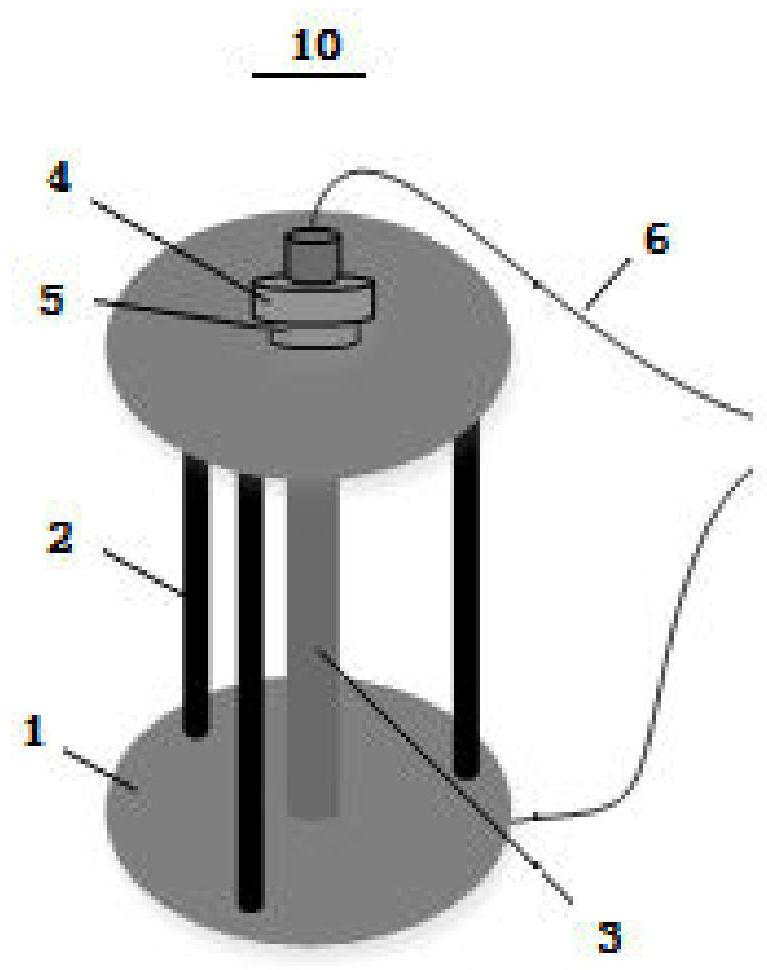

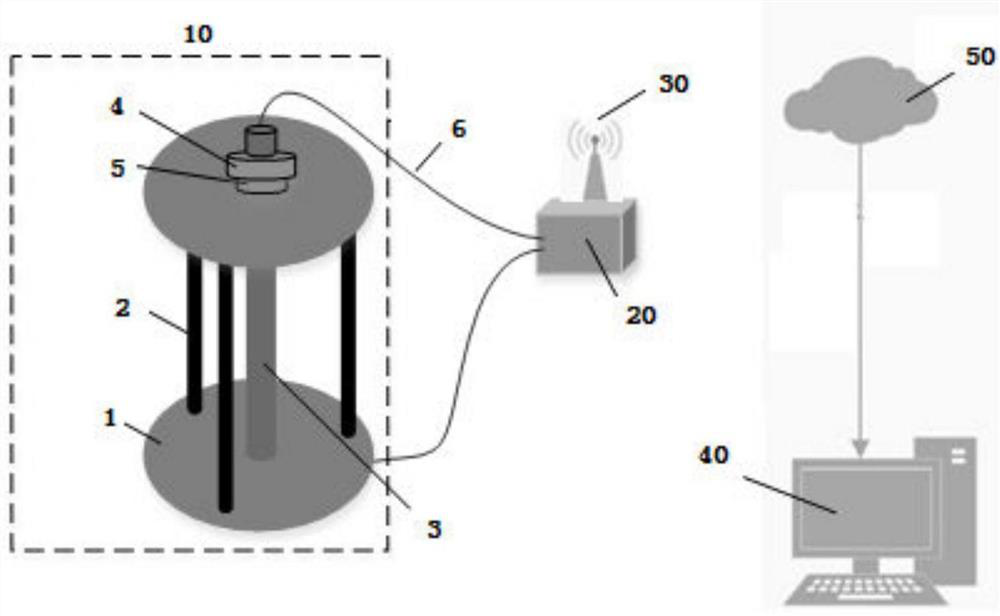

[0029] see figure 1 , In a preferred embodiment of the present invention, a cable corrosion monitoring sensor includes two bases 1 , support columns 2 , probes 3 , pressure rings 5 , anchor heads 4 , and two transmission lines 6 . The two bases 1 are facing and arranged at intervals, and the two are connected by a support column 2. The probe 3 is pierced through the two bases 1 at the same time. One end is stuck on the outside of the two bases 1, the other end is fixed by the anchor head 4, and the pressure ring 5 is installed between the anchor head 4 and the base 1 for measuring the prestress applied on the probe 3 Size, two transmission lines 6 are respectively installed at both ends of the probe 3, one end of the transmission line 6 is connected to the probe 3, and the other end is used to connect to the acquisition instrument 20 outside.

[0030] Preferably, the base 1, the pressure ring 5, the support column 2, and the anchor head 4 are all made of corrosion-resistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com