Microbiological process for the preparation of amides

A technology of microbiology and microbial strains, applied in the field of amide preparation, which can solve problems such as inability to apply chemically specific substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

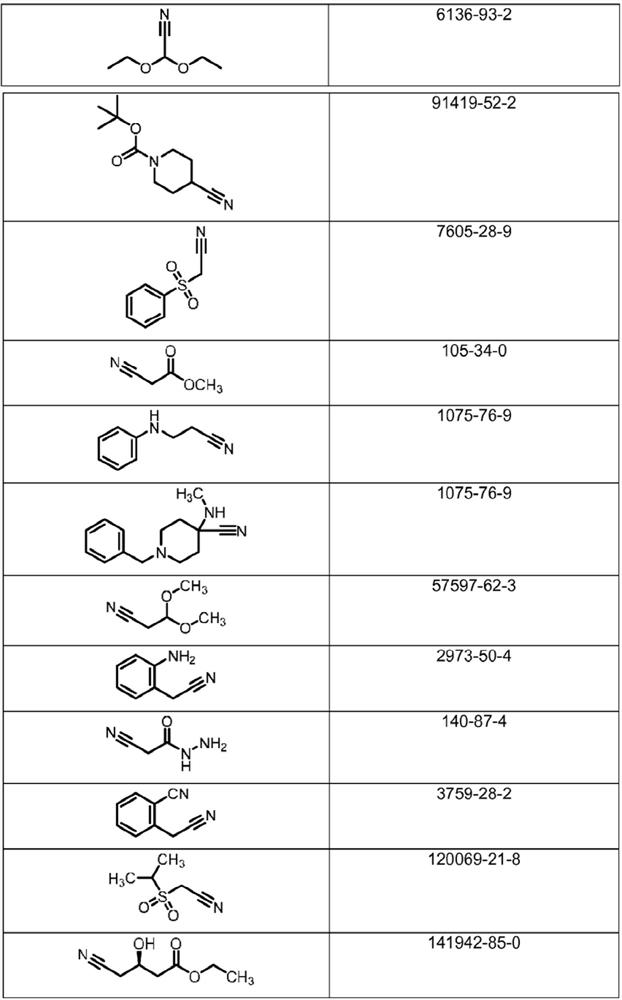

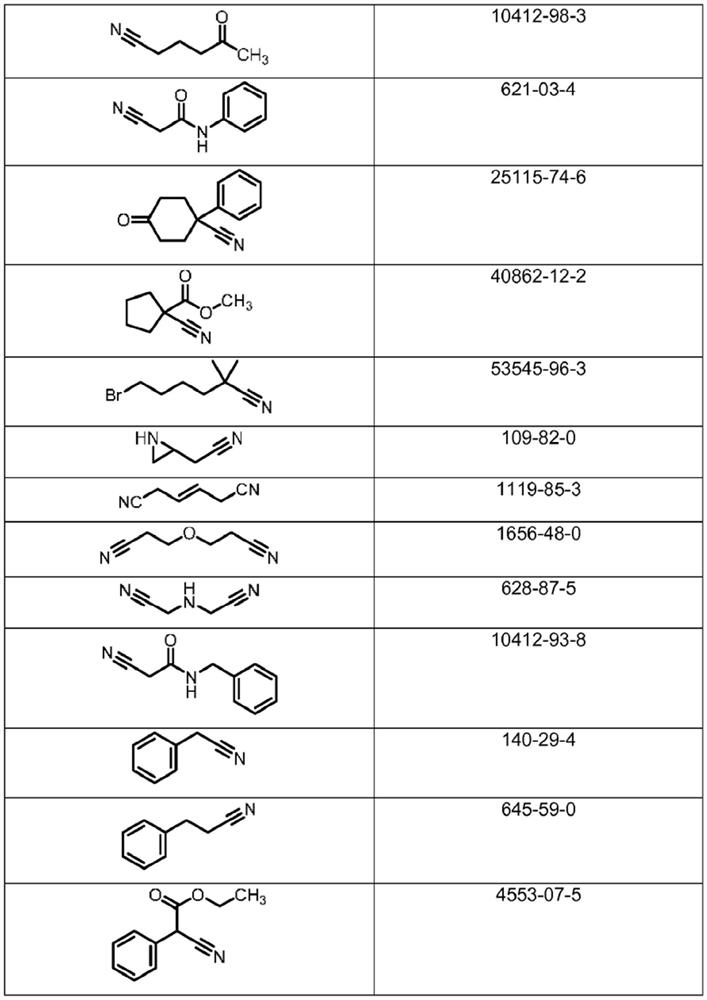

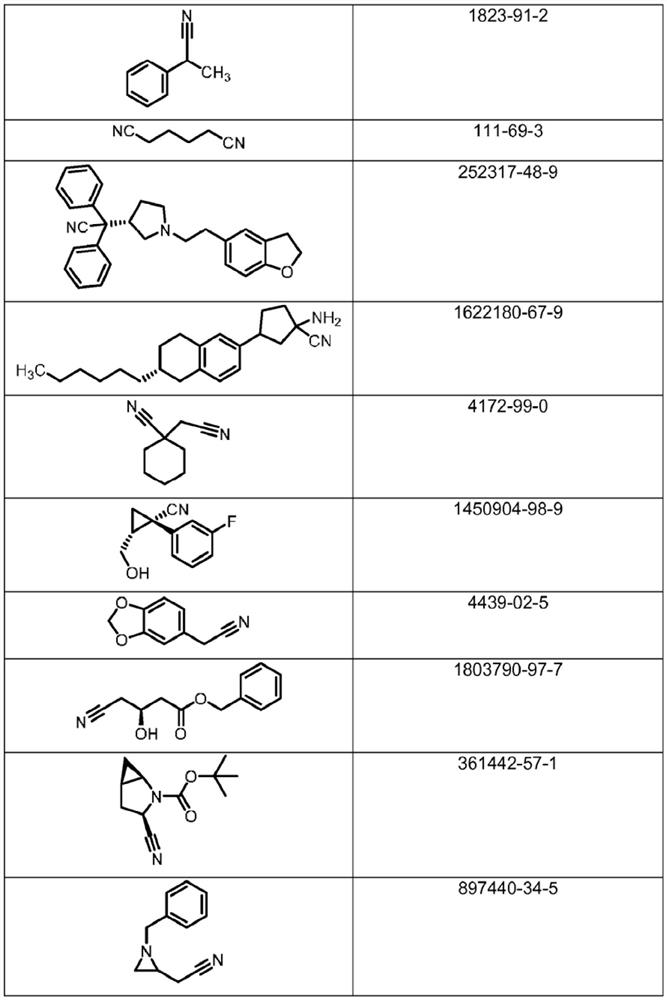

Image

Examples

Embodiment 1

[0063] 2-Chloroacetamide

[0064] NHase was ground in a mortar and added to potassium phosphate buffer (10 mM, pH=7.4) (9 mL) in a 50 mL Erlenmeyer flask. The suspension was mixed by vortexing, and 2-chloroacetonitrile (38 mg, 0.5 mmol) was added to the suspension dissolved in MeOH (1 mL). The reaction was stirred by rotary shaking at 25°C and 250 rpm. After the reaction 1 H-NMR. Samples (1 mL) were analyzed after 1.5, 2.5, 4 and 7 hours. The sample was mixed with MeOH (2 mL), filtered and evaporated under vacuum. After 1.5 hours, complete conversion to 2-chloroacetamide was observed.

[0065] 1 H-NMR (CD 3 OD, 300.13MHz): 4.05-4.83 (s, 2H), comparable to commercially available 2-chloroacetamide samples.

Embodiment 2

[0067] 2,2-diethoxyacetamide

[0068] NHase was ground in a mortar and added to potassium phosphate buffer (10 mM, pH=7.4) (9 mL) in a 50 mL Erlenmeyer flask. The suspension was mixed by vortexing, and 2,2-diethoxyacetonitrile (65 mg, 0.5 mmol) was added to the suspension dissolved in MeOH (1 mL). The reaction was stirred by rotary shaking at 25°C and 250 rpm. After the reaction 1 H-NMR. Samples (1 mL) were analyzed after 1.5, 2.5, 4 and 7 hours. The sample was mixed with MeOH (2 mL), filtered and evaporated under vacuum. After 1.5 hours, complete conversion to 2,2-diethoxyacetamide was observed.

[0069] 1 H-NMR (CD 3 OD, 300.13MHz): 1.44(t, 6H, 3 J HH =6.0Hz), 3.61-3.70 (m, 4H), 4.81 (s, 1H), comparable to commercially available 2,2-diethoxyacetamide samples.

Embodiment 3

[0071] tert-Butyl 4-carbamoylpiperidine-1-carboxylate

[0072] NHase was ground in a mortar and added to potassium phosphate buffer (10 mM, pH=7.4) (9 mL) in a 50 mL Erlenmeyer flask. The suspension was mixed by vortexing, and tert-butyl 4-cyanopiperidine-1-carboxylate (105 mg, 0.5 mmol) was added to the suspension dissolved in MeOH (1 mL). The reaction was stirred by rotary shaking at 25°C and 250 rpm. HPLC-MS was performed after the reaction. Samples (1 mL) were analyzed after 1.5, 2.5, 4 and 7 hours. Samples were mixed with MeOH (2 mL), filtered and injected directly into HPLC. After 7 hours, 40% conversion to tert-butyl 4-carbamoylpiperidine-1-carboxylate was observed.

[0073] MS (ES + ): m / z: 173.0 [M-55]. MS (ES - ): m / z: 227.0 [M-1].

[0074] The HPLC chromatogram is comparable to a synthetic sample of tert-butyl 4-carbamoylpiperidine-1-carboxylate. RRT 3 = 1, RRT 3a = 0.87.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com