Latex conveying system in production process of special polyvinyl chloride resin and conveying method

A polyvinyl chloride, production process technology, applied in the field of latex delivery system in the production process of special polyvinyl chloride resin, can solve the problems of latex efflux, filter clogging, mechanical seal damage, etc., achieve simple and reliable operation, and prevent local pressure Elevate and improve the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

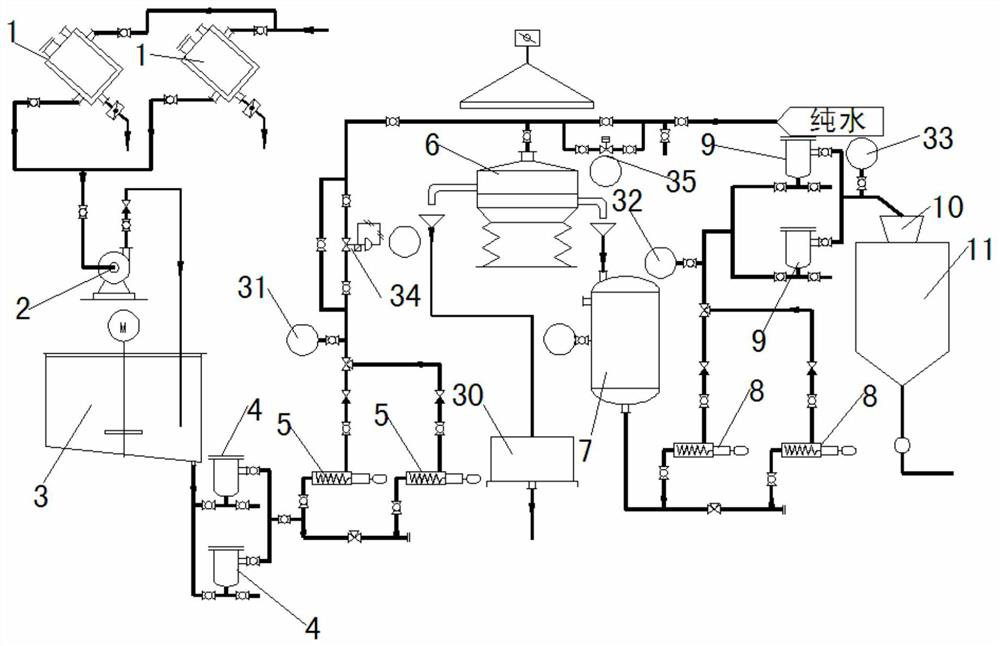

[0059] Polymerization zone A kettle has discharge conditions, open the plunger valve at the bottom of the kettle, and the product latex after polymerization is discharged under pressure (0.4MPaG) to the discharge filter 1 through the discharge pipeline at the bottom of the kettle, and the discharge time is 27min. The volume is 28.5m 3 , after the current of the discharge pump 2 drops to 16A, open the spray valve at the top of the kettle, the flushing water of the discharge pipeline at the bottom of the kettle, and the flushing water of the discharge filter 1 in turn for 4 minutes, perform flushing after discharging, and pour latex and flushing water into the Store in the discharge tank 3. The measured latex pH value is 5.6, and the solid content is 43.3%. The latex in the discharge tank 3 first passes through the latex filter 4 to further filter finer slag, impurities, etc., and then passes through the second A latex delivery pump 5 is delivered to the liquid vibrating screen ...

Embodiment 2

[0061]Polymerization B zone C kettle has discharge conditions, open the plunger valve at the bottom of the kettle, and the product latex after polymerization is discharged under pressure (0.45MPaG) through the discharge pipeline at the bottom of the kettle to the discharge filter 1, the discharge time is 25min, and the material is discharged. The volume is 28.7m 3 , after the current of the discharge pump 2 drops to 16A, turn on the spray valve at the top of the kettle, rinse the discharge line at the bottom of the kettle for 3 minutes each, and rinse the water in the discharge filter 1 for 4 minutes, and pour both the latex and the rinse water into the discharge tank. 3, the latex pH value is 5.4, and the solid content is 43.7%. The latex in the discharge tank 3 is first filtered by the latex filter 4 to further filter finer slag, impurities, etc., and then the first latex delivery pump. 5. It is transported to the liquid vibrating screen 6 to filter out the particles in the ...

Embodiment 3

[0063] Polymerization C zone D kettle has discharge conditions, open the plunger valve at the bottom of the kettle, and the product latex after polymerization is discharged under pressure (0.50MPaG) through the discharge pipeline at the bottom of the kettle to the discharge filter 1, the discharge time is 23min, and the material is discharged. The volume is 28.7m 3 , after the current of the discharge pump 2 drops to 16A, turn on the spray valve at the top of the kettle, the flushing water of the discharge line at the bottom of the kettle, and the flushing water of the discharge filter 1 for 3 minutes each. After discharging, flushing is performed, and both the latex and the flushing water are injected into the It is stored in the feeding tank 3. The pH value of the latex is measured to be 5.8, and the solid content is 45.6%. A latex delivery pump 5 is transported to the liquid vibrating screen 6 to filter out the particles in the solution, and flows through the latex storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com