System for preparing polysilicon granules in fluidized bed and process for preparing polysilicon by using same

A preparation system and fluidized bed technology, applied in the preparation system of fluidized bed polycrystalline silicon particles, in the field of polycrystalline silicon preparation, can solve the problem of cyclone separator being unable to separate, avoid the decrease of heat transfer coefficient, improve the decomposition rate, and increase the contact time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

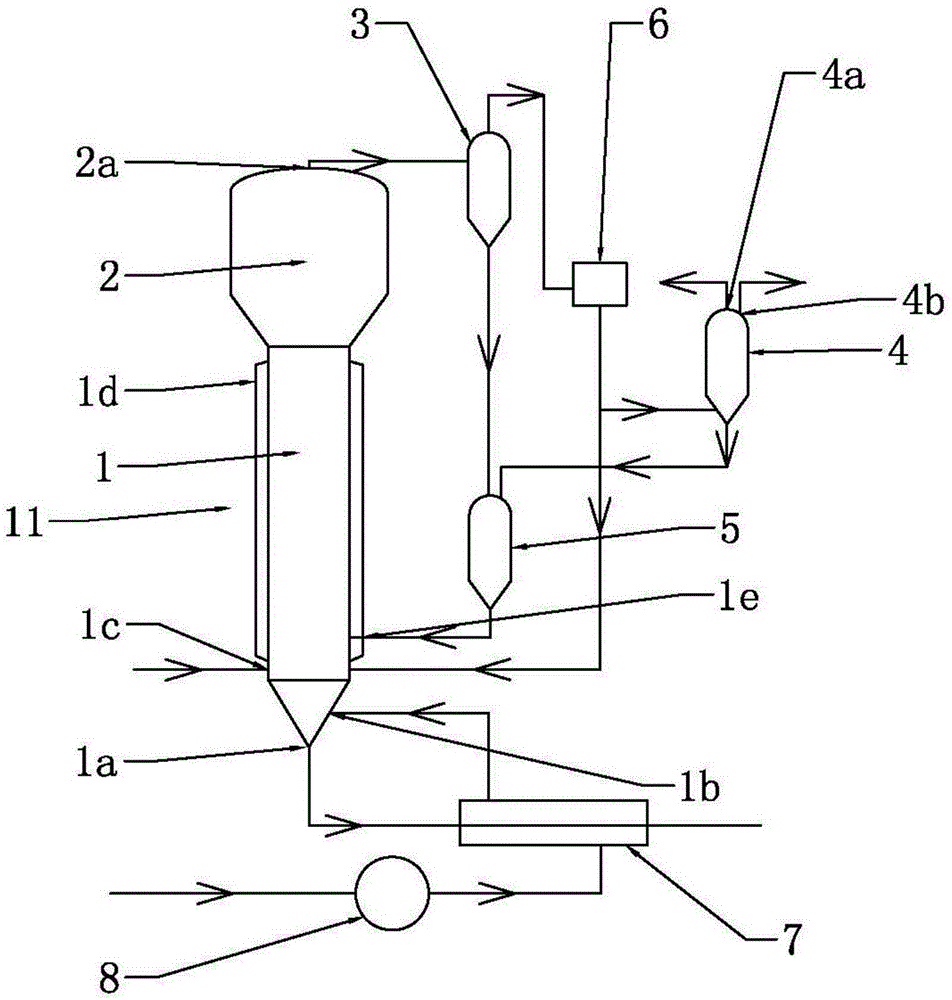

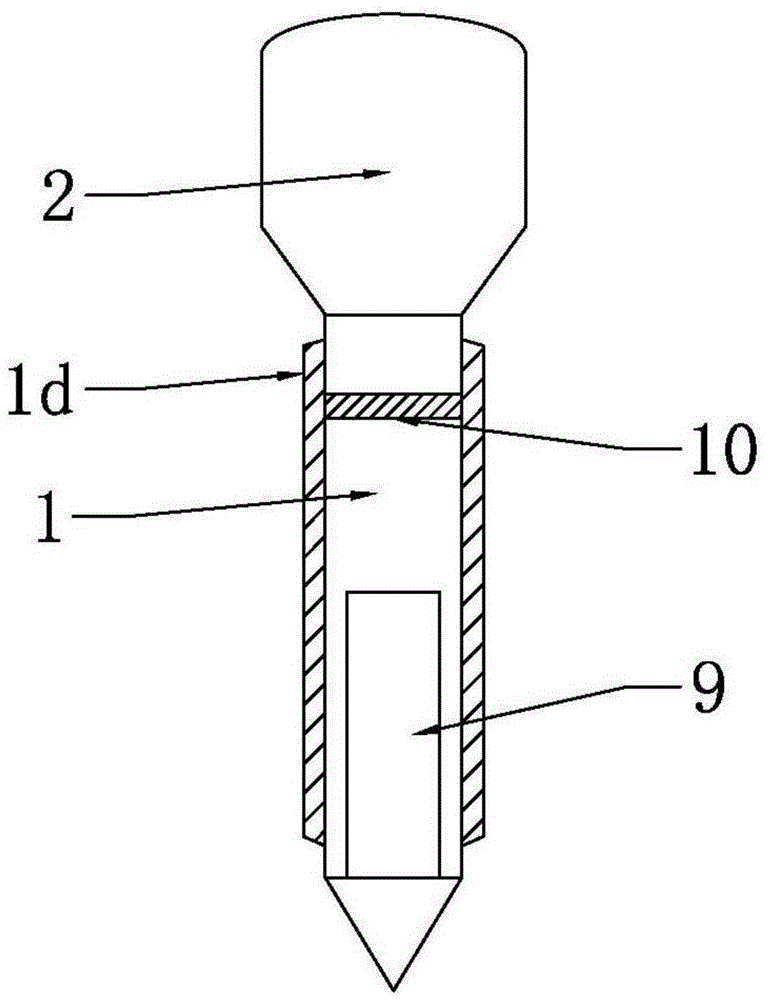

[0042] The structure of the preparation system of a fluidized bed polysilicon particle used in this embodiment also includes: the diameter of the fluidized bed expansion section 2 is 1.5 times the diameter of the fluidized bed reactor cylinder 1, and the fluidized bed expansion section 2 The connection with the fluidized bed reactor cylinder 1 is arc-shaped; the length of the fluidized bed expansion section 2 is 1 / 2 of the length of the fluidized bed reactor cylinder 1 . The angle formed by the gas flow direction of the dilution gas inlet 1c and the inner wall of the fluidized bed reactor cylinder 1 is 44 degrees. The angle formed by the gas flow direction of the dilution gas inlet 1c and the horizontal plane is 5 degrees. The fluidized bed expansion section 2 and the inner wall of the fluidized bed reactor cylinder 1 are provided with an inner lining layer with a thickness of 2mm, and the inner lining layer is made of polysilicon, high-purity quartz or high-purity graphite ma...

Embodiment 2

[0049] The structure of a fluidized bed polycrystalline silicon particle preparation system used in this embodiment also includes: the diameter of the fluidized bed expansion section 2 is twice the diameter of the fluidized bed reactor cylinder 1, and the fluidized bed expansion section 2 The connection with the fluidized bed reactor cylinder 1 is arc-shaped; the length of the fluidized bed expansion section 2 is 1 / 2 of the length of the fluidized bed reactor cylinder 1 . The gas flow direction of the dilution gas inlet 1c is tangent to the inner wall of the fluidized bed reactor cylinder 1, and the angle formed between the gas flow direction of the dilution gas inlet 1c and the horizontal plane is 8 degrees. The fluidized bed expansion section 2 and the inner wall of the fluidized bed reactor cylinder 1 are provided with an inner lining layer with a thickness of 3mm, and the inner lining layer is made of polysilicon, high-purity quartz or high-purity graphite material.

[005...

Embodiment 3

[0056] The structure of a fluidized bed polycrystalline silicon particle preparation system used in this embodiment also includes: the diameter of the fluidized bed expansion section 2 is three times the diameter of the fluidized bed reactor cylinder 1, and the fluidized bed expansion section 2 The connection with the fluidized bed reactor barrel 1 is arc-shaped; the length of the fluidized bed expansion section 2 is 1 / 3 of the length of the fluidized bed reactor barrel 1 . The angle formed by the gas flow direction of the dilution gas inlet 1c and the inner wall of the fluidized bed reactor cylinder 1 is 30 degrees. The angle formed by the gas flow direction of the dilution gas inlet 1c and the horizontal plane is 10 degrees. The fluidized bed expansion section 2 and the inner wall of the fluidized bed reactor cylinder 1 are provided with an inner lining layer with a thickness of 1mm, and the inner lining layer is made of polysilicon, high-purity quartz or high-purity graphit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com