A Method of Improving Microstructure Uniformity of gh4169 Disc Forging

A GH4169, uniform structure technology, applied in the field of forging thermal processing, can solve the problems of uneven structure of preform, affect the comprehensive performance of forgings, increase machining hours, etc., to shorten the forging process, reduce the input of raw materials, and avoid machining. The effect of billet process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

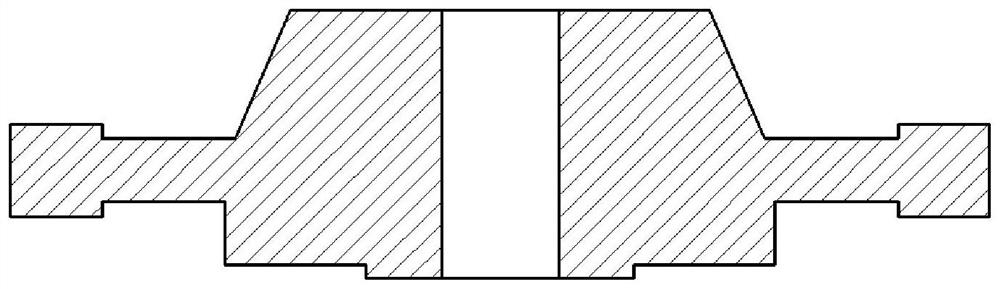

[0038] An engine low-pressure turbine disc forging, such as figure 2 As shown, the weight of the forging is 170 kg, the outer dimension of the forging is about Φ580mm×120mm, and the size of the GH4169 alloy bar used is Φ230mm×520mm.

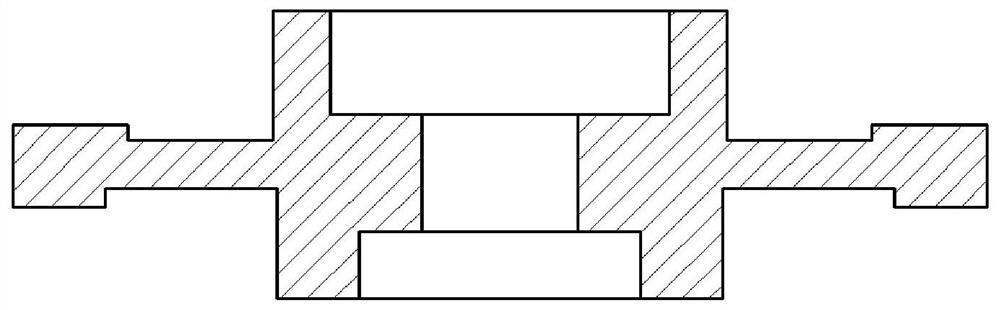

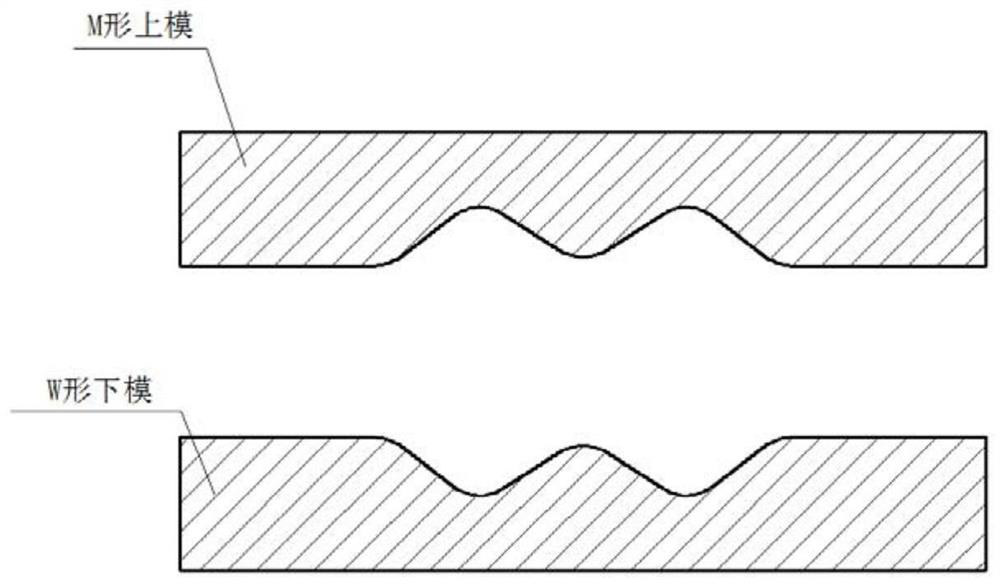

[0039] First, the design and manufacture of two sets of molds were completed, and the mold for billet making was designed. The upper mold cavity of the mold was "M" shaped, and the lower mold cavity was "W" shaped. The cavity was repeatedly optimized by numerical simulation. During the billet making process The minimum equivalent strain is about 0.25, and H13 steel is used to complete the blank mold processing; the final forging mold is designed, and the cavity is repeatedly optimized by numerical simulation. Processing of forging dies.

[0040]After spraying glass lubricant on the surface of the above-mentioned bar material, aluminum silicate fiber is used for soft sheathing, and then the bar material is heated to 1000°C by step-type heating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com