Printer

A technology for printing presses and imprinting mechanisms, applied in printing presses, rotary printing presses, printing and other directions, can solve the problems of single printing plate pattern, narrowing the scope of application of printing presses, affecting the working efficiency of equipment, etc. Improve work efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

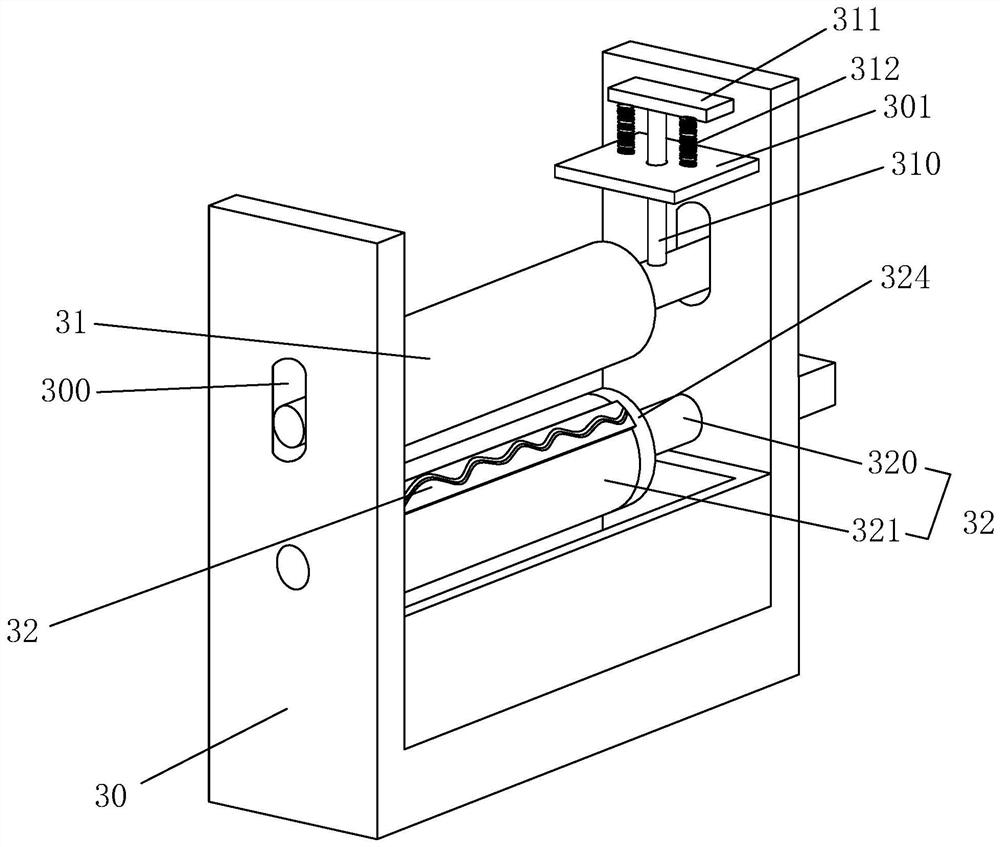

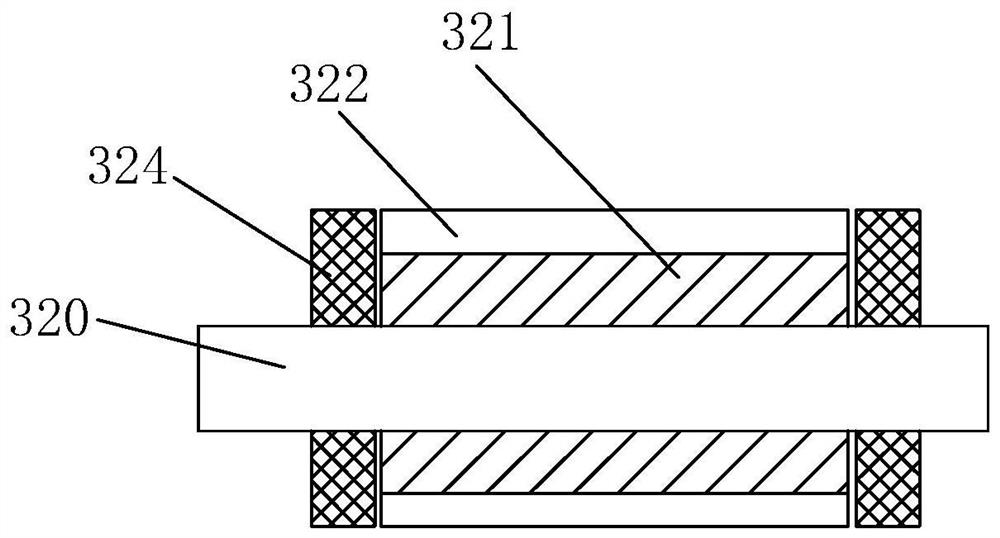

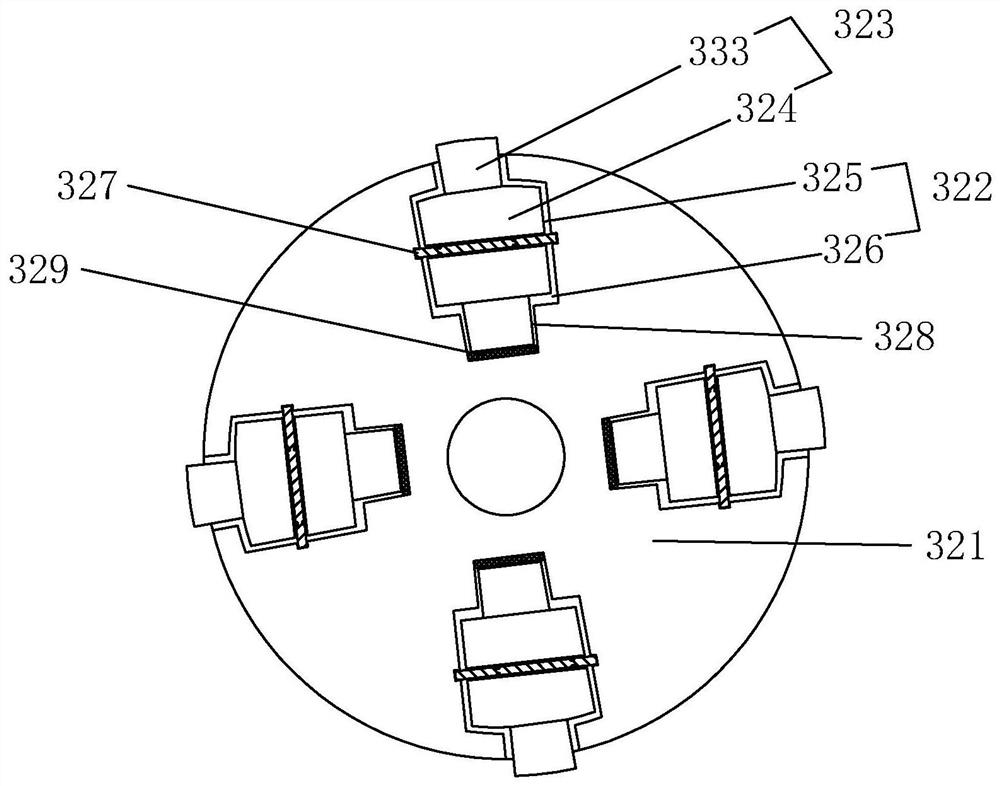

[0024] Reference Figure 1 to Figure 3 , A printing press, including a feeding mechanism, a conveying mechanism 2, an inking and embossing mechanism 3, and an unloading mechanism 4. The inking and embossing mechanism 3 includes a frame 30, a pressure roller 31 and a plate roller 32, a pressure roller 31 and Between the plate rollers 32 is formed a passage for the cardboard to pass through, the two sides of the frame 30 are respectively provided with slots 300, the pressure roller 31 is slidably arranged up and down in the slots 300, the roller shaft 320 Connecting rods 310 are provided at both ends. A support plate 301 is provided above the frame 30 corresponding to the slot 300. The support plate 301 is provided with a movable opening for the connecting rod 310 to pass through. One end of the connecting rod 310 A stopper 311 is connected after passing through the movable opening. Two compression springs 312 are provided between the stopper 311 and the supporting plate 301. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com