Quick strutting device for silk reeling and strutting method

A fast and silk technology, applied in silk reeling and other directions, can solve the problems such as the inability to fully guarantee the uniform force of the cocoon, the labor intensity of workers, and the slow work efficiency, and achieve the effect of uniform force, reducing labor intensity and speeding up work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

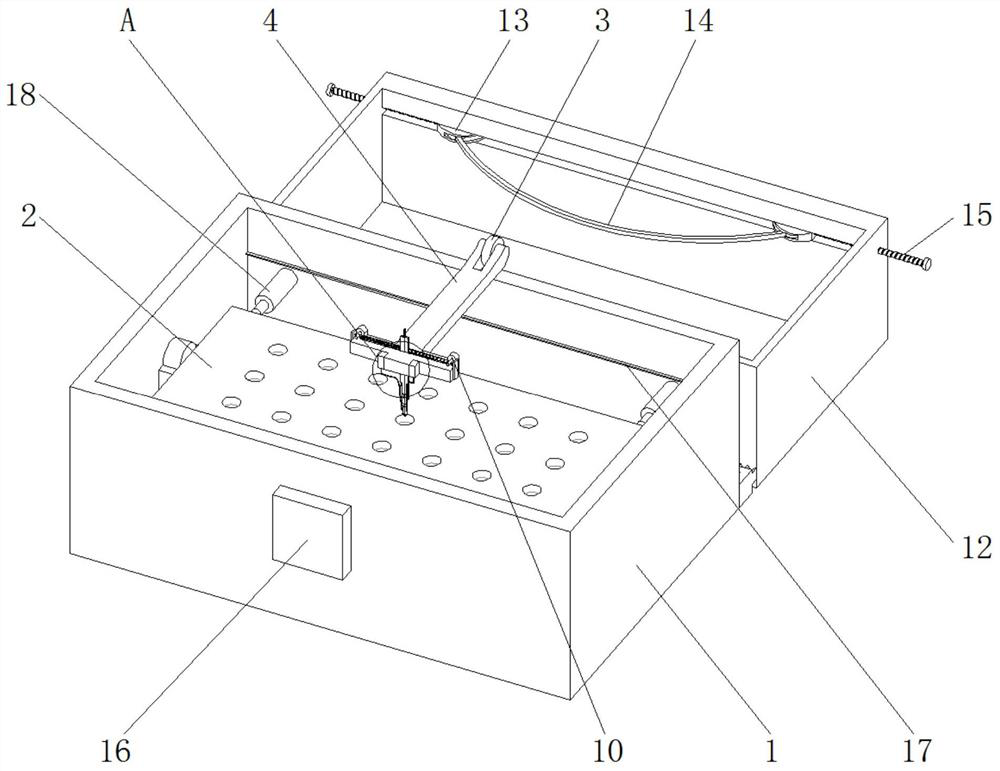

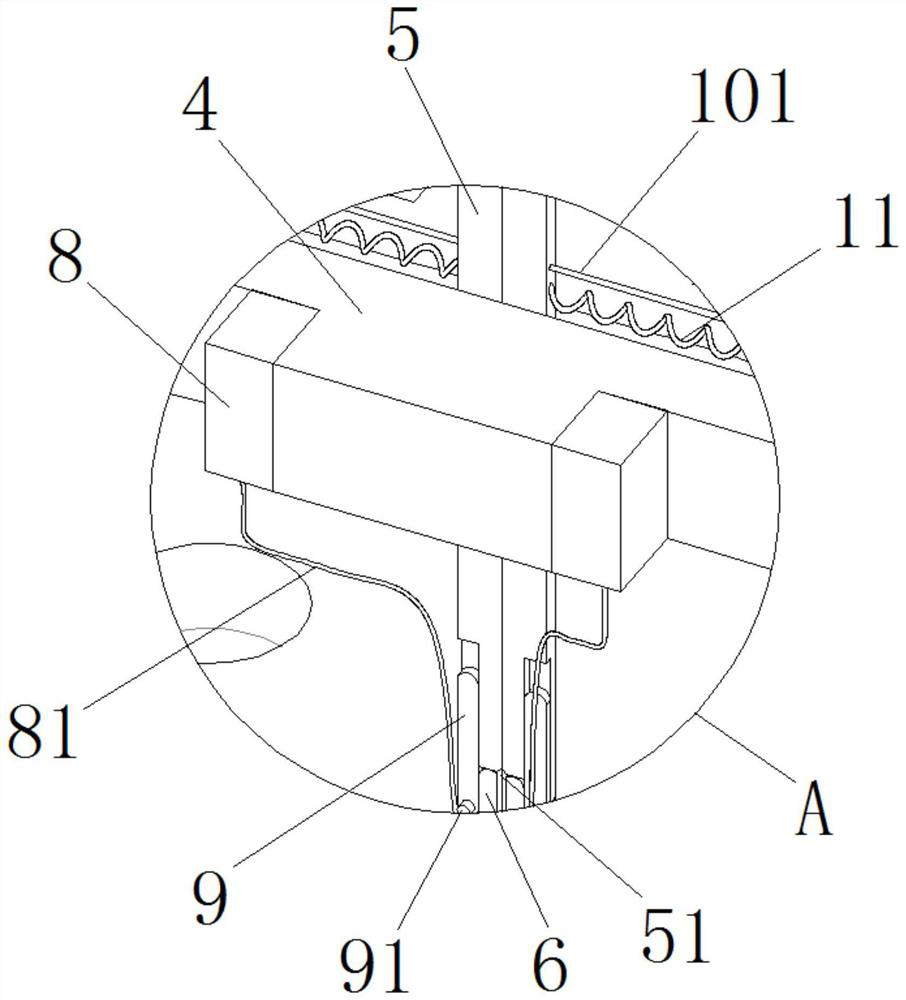

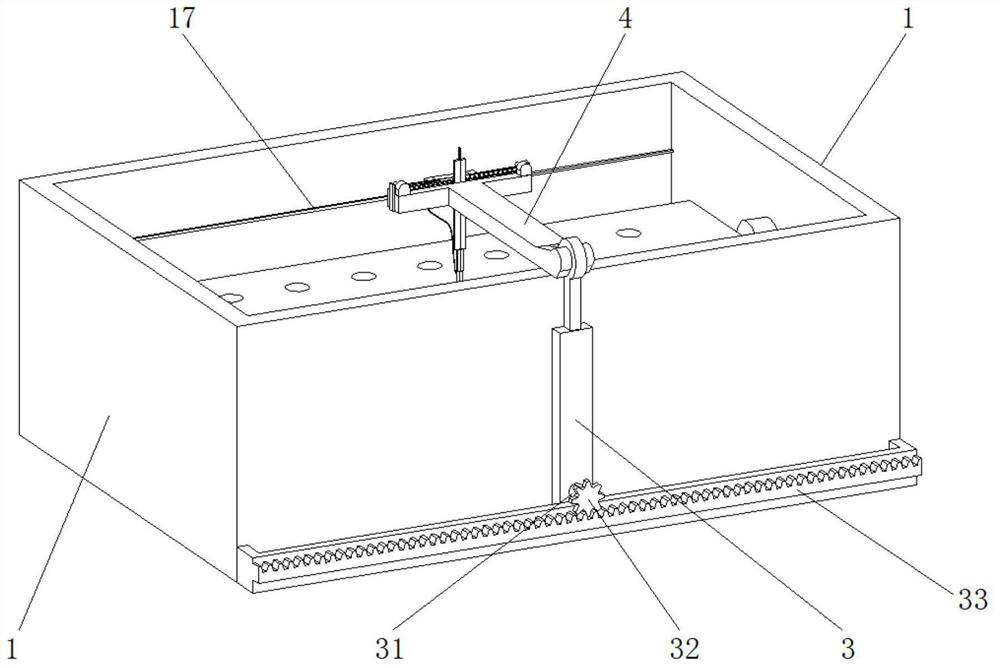

[0040] Embodiments of the present invention provide a rapid stretching device and stretching method for silk reeling, such as Figure 1-10 As shown, it includes a box body 1, a placement board 2, an electric push rod 3, a connecting board 4, two vertical rods 5, two pins 6, two balloons 7, two air pumps 8, and two clip bars 9, casing two 12 and bamboo strip 14. The placement plate 2 is slidably fitted in the casing one 1 . Placing plate 2 is used for shelving cocoons. The electric push rod-3 is slidably fitted on the back of the casing-1. The upper end of the electric push rod-3 is hinged with the connection plate 4, and the front end of the connection plate 4 can extend to the top of the placement plate 2. The two vertical rods 5 are slidingly fitted on the front end of the connecting plate 4 .

[0041] combined with Figure 4 The placement board 2 is equidistantly arranged with holes, and the bottom of the placement board 2 is welded with a net pocket 21 below the holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com