Rapid circulation construction method for upper structure of superposed beam cable-stayed bridge

A construction method and rapid cycle technology, applied in the direction of cable-stayed bridges, bridges, bridge materials, etc., can solve the problems of increasing construction costs, cracking of wet joints, etc., and achieve the effects of saving time, improving construction progress, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

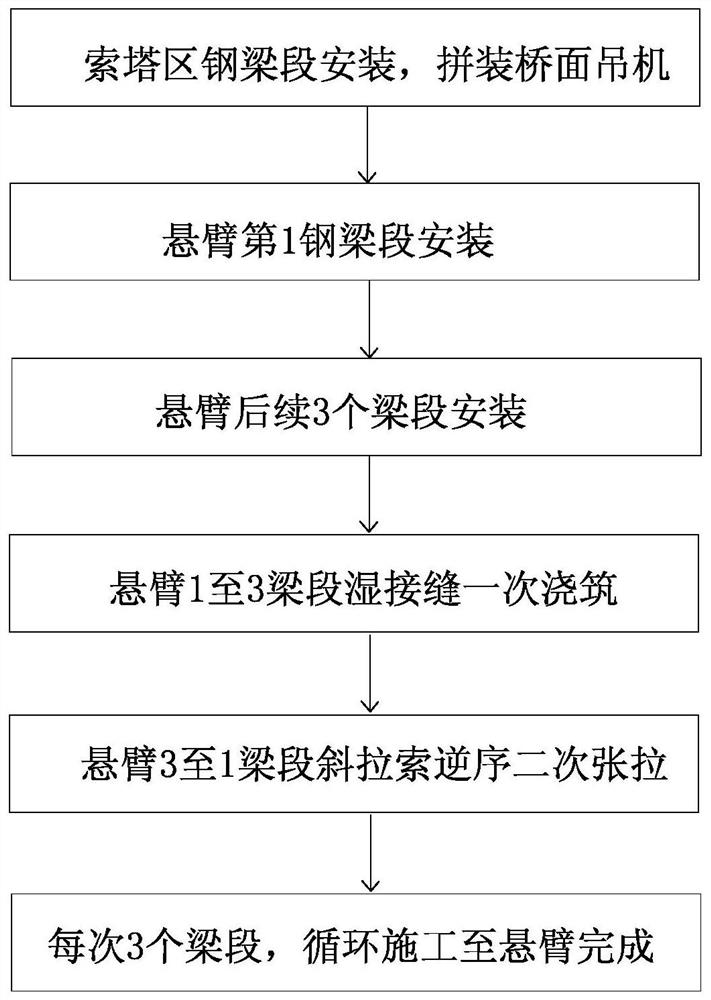

[0020] Such as figure 1 Shown, concrete construction method of the present invention is as follows:

[0021] (1) Installation of the beam section in the cable tower area: first, according to the conventional construction method, construct the bridge pier and the cable tower, install the steel beam section in the cable tower area, lay the bridge deck on the steel beam section, pour the wet joints of the bridge deck, tension Stay cables; assemble the bridge deck crane on the outermost girder section of the cable tower area;

[0022] (2) Cantilever beam section installation: Use the deck crane to lift the first steel beam section of the main girder cantilever, and weld or bolt it to the beam section where the bridge deck crane is located; The bridge deck is installed on the first beam section of the cantilever; after the installation of the beam section is completed, the stay cables are installed and tensioned for the first time, and then the deck crane moves forward to the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com