Level test system and method based on OFDR optical fiber sensing

An optical fiber sensing and testing system technology, which is applied in the field of horizontal testing systems based on OFDR optical fiber sensing, can solve the problems of inability to comprehensively obtain soil deformation characteristics, large errors in horizontal displacement data, and inaccurate judgment of sliding surfaces. The effect of comprehensive method, high monitoring accuracy and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

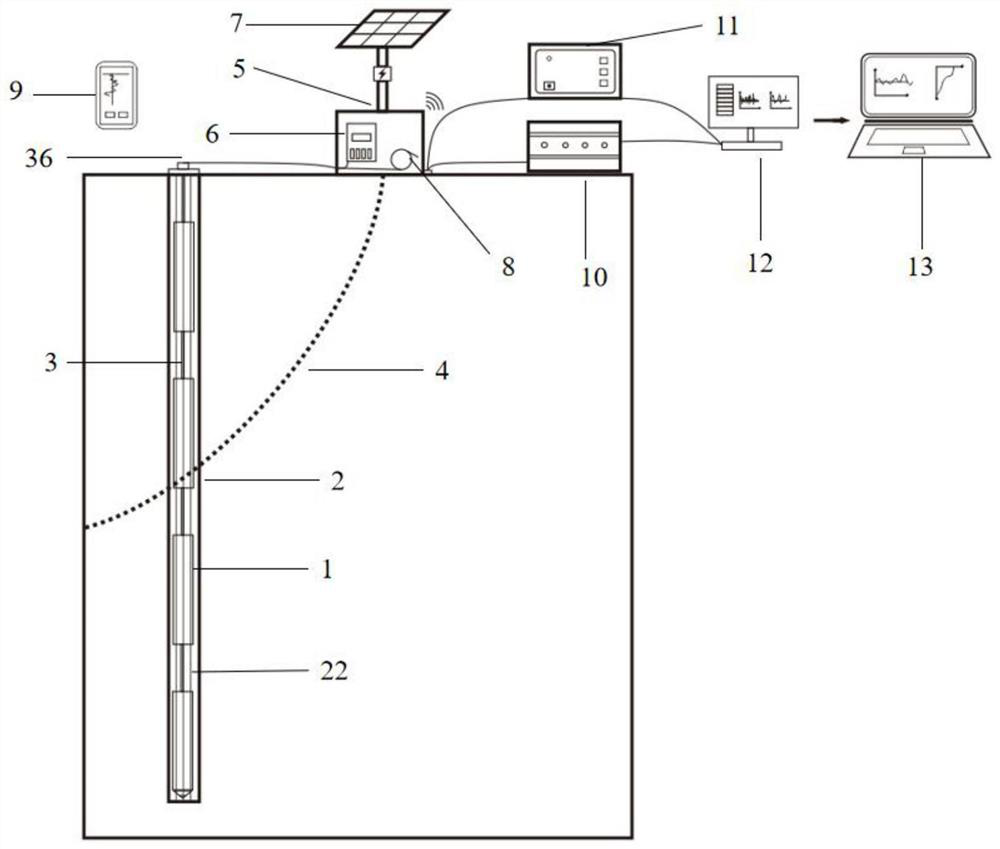

[0041]Such as figure 1 As shown, the level test system based on OFDR optical fiber sensing in the present invention includes a level test assembly, a heating sensing optical cable 22, an inclinometer data acquisition instrument 6, a photoelectric conversion module 7, a DTS demodulator 10, an OFDR optical fiber data acquisition instrument 11, Optical fiber data processing and analysis system 12 and monitoring result display and early warning system 13 .

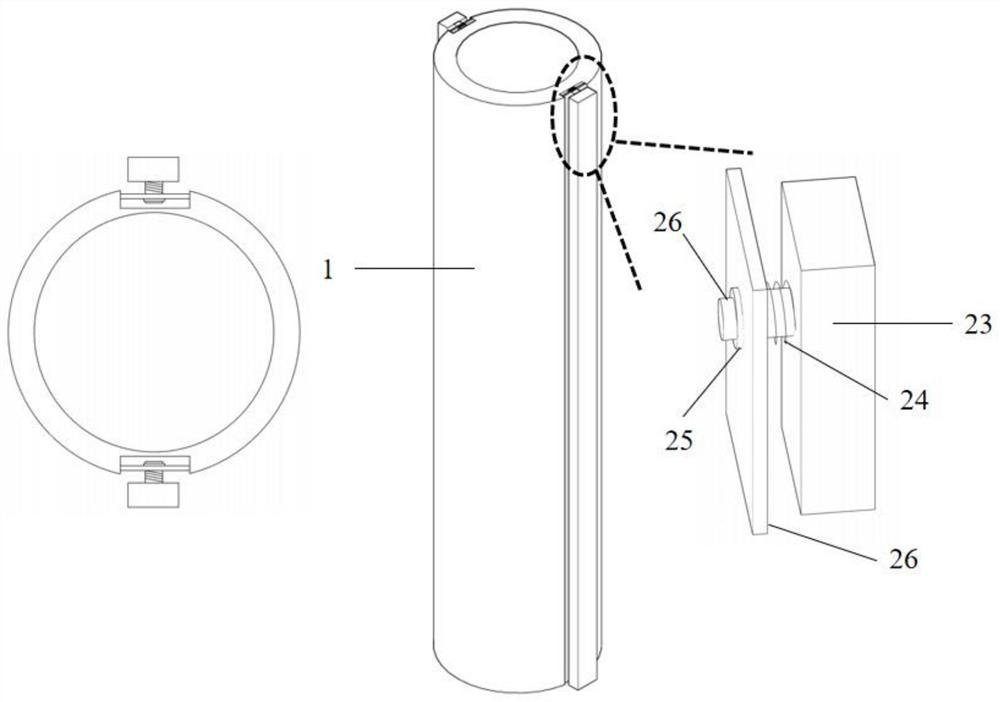

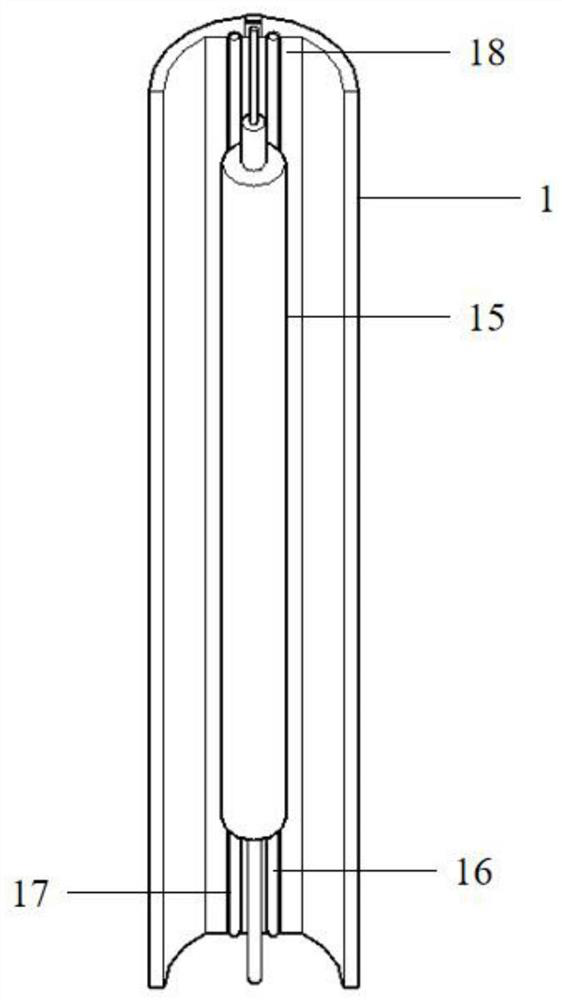

[0042] The horizontal test assembly includes a plurality of inclinometers 1 connected in series, and an inclinometer tube 2; the inside of the fixed inclinometer 1 is fixed with a distributed optical fiber strain sensor 16, a temperature compensation optical cable 17 and an acceleration sensitive element 15, and the heating sensor The optical cable 22 is laid on the surface of the inclinometer tube 2 along the axial direction.

[0043] After the inclinometer pipe 2 is buried, the series fixed inclinometer 1 is lowered along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com